070.250-IOM1 (NOV 2013)

Page 25

TDS_ Rotary Screw Compressor

Maintenance

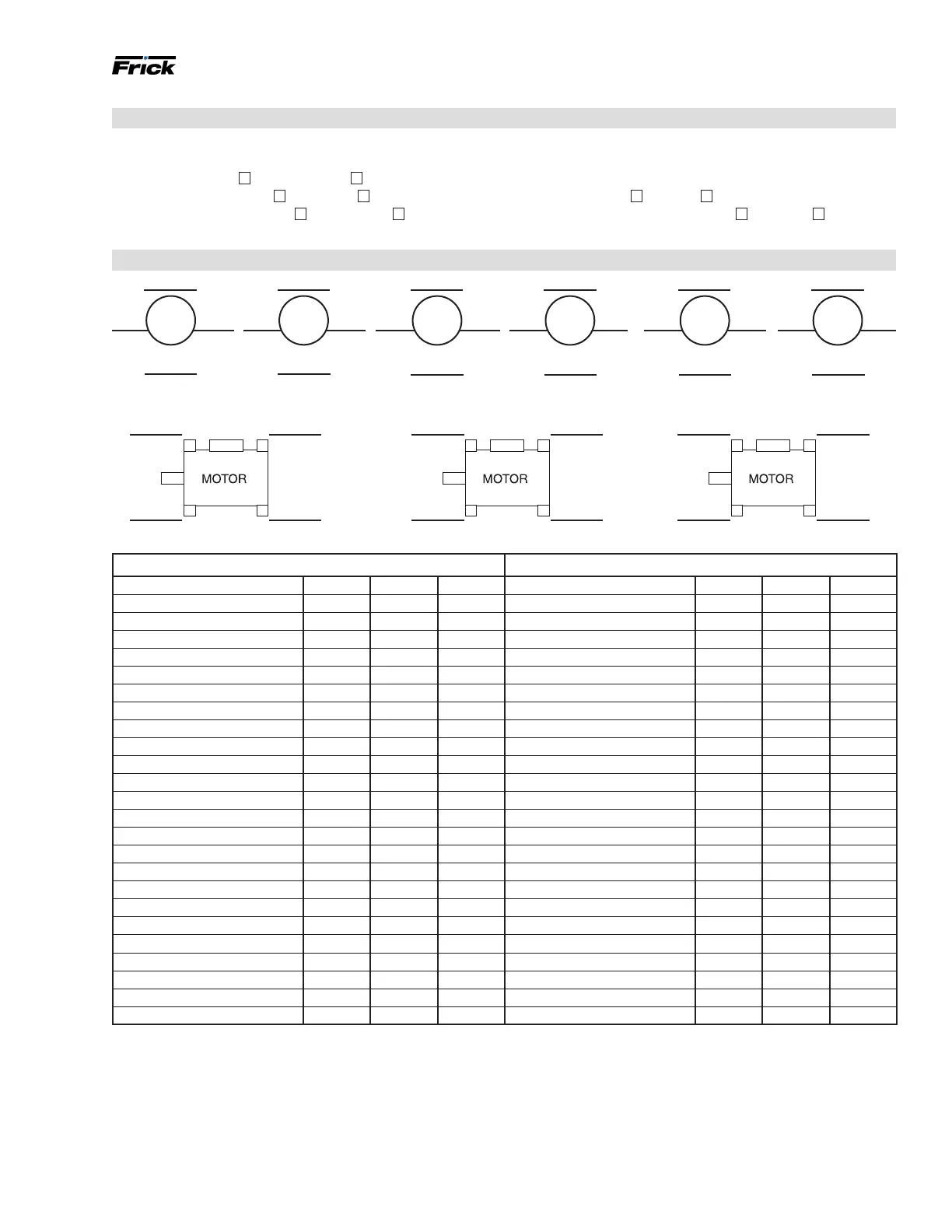

Compressor operating log sheet Starter operating log sheet

Date Average current

Time Current phase A

Hour meter reading Current phase B

Equip. room temp. Current phase C

Suction pressure Full load amps

Suction temperature Output frequency

Suction superheat Output voltage

Discharge pressure DC bus voltage

Discharge temperature Input power kW

Corresponding temperature Actual speed

Oil pressure Speed command

Oil temperature Ambient temp °F

Oillterpressuredrop Convert heatsink temp. °F

Separator temperature Baseplate temp. °F

Slide valve position VSD operating mode

Volume ratio (VI) Harmoniclterpresent

Motor amps / FLA % Harmonicltermode

Capacity control setpoint Water pump energized

Oil level Precharge relay energized

Oil added Trigger SCR’s energized

Seal leakage (drops/min.) DC inverter link current

