070.250-IOM1 (NOV 2013)

Page 13

TDS_ Rotary Screw Compressor

Installation

The best insurance for a trouble-free installation is to

rmlyanchorthecompressortoasuitablefoundation

using proper bolting and by preventing piping stress from

being imposed on the compressor. Once the compressor

is rigged into place, its feet must be shimmed to level it.

There must be absolutely no stresses introduced into the

compressorbodyduetoboltingofthefeetandanges.

In any screw compressor installation, suction and dis-

charge lines should be supported in pipe hangers (pref-

erably within 2 ft of vertical pipe run) so that the lines

won’t move if disconnected from the compressor. See the

following table for allowableangeloads.

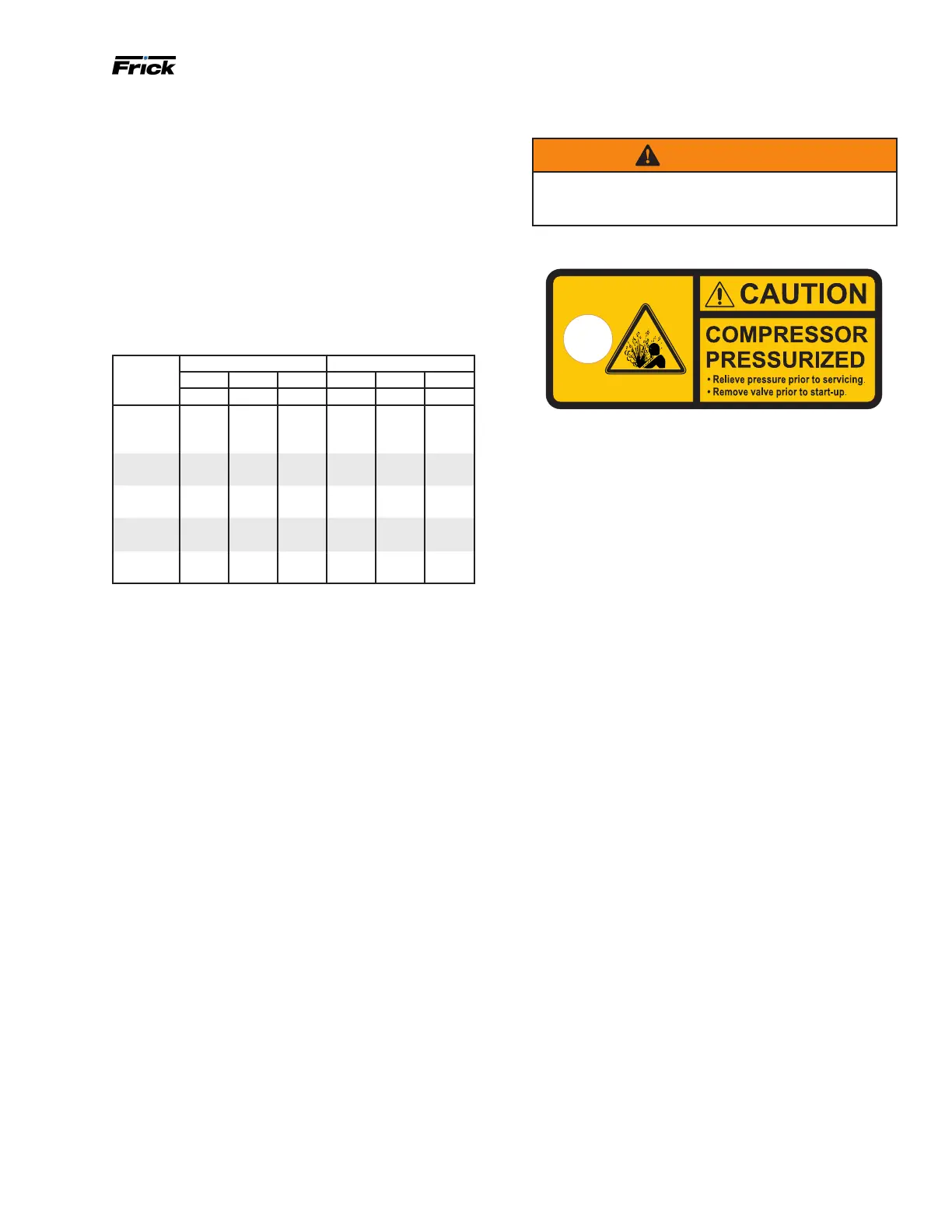

Table 4: Allowable ange loads

Noz.

size

NPS

Moments (ft-lbf) Load (lbf)

Axial Vert. Lat. Axial Vert. Lat.

M

R

M

C

M

L

P V

C

V

L

1 25 25 25 50 50 50

1.25 25 25 25 50 50 50

1.5 50 40 40 100 75 75

2 100 70 70 150 125 125

3 250 175 175 225 250 250

4 400 200 200 300 400 400

5 425 400 400 400 450 450

6 1,000 750 750 650 650 650

8 1,500 1,000 1,000 1,500 900 900

10 1,500 1,200 1,200 1,500 1,200 1,200

14 2,000 1,800 1,800 1,700 2,000 2,000

Customer connections

As a minimum you must connect to the following locations

in addition to suction and discharge.

SB-2 Inlet Bearings and Balance Piston

SB-3 Compressor oil supply

SM-1 Main oil injection

SC-1 Slide Valve Unload Port

SC-2 Slide Valve Load Port

SC-3 Volume Ratio Increase Port

SC-4 Volume Ratio Decrease Port

SD-1 Coalescer Bleed

Other connections are available for instrumentation and

service as noted on the Dimensional Outline drawing. The

electrical connections for the slide stop and the slide valve

transmitters and the solenoid valve coils must be connected

to your control system.

The oil supply system for the compressor must be de-

signed for a total pressure drop of no more than 15 psi

withanewoillterelement.Thisiscriticalfortheproper

operation of the balance piston which is used to ensure

the life of the male axial bearing. Excessive pressure drop

in the oil circuit can also prevent proper operation of the

slide valve and slide stop pistons.

