070.650-IOM (JUL 19)

Page 16

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION

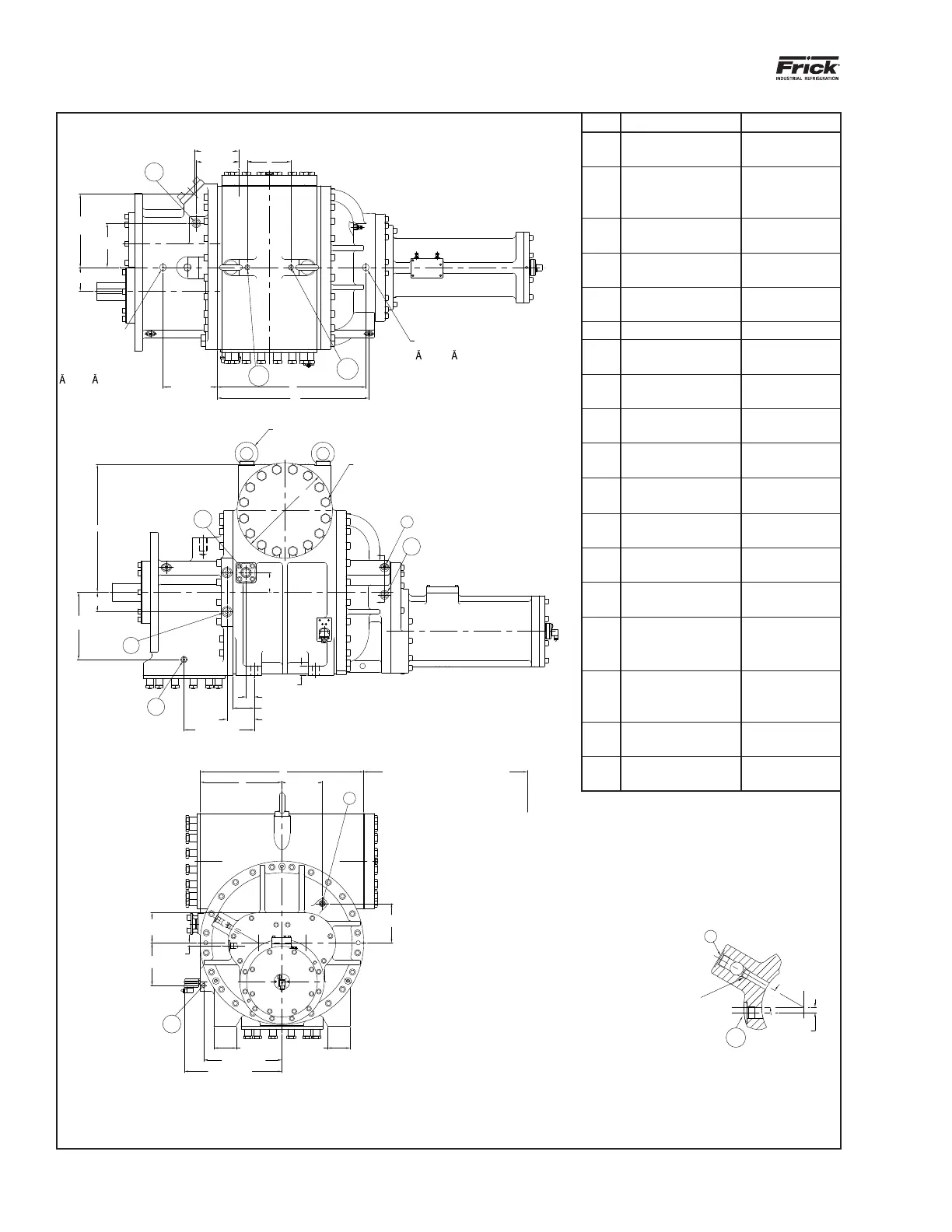

