070.250-IOM1 (NOV 2013)

Page 20

TDS_ Rotary Screw Compressor

Maintenance

Recommended maintenance program

In order to obtain maximum compressor performance

and ensure reliable operation, a regular maintenance

program should be followed. The compressor unit should

be checked regularly for leaks, abnormal vibration, noise,

and proper operation. A log should also be maintained.

Oil analysis should be performed on a regular basis. It is a

valuable tool that can identify the presence of moisture,

acid, metallics and other contaminants that will shorten

compressor life if not corrected. In addition, an analysis of

the compressor vibration should be made periodically.

Vibration analysis

Periodic vibration analysis can be useful in detecting

bearing wear and other mechanical failures. If vibration

analysis is used as a part of your preventive maintenance

program, take the following guidelines into consideration.

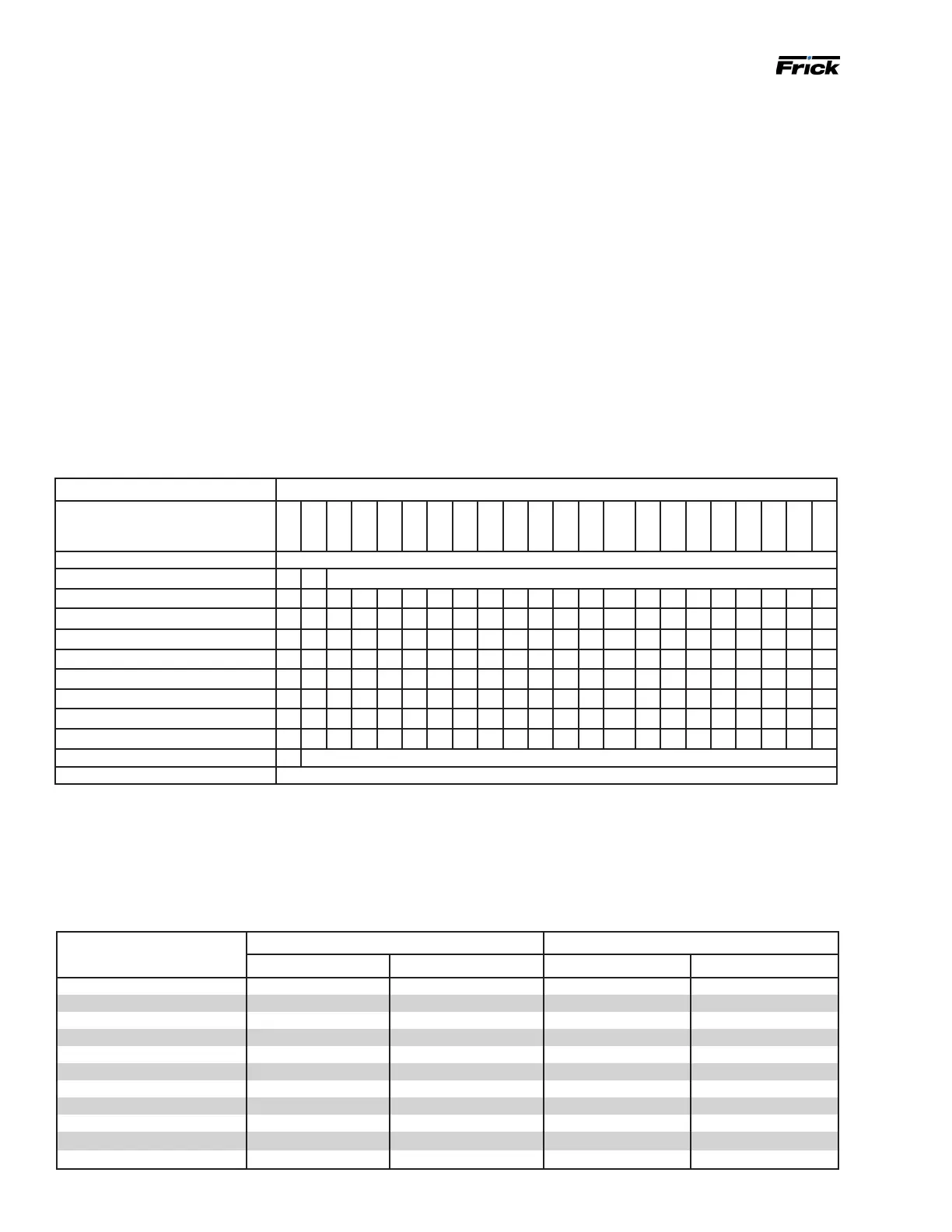

Maintenance schedule

This schedule should be followed to ensure trouble-free operation of the compressor unit.

Frequency or hours of operation (maximum)

Maintenance

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change oil As directed by oil analysis

Oil analysis

n

Every 6 months

Replace lters

n

n

n

n

n

n

n

n

n

n

n

Clean oil strainers

n

n

n

n

n

n

n

n

n

n

n

Clean liquid strainers

n

n

n

n

n

n

n

n

n

n

n

Replace coalescers

n

n

n

Check and clean suction strainer

n n n

n

n

n

n

n

n

n

n

n

Check alignment

n

n

n

n

n

n

n

n

n

n

n

Check coupling (b)

n

n

n

n

n

n

n

n

n

n

n

Suction and disch. ange bolts (c)

n n n n n n n n n n n n n n n n n n n n n n

Vibration analysis (c)

n

Every 6 months, more frequently if levels increase

Replace shaft seal When Leak rate exceeds 7 to 8 drops per minute

a. Check bolts, shim packs, center inserts, keys, and all bolt torques.

b.Verifytightnessofboltsonsuctionanddischargeanges.SeeTable 5 below for torque requirements.

c. Vibration measurement must be carried out continuously to obtain optimum preventative control on bearings. If not continuously

controlled, then every 6 months, more frequently if levels increase.

