070.250-IOM1 (NOV 2013)

Page 12

TDS_ Rotary Screw Compressor

Installation

Holding charge and storage

Every TDS_ compressor is pressure and leak tested at the

Johnson Controls–Frick factory and then thoroughly evacu-

ated and charged with dry nitrogen to ensure its integrity

during shipping and short term storage prior to installation.

All compressors must be kept in a clean, dry location

to prevent corrosion damage. Compressors that will be

stored for more than two months must have their nitro-

gen charge checked periodically (see pages in GENERAL

INFORMATION for complete instructions).

WARNING

Holding-charge shipping gauges (if mounted) are rated

for 30 psig and are for checking the shipping charge

only. They must be removed before pressure testing

and operating the system. Failure to remove these

gauges may result in catastrophic failure of the gauge

resulting in serious injury or death.

Access valves are bronze and they must be replaced

with steel plugs when package is assembled.

CAUTION

This equipment has been pressurized with nitrogen

gas. Temporary valves and gauges have been

installed.

1. Relieve pressure before opening lines or making

eld connections.

2. Remove charging valves or gauges before pressur-

izing system.

3. Refer to installation operation and maintenance

manual for additional information.

Escaping gas may cause injury.

Rigging and handling

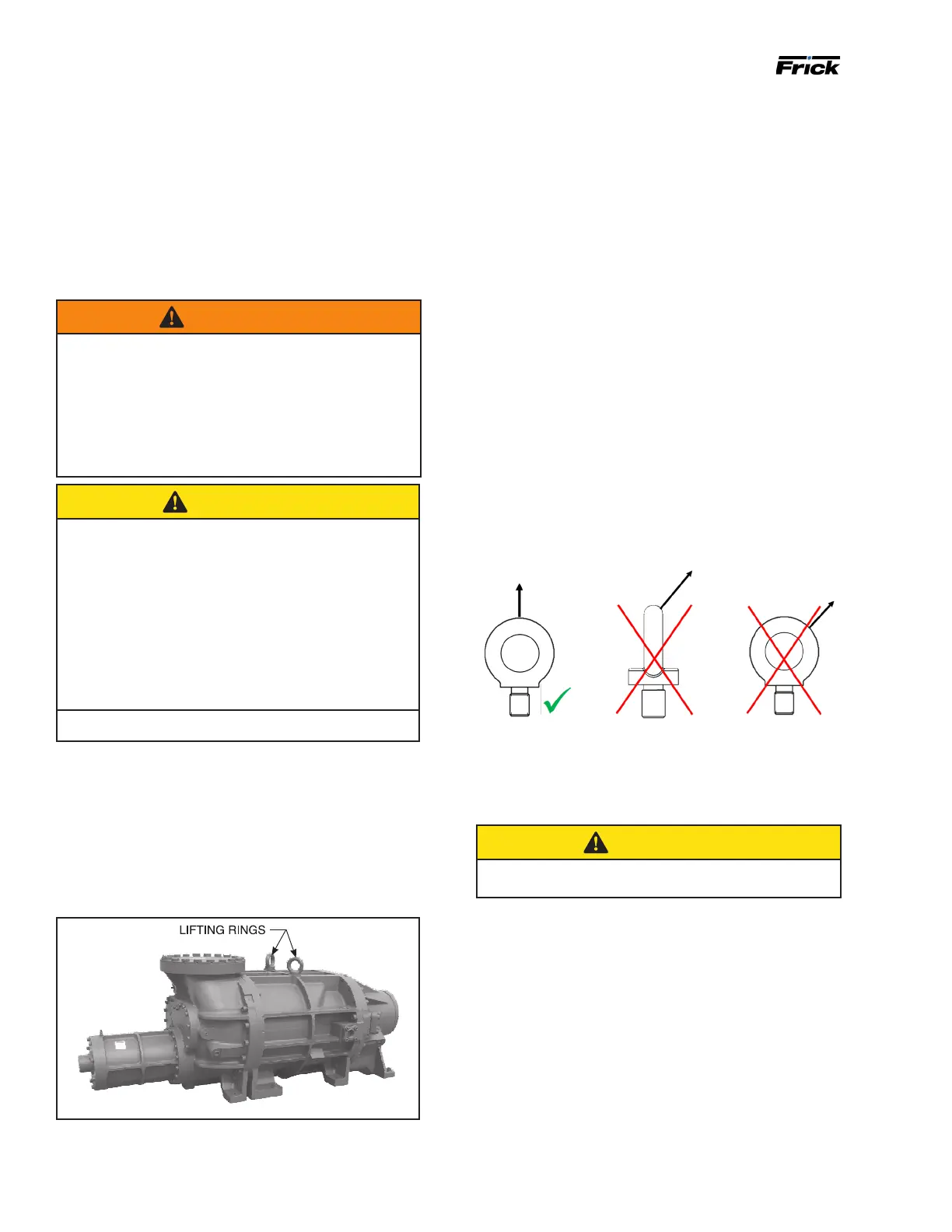

The compressor can be moved with rigging, using a crane

or forklift, by hooking into the two lifting rings on the main

housing (some models only have one ring). The compres-

sor lifting rings shall only be used to lift the compressor

itself.Seethefollowinggure.

