En-7

4.2. Pipe requirement

CAUTION

• Referto the Installation Manualof the outdoor unitfor description of thelength of

connecting pipe or for difference of its elevation.

• Usepipewithwater-resistantheatinsulation.

CAUTION

• Install heat insulation around both the gas and liquid pipes. Failure to do so may

cause water leaks.

Useheatinsulationwithheatresistanceabove120°C.(Reversecyclemodelonly)

In addition, if the humidity level at the installation location of the refrigerant piping is

expectedtoexceed70%,installheatinsulationaroundtherefrigerantpiping.Ifthe

expectedhumiditylevelis70-80%,useheatinsulationthatis15mmorthickerand

iftheexpectedhumidityexceeds80%,useheatinsulationthatis20mmorthicker.

Ifheatinsulationisusedthatisnotasthickasspecied,condensationmayformon

the surface of the insulation. In addition, use heat insulation with heat conductivity of

0.045W/(m·K)orless(at20°C).

4.3. Flare connection (Pipe connection)

WARNING

• Tightenthe are nuts with a torque wrench using the specied tighteningmethod.

Otherwise,thearenutscouldbreakafteraprolongedperiod,causingrefrigerantto

leakandgenerateahazardousgasiftherefrigerantcomesintocontactwithaame.

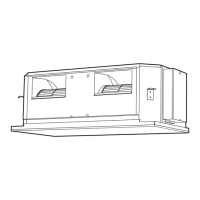

4.3.1. Flaring

• UsespecialpipecutterandaretoolexclusiveforR410A.

(1)

Cuttheconnectionpipetothenecessarylengthwithapipecutter.

(2)

Hold the pipe downward so that cuttings will not enter thepipe and remove any

burrs.

(3)

Insertthearenut(alwaysusethearenutattachedtotheindoorandoutdoorunits

respectively)ontothepipeandperformtheareprocessingwithaaretool.Use

thespecialR410Aaretool,orthe conventionalaretool. Leakageofrefrigerant

mayresultifotherarenutsareused.

(4)

Protectthepipesbypinchingthemorwithtapetopreventdust,dirt,orwaterfrom

entering the pipes.

Die

Pipe

A

B

Checkif[L]isareduniformly

and is not cracked or scratched.

Pipe outside diameter

[mm (in.)]

Dimension A [mm]

Dimension B

-

0

0.4

[mm]

Flare tool for R410A,

clutch type

6.35(1/4)

0to0.5

9.1

9.52(3/8) 13.2

12.70(1/2) 16.6

15.88(5/8) 19.7

19.05(3/4) 24.0

Whenusing conventional are tools to are R410Apipes, the dimensionAshould be

approximately0.5mmmorethanindicatedinthetable(foraringwithR410Aaretools)

toachievethespeciedaring.UseathicknessgaugetomeasurethedimensionA.

Width across

ats

Pipe outside

diameter [mm (in.)]

Width across flats

of Flare nut [mm]

6.35(1/4) 17

9.52(3/8) 22

12.70(1/2) 26

15.88(5/8) 29

19.05(3/4) 36

4.3.2. Bending pipes

•

If pipes are shaped by hand, be careful not to collapse them.

•

Donotbendthepipesinananglemorethan90°.

•

When pipes are repeatedly bend or stretched, the material will harden, making it

difculttobendorstretchthemanymore.

•

Do not bend or stretch the pipes more than 3 times.

CAUTION

• To prevent breaking of the pipe, avoid sharp bends.

• If the pipe is bent repeatedly at the same place, it will break.

4.3.3. Pipe connection

CAUTION

• Be sure to install the pipe against the port on the indoor unit correctly. If the centering

isimproper,thearenutcannottightensmoothly.Ifthearenutisforcedtoturn,the

threads will be damaged.

• Do not removethe flare nut fromthe indoor unit pipe until immediatelybefore

connecting the connection pipe.

• Holdthetorquewrenchatitsgrip,keepingitatarightanglewiththepipe,inorderto

tightenthearenutcorrectly.

• Tightentheare nutswith a torquewrench using thespecied tightening method.

Otherwise,thearenutscouldbreakafteraprolongedperiod,causingrefrigerantto

leakandgenerateahazardousgasiftherefrigerantcomesintocontactwithaame.

• Connectthepipingsothatthecontrolboxcovercaneasilyberemovedforservicing

when necessary.

• Inordertopreventwaterfromleakingintothecontrolbox,makesurethatthepiping

is well insulated.