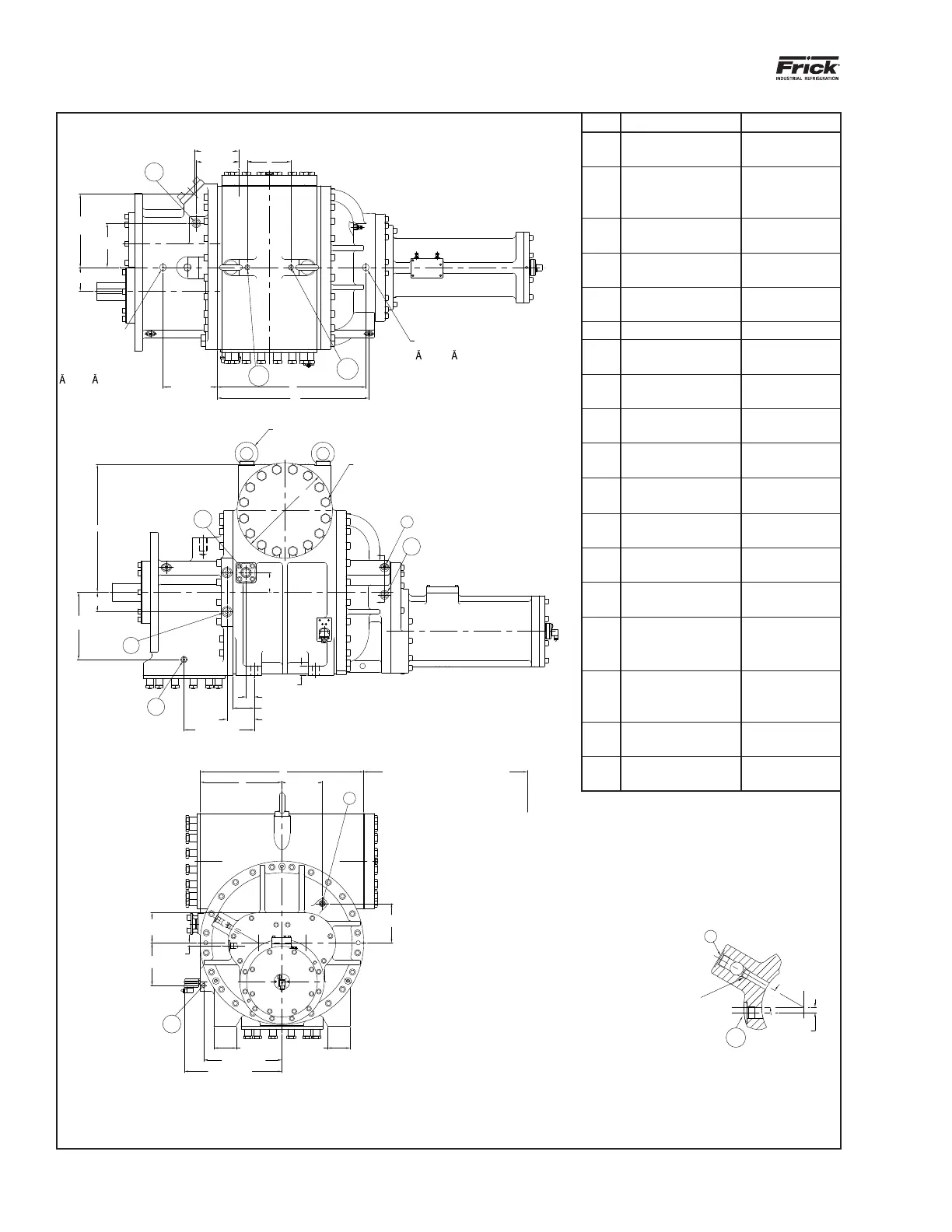

127 [5.00]

98.6 [3.88]

327.2 [12.88]

SC-6

314.5 [12.38]

91.2 [3.59]