Figure 7: Lifting rings, model 355

Lifting instructions

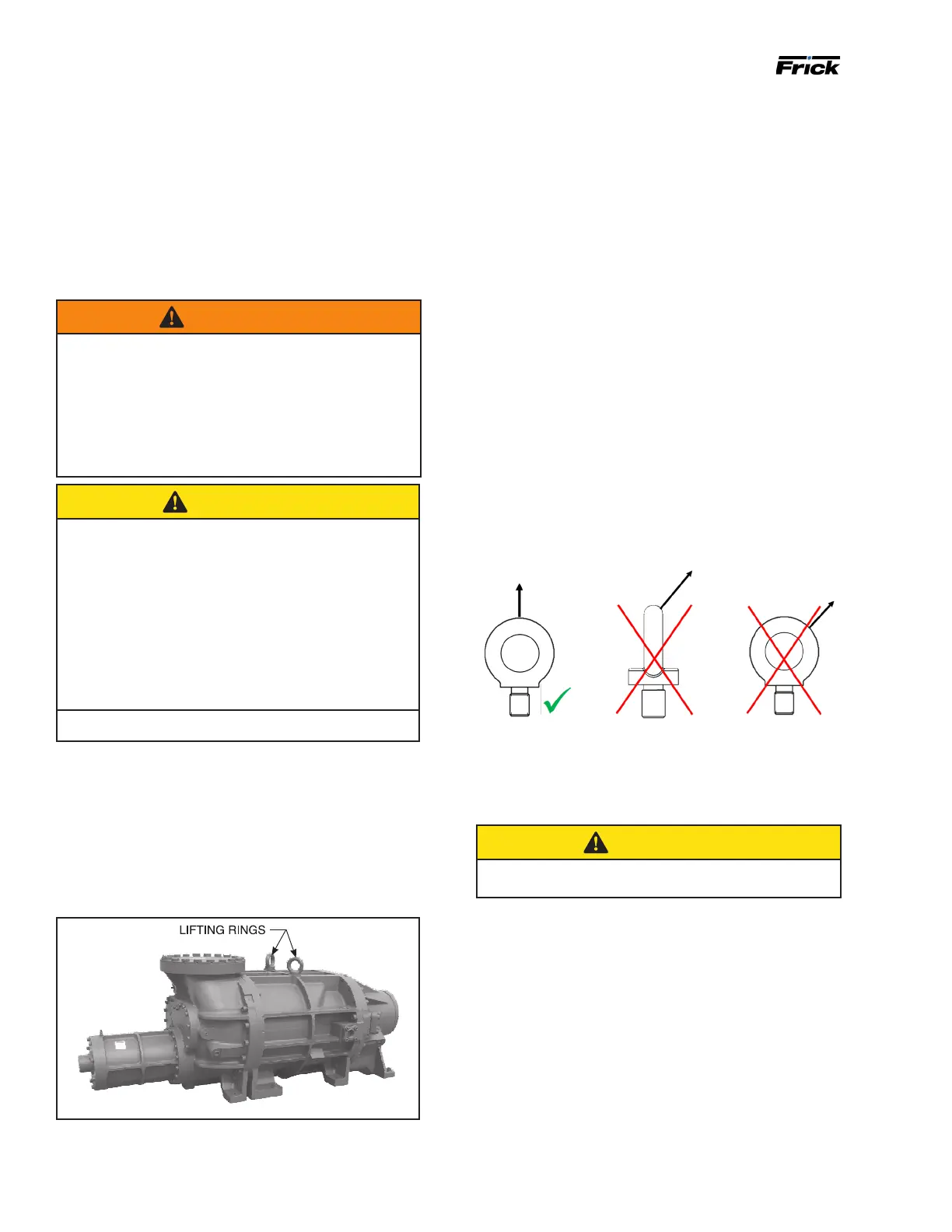

Lifting rings are located to facilitate the rigging and lifting

of the bare compressor. See Figure 8. Ensure only a quali-

edoperatorperformstheliftingandthattheyfollowthe

necessary precautions.

• Lift rings are intended for lifting the bare compressor

only.

• Examine the lift rings for damage before lifting the

compressor. Replace any damaged rings

• Fullyscrewintheliftringsandseatthemrmlyagainst

the contact surface before lifting.

• Load the lift rings in the vertical direction only; that

is, ensure the load is parallel to the threaded portion

of the lift ring. See Figure 8. This may require the use

of a spreader beam. Loading the lift rings at an angle

reduces their load capacity.

• Ensure that the load is level and stable before lifting

more than a few inches.

• Lift the compressor slowly.

• Remove the lift rings from the compressor before

operation. The vibration of a running compressor can

cause the lift rings to loosen and become damaged.

Figure 8: Lifting rings orientation

Foundation

Each

TDS_

Rotary Screw Compressor is shipped mounted

on a wooden skid, which must be removed prior to unit

installation.

CAUTION

Allow proper spacing for servicing (see Dimensional

Outline Drawing).

Therstrequirementofthecompressorfoundationisthat

it must be able to support the weight.

163S 1,220 lb 233S 2,670 lb

163L 1,280 lb 233L 2,950 lb

193S 1,720 lb 233XL 3,300 lb

193L 1,895 lb 283S 4,100 lb

355S 7,200 lb 355XL 9,200 lb

355L 8,240 lb 355U 10,200 lb

Screw compressors are capable of converting large quan-

tities of shaft power into gas compression in a relatively

small space. The compression process creates relatively

highfrequencyvibrationsthatrequiresufcientmassin

the base to effectively dampen them.

Loading...

Loading...