070.250-IOM1 (NOV 2013)

Page 16

TDS_ Rotary Screw Compressor

Installation

POT #4 on the SBC until 0% is indicated. If 0% is not at-

tainable, get as close as possible and then proceed to the

next step. The adjust ments of POT #4 and POT #3 are

interactive and POT #3 may require adjustment to allow

POT #4 to come into range.

Completely load the slide valve. The display at this time

should indicate 100%. If the display is less than 100%,

adjust potentiometer POT #3 on the SBC until 100% is

indicated.

Repeat this sequence until the slide valve indicates 0%

fully unloaded and 100% fully loaded.

Volumizer potentiometer

replacement and adjustment

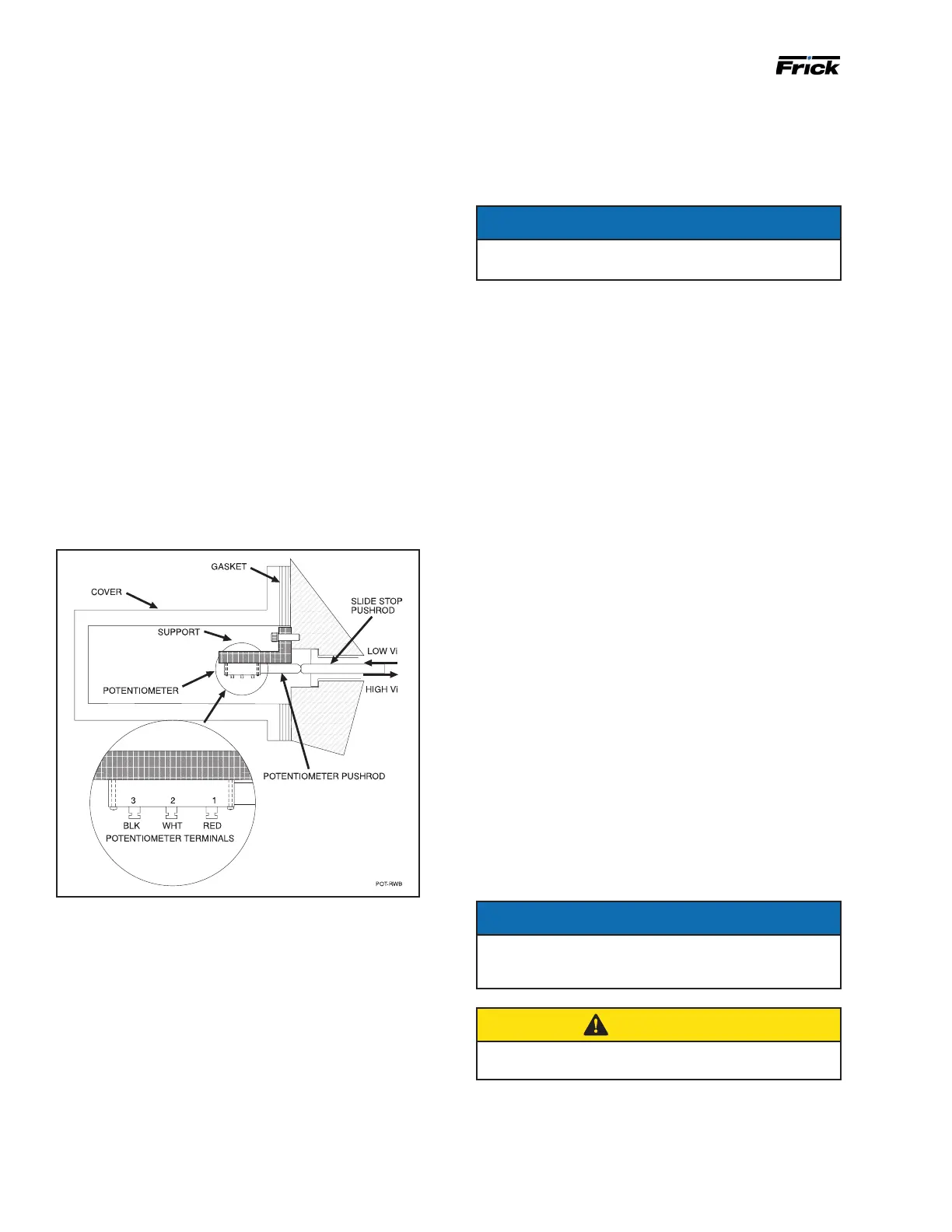

The volumizer potentiometer is located under a cover on

the right side of the compressor (facing shaft) at the inlet

end. See Figure 11.