Evaporator. EWT F. Motor winding temp. °F

Evaporator LWT F. Humidistat % RH

Condenser EWT F. Vyper coolant temp. °F

Condenser LWT F. Total kWh

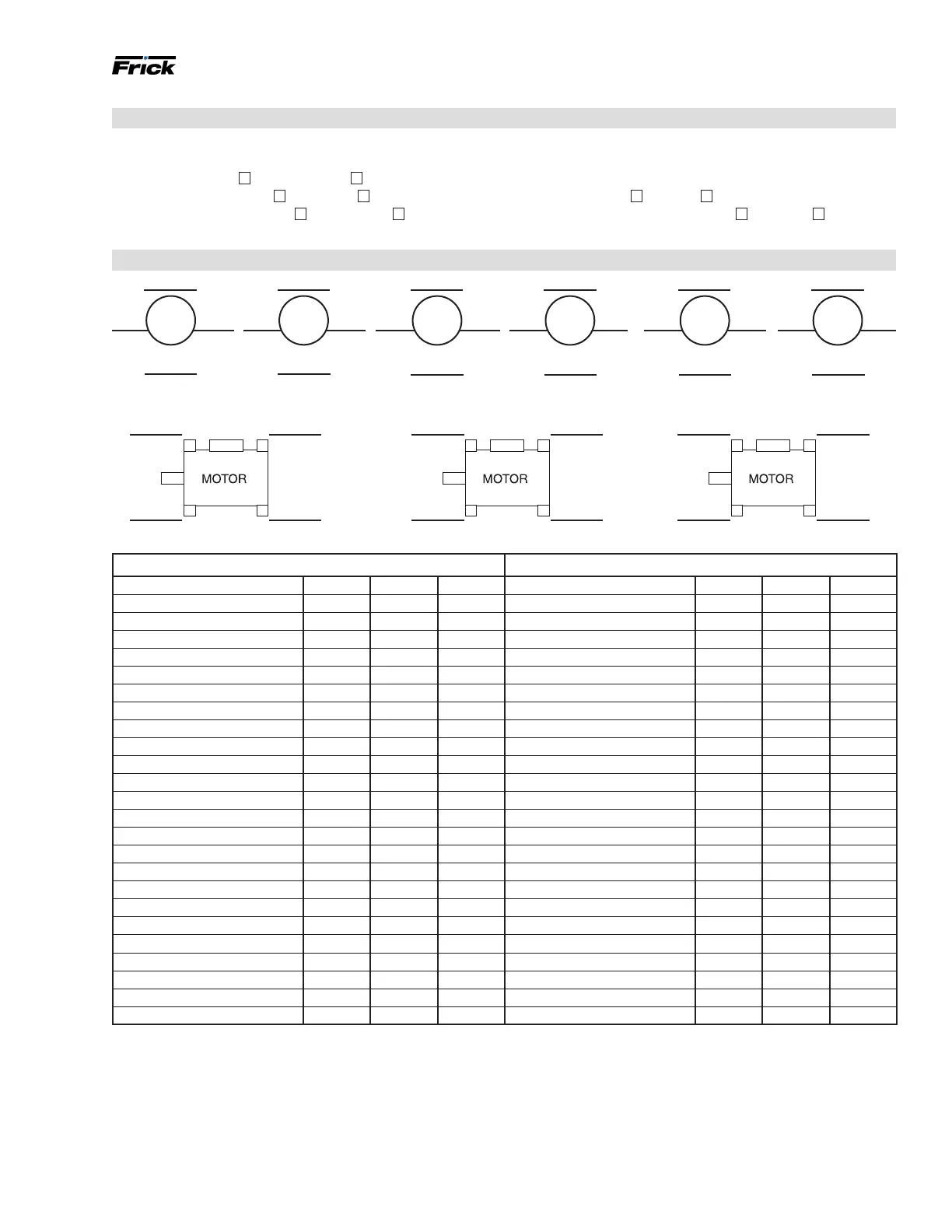

Drive train alignment

Ambient Temperature at Time of Alignment __________ Oil Separator Temperature at Time of Alignment _____________

Motor Coupling Type ______________Size ______________Distance Between Coupling Hub Faces _______________

Soft Foot Check OK as Found Shimming Required Amount of Shims used to Correct ______________

Indicator Readings in in./1000 mm Indicator Clamped to Motor Compressor

Indicator Readings Facing Compressor Motor Magnetic Center Checked Marked N/A

Compressor Coupling Hub Runout _______________ Motor Coupling Hub Runout ________________

Initial cold alignment Initial hot alignment Final hot alignment

Face Rim

Thickness of shims added

Face Rim

Thickness of shims added

Face Rim

Thickness of shims added

Loading...

Loading...