Note: Thebolttorquerequirementsforthecompressorangetoseparatorangearebasedon:

• Gaskets: Garlock

®

Blue-Gard

®

3300

• Bolts: class 8.8 or stronger hex head bolts, lightly oiled and clean

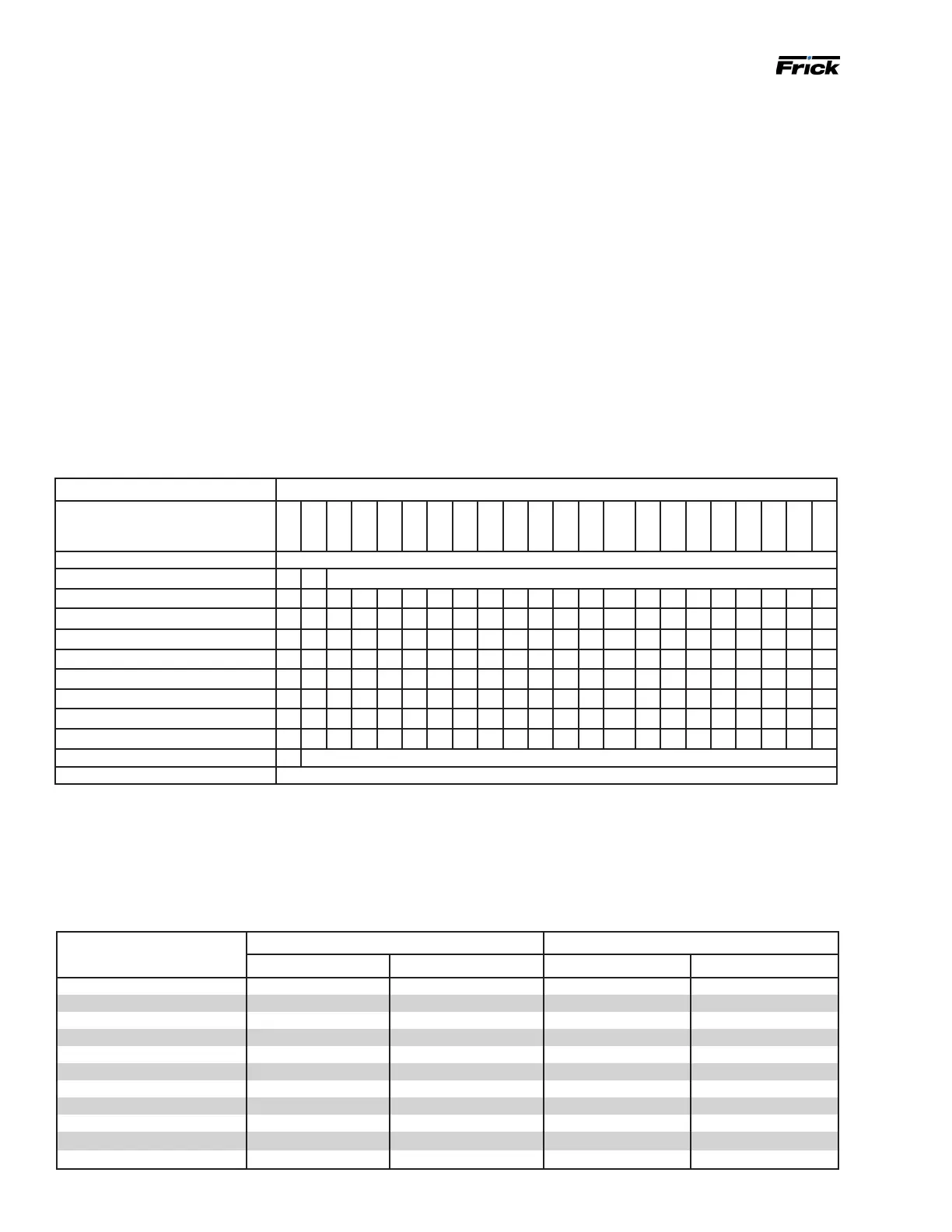

Table 5: TDSH ange bolt torque

TDS_ compressor model

Discharge ange to separator ange Suction ange

Bolt size (in.) Torque (ft-lb) Bolt size (in.) Torque (ft-lb)

163S M20 X 2.5 100 M16 X 2.0 120

163L M20 X 2.5 100 M16 X 2.0 120

193S M20 X 2.5 140 M20 X 2.5 180

193L M20 X 2.5 140 M20 X 2.5 160

233S M20 X 2.5 160 M20 X 2.5 160

233L M20 X 2.5 160 M20 X 2.5 200

233XL M20 X 2.5 160 M22 X 2.5 220

283S M22 X 2.5 230 M22 X 2.5 220

283L M22 X 2.5 230 M22 X 2.5 220

283SX M22 X 2.5 230 M24 X 3.0 220

355_

M24 X 3.0 240 M30 X 3.5 350

1. Always take vibration readings from exactly the same

places and at exactly the same percentage of load.

2. Use vibration readings taken from the new unit at

start-up as the baseline reference.

3. Evaluate vibration readings carefully as the instrument

range and function used can vary. Findings can be easily

misinterpreted.

4. Vibrationreadingscanbeinuencedbyotherequip-

ment operating in the vicinity or connected to the same

piping as the unit.

Oil quality and analysis

High quality and suitable oil is necessary to ensure com-

pressor longevity and reliability. Oil quality will rapidly de-

teriorate in systems containing moisture and air or other

contaminants. In order to ensure the quality of the oil in

the compressor unit:

Loading...

Loading...