1. Shut off control power.

2. Remove the potentiometer cover and gasket.

3. Remove the potentiometer and mounting bracket.

4. Install new potentiometer and bracket.

Figure 11: Potentiometer

5. Adjustment must be made with the compressor running

and the slide valve fully unloaded. With the slide stop

at maximum (Vi) position, check that the potentiometer

pushrod is in contact with the slide stop pushrod. If not,

the bracket must be ground or trimmed until contact is

made. Complete ly decrease the slide stop. The Operat-

ing display at this time should indicate a (Vi) of 2.2. If

greater than 2.2, adjust potentio meter POT #2 on the

SBC until 2.2 is indicated. If 2.2 is not ob tainable, get as

close as possible and proceed to the next step. Adjust-

ment of POT #2 and POT #1 are interac tive and POT #1

may require adjustment to allow POT #2 to come into

range. Now, completely increase the slide stop. The

display at this time should indicate a (Vi) of 5.0 (4.2 for

TDSH 283SX, 4.5 for TDSB 355U). If less than 5.0 (4.2 for

TDSH 283SX, 4.5 for TDSB 355U), adjust poten tiometer

POT #1 on the SBC until 5.0 (4.2 for TDSH 283SX, 4.5

for TDSB 355U) is indicated. Repeat this sequence until

the slide stop indicates 2.2 when fully decreased and

5.0 (4.2 for TDSH 283SX, 4.5 for TDSB 355U) when fully

increased.

NOTICE

The total travel on the volumizer

®

potentiometer is

.394 in.

Compressor hydraulic system

(The solenoid valves and manifold block are available as a

sales order option)

The compressor hydraulic system moves the movable

slide valve (MSV) to load and unload the compressor. It

also moves the movable slide stop (MSS) to increase or

decrease the compressor’s volume ratio (Vi).

The hydraulic cylinder located at the inlet end of the TDS

compressor serves a dual purpose. It is separated by a

xedbulkheadintotwosections.Themovableslidevalve

(MSV) sec tion is to the left of the bulkhead and the mov-

able slide stop (MSS) to the right. Both sections are con-

sidered double acting hydraulic cylinders as oil pressure

moves the pistons in either direction.

Both sections are controlled by double-acting, four-way

solenoid valves which are actuated when a signal from the

appropriate micropro cessor output energizes the solenoid

valve.

Compressor Loading: The compressor loads when MSV

solenoidYY2isenergizedandoilowsfromtheoil

manifold through valve ports P and B to cylinder port SC-2

and enters the load side of the cylinder. Simultaneously,

oilcontainedintheunloadsideofthecylinderowsout

cylinder port SC-1 through valve ports A and T to com-

pressor closed thread port.

Compressor Unloading: The compressor un loads when

MSVsolenoidYY1isenergizedandoilowsfromtheoil

manifold through valve ports P and A to cylinder port SC-1

and enters the unload side of the cylinder. Simultaneous-

ly,oilcontainedintheloadsideofthecylinderowsout

compressor port SC-2 through valve ports B and T to

com pressor closed thread port.

NOTICE

High Stage Operation: An alternative piping arrange-

ment has been provided to increase slide valve response

time during high stage operation.

CAUTION

Never open valve 1 and valve 2 at the same time during

compressor operation.

Higher operating pressures will slow the com pressor

unloading response time. Unloading response time can be

increased by closing valve 1 (oil manifold pressure) and

opening valve 2 to compressor suction pressure. See Figure

13.

Loading...

Loading...