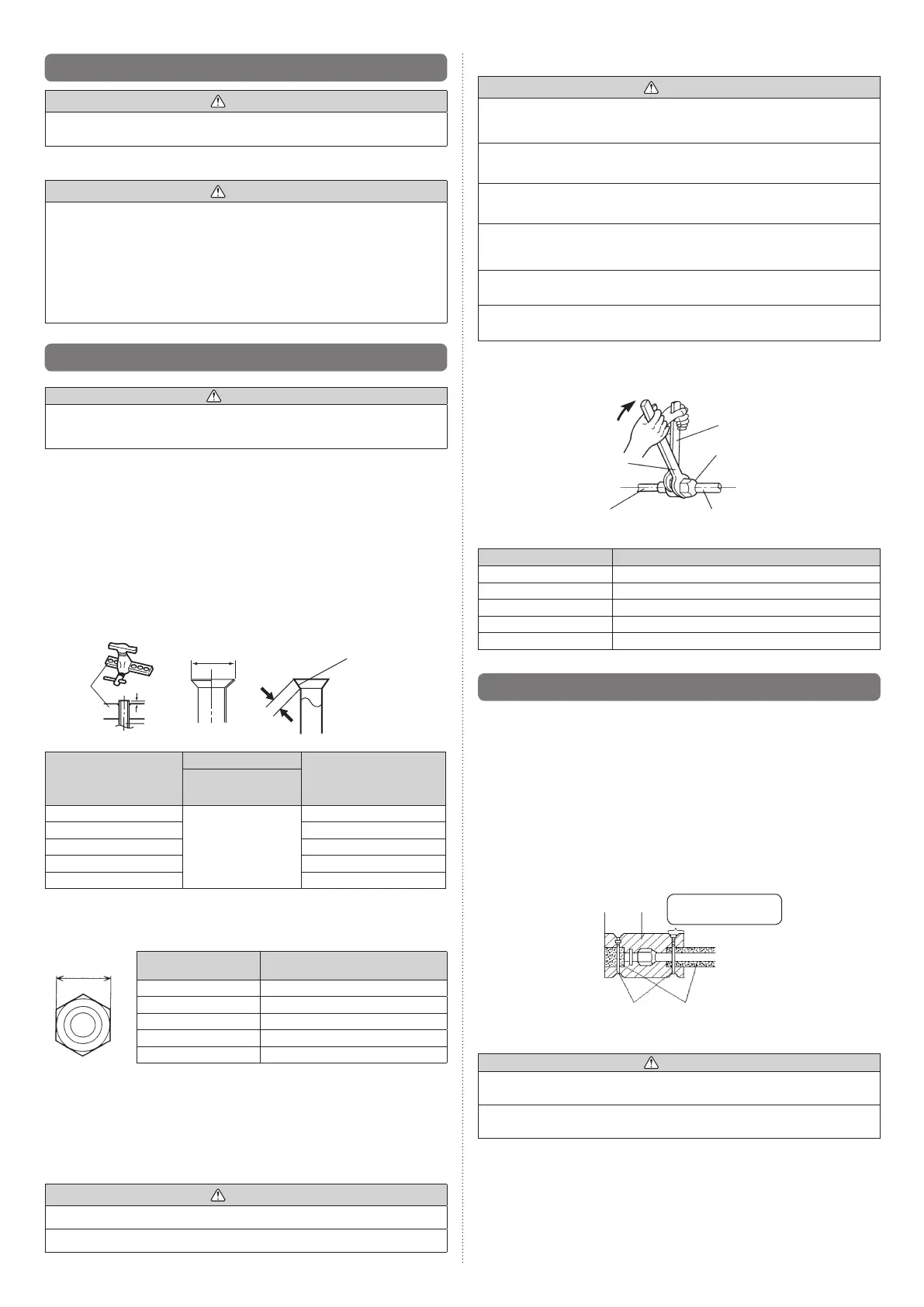

Whenthearenutistightenedproperlybyyourhand,holdthebodysidecouplingwith

aseparatespanner,thentightenwithatorquewrench.(Seethetablebelowfortheare

nuttighteningtorques.)

Tighten with 2 wrenches.

Holdingwrench

Flare nut

Connectionpipe

Torque wrench

Indoor unit pipe

(Bodyside)

Flare nut [mm (in.)] Tightening torque [N·m (kgf·cm)]

6.35(1/4)dia. 16to18(160to180)

9.52(3/8)dia. 32to42(320to420)

12.70(1/2)dia. 49to61(490to610)

15.88(5/8)dia. 63to75(630to750)

19.05(3/4)dia. 90to110(900to1,100)

4.4. Installing heat insulation

Install the heat insulation material after performing a refrigerant leak check (see the

InstallationManualfortheoutdoorunitfordetails).

4.4.1. COUPLER HEAT INSULATION

• Insulatewiththecouplerheatinsulation(Accessories)aroundthegaspipeandliquid

pipe at indoor unit.

• Afterinstallingthecouplerheatinsulation,wrapbothendswithvinyltapesothat

there is no gap.

• Afterafxingthecouplerheatinsulation,secureitwith2binders(large),oneoneach

end of the insulation.

• Makesurethatthebindersoverlaptheheatinsulationpipe.

Couplerheat

insulation

(Accessories)

Coverthisportionwith

heat insulation.

Binder(Large)

(Accessories)

Heatinsulation

CAUTION

• Afterchecking for gas leaks (refer to the Installation Manual of the outdoor unit),

perform this section.

• Installheatinsulationaroundboththelarge(gas)andsmall(liquid)pipes.Failureto

do so may cause water leaks.

9374815173-04_IM.indb 7 9/21/2011 1:45:21 PM

Loading...

Loading...