Oil system requirements

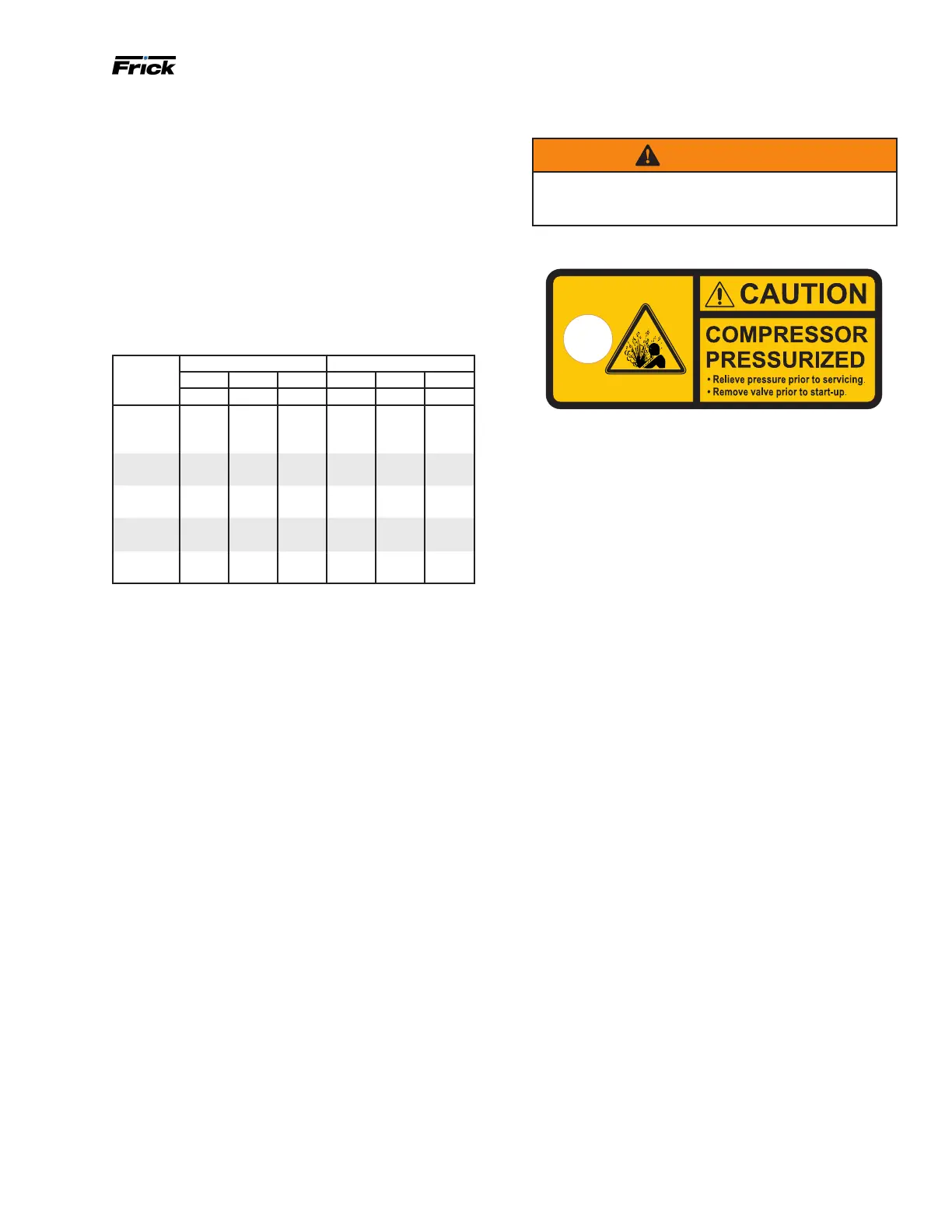

WARNING

Access valves in brass material must be removed and

the holes lled with steel plugs when package is as-

sembled.

Figure 9: Caution/identication tag on access valve

The oil system must provide oil to the compressor within

limitation on:

• Oil selection

• Oil pressure

• Oil temperature

• Oil cleanliness

Oil selection

The selected oil most be suitable for the application,

refrigerant and operation condition. The compressor

bearing require a minimum viscosity based on size and

speed, rpm. A maximum viscosity of 100 cSt should not be

exited. Frick compressor oils per 160.802-SPC are recom-

mended. Frick Coolware compressor selection program in-

clude properties for the Frick oils and provide information

on viscosity requirement for a given compressor selection.

Oil pressure

The complete oil system shall be designed for a pressure

dropnohigherthan15psiwithacleanoillterelement.

These is critical for the proper function of the balance

piston and ensure the life of the axial bearings. At booster,

low pressure and low pressure ratio operation an oil pump

mustbebuildintoprovidesufcientoilpressure.

The control system should have means to check the oil

pressure and compare to both suction and discharge pres-

sure. In general oil pressure shall be minimum (1.5 times

the suction pressure +15 psi) and higher than (discharge

pressure – 25 psi). For application with economizer and/or

sideload the oil pressure shall additional be more than 15

psi above the pressure at the side port when in operation.

Advanced control systems like the Frick Quantum will

check on the oil pressure in many more ways in order to

keep the compressor running beyond these basic lim-

its e.g. keep compressor running safely in partial loaded

condition.

Oil cooling requirements

Compressor oil needs to be cooled to control the discharge

temperature, maintain proper oil viscosity and to preserve

the life of the oil. Normally the discharge temperature will

be in the 170° to 180°F range (see CoolWare

™

).

Loading...

Loading...