FT-C Vertical Electric Thermal Fluid Heater Manual 12 2013 ISSUE 1

20

23

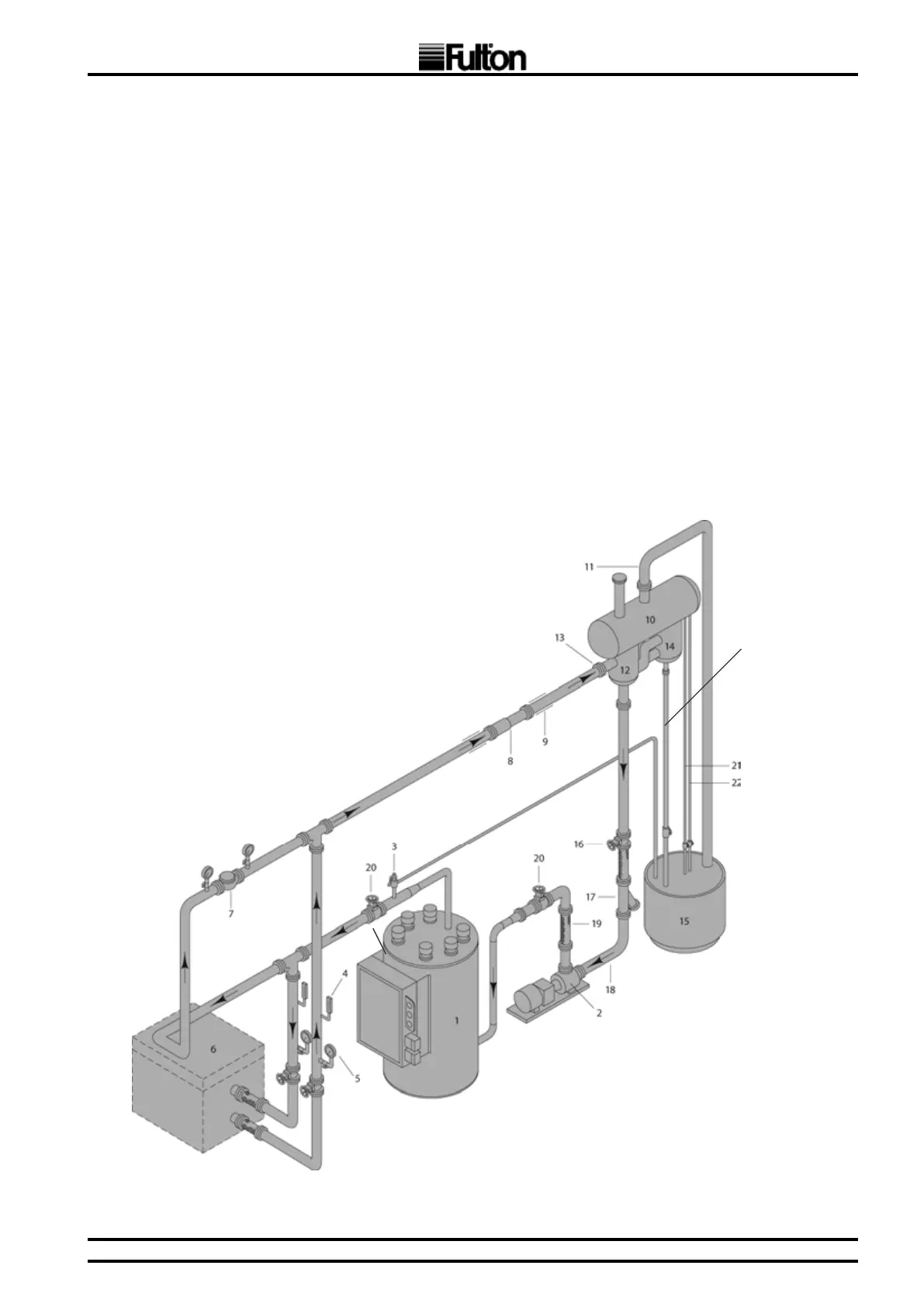

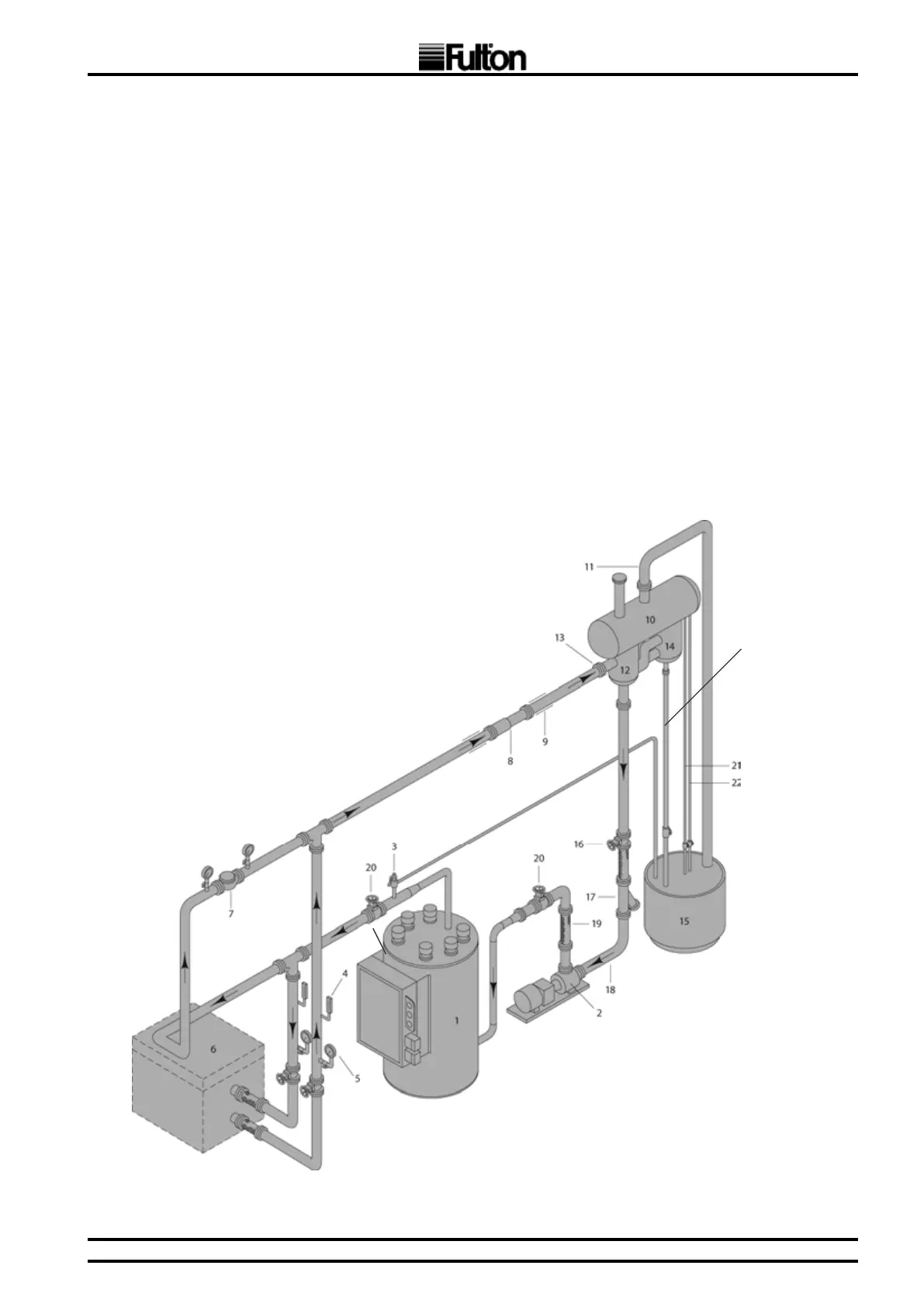

1. Thermal Fluid Heater

2. Thermal Fluid Circulating Pump

3. Safety Relief Valve

4. Thermometer

5. Pressure Gauge

6. Thermal Fluid Heated Equipment

7. Bypass Valve to maintain full flow to heater

8. Expansion Joints as required

9. Anchor and Pipe Guides as required

10. Expansion Tank

11. Vent Piping should be full size of expansion tank vent

12. Deaerator Tank

13. Deaerator Tank inlet must be highest point of piping

14. Thermal Buffer Tank

15. Catch Tank for drain of pressure relief valve, cold seal,

expansion tank, and vent. Locate in safe area.

16. Gate Valve

17. Strainer

18. ¾” System Fill Connection

19. Flexible Connection as necessary

20. Isolating Valve as necessary

21. Manual Low Level Test Line

22. Manual High Level Test Line

23. Buffer Drain

Full pump design flow must be maintained at all

times thru the main piping loop. Low flow will

seriously damage heater.

Note: Manifold configuration for illustration only.

See drawing appropriate to particular model.

j) Ensure that all bolts are tightened evenly and to the torque recommended values provided

by the gasket manufacturer.

k) High point bleeds are to be installed at all high points in the system piping. DN15 x 300 mm

nipples welded in the top of the piping with ball valves & plugs attached are to be used.

l) It will save a considerable amount of time during the cold ltration if the thermal system

piping is cleaned prior to assembly.

m) The mill scale (the results of oxidation) on the inside of the piping as well as construction

debris can foul the oil and cause the need for the lters to be cleaned more than need be.

This can range from simply using a rag to ordering pickled pipe. (“Pickling” is a process

where the piping is rst soaked in an acid bath, then soaked in a neutralizing bath, then

given a protective oil coating.)

n) All pipes should be installed with a pitch to facilitate draining and venting.

Inspect the system daily for leaking joints. Shut the system down and tighten any leaking anges or

connections immediately.

Full pump design ow must be maintained at all times

through the main piping loop. Low ow will seriously

damage the heater.

Loading...

Loading...