SL-2

44.5 [1.75]

SB-3

ĂB

104.6 [4.12]

365.3 [14.38]

455.5 [17.93]

104.6 [4.12]

139.7 [5.50]

SE-1

198.6 [7.82]

341.9 [13.46]

111 [4.37]

254 [10.00]

SC-14

206.5 [8.13]

J

K

A

91.2 [3.59]

38.1 [1.50]

187.7 [7.39]

183.1 [7.21]

206 [8.11]

197.1 [7.76]

G H

SD-1

F

T

SC-5

P

SB-2

P

SB-2

W

12.7 [.50]

30Ā

12.7 [.50]

A

A

Figure 6: Port locations, SGC 2813/2817

Port Thread size (in.) Description

P

1 1/16-12 UN-2B

straight THD O-ring

Manifold block

pressure

SB-2

1 1/16-12 UN-2B

straight THD O-ring

Balance piston

and inlet bear-

ings

SB-3 1 1/14 square flange

Compressor oil

supply

SC-5

9/16-18 UNF-2B

straight THD O-ring

Inlet pressure

SC-6

9/16-18 UNF-2B

straight THD O-ring

Discharge pres-

sure

SC-7 1/8-27 NPTF Seal weepage

SC-8

1 5/16-12 UN-2B

straight THD O-ring

Closed thread

drain

SC-9

9/16-18 UNF-2B

straight THD O-ring

Inlet housing oil

drain

SC-13

9/16-18 UNF-2B

straight THD O-ring

Oil drain cylinder

SC-14

9/16-18 UNF-2B

straight THD O-ring

Liquid injection

bleed

SD-1

1 1/16-12 UN-2B

straight THD O-ring

Coalescer bleed

SE-1 1/2-14 NPTF

Electrical con-

nector

SL-1

1 5/16-12 UN-2B

straight THD O-ring

Low Vi liquid

injection

SL-2

1 5/16-12 UN-2B

straight THD O-ring

Hi Vi liquid injec-

tion

SM-1

1 5/16-12 UN-2B

straight THD O-ring

Main oil injection

SV-1 2 1/2 square ange

Vapor injection-

tongue and

groove

TE-1 3/4-14 NPTF

Suction gas tem-

perature element

T

3/4-16 UNF-2B

straight THD O-ring

Manifold block

tank

MOUNTING FOOTC

L

TRANSDUCER

MOUNTING

SPOTFACE

31.8 [ 1.25]

1.5 [.06] DP

1/4-28 UN-2B

12.7 [.50] DP

TRANSDUCER MOUNT-

ING SPOTFACE

31.8 [ 1.25]

1.5 [.06] DP

1/4-28 UN-2B

12.7 [.50] DP

SUCTION FLANGE SIZE "C" CLASS 300

ANSI FLANGE M22 X 2.5-6H THREAD (SGC2813)

38.1 [1.50] DP

M 24 X 3.0-6H THREAD (SGC2817)

44.5 [1.75] DP "D" PL

EQUALLY SPACED ON A "E" B.C.

M30 EYEBOLT FOR LIFTING (USE 2 SHOWN

WHEN MOUNTING COMPRESSOR

L

DISTANCE REQUIRED FOR

STRAINER REMOVAL

INSTALL A SOLID 1/2-14 NPTF PIPE

PLUG IN THIS LOCATION WHEN USING

PORT SB-2 FOR BALANCE PISTON AND

INLET BEARING SUPPLY.

DO NOT PLUG THIS PASSAGE IF PORT

SB-2 IS NOT PIPED. BLOCKING THIS

PASSAGE WHEN PORT SB-2 IS NOT

PIPED CAN RESULT IN A CATASTROPHIC

FAILURE DUE TO LACK OF OIL SUPPLIED

TO THE BALANCE PISTON AND INLET

BEARINGS.

SECTION A-A

SCALE 1:2

INLET END

Loading...

Loading...