FT-C Vertical Electric Thermal Fluid Heater Manual 12 2013 ISSUE 1

The following schedule is the advice of Fulton Ltd. The frequency of tests and checks may vary

according to site risk assessment and/or specic requirements of the country/territory that the boiler

is installed in. Failure to maintain the heater adequately may void the Fulton warranty.

Maintenance on gas related parts of a boiler must be carried out by competent, trained personnel

vwho have the necessary equipment to check combustion. If any fault is found during these

operations, contact your Fulton representative.

1. Complete the log sheet attached at the end of this section at least once per day as a minimum.

It is recommended that the log sheet be lled out twice per shift of operation. The log sheet is

available from the Fulton service department and at the end of this manual.

2. Make a visual inspection of the entire system for leaks. Make repairs as soon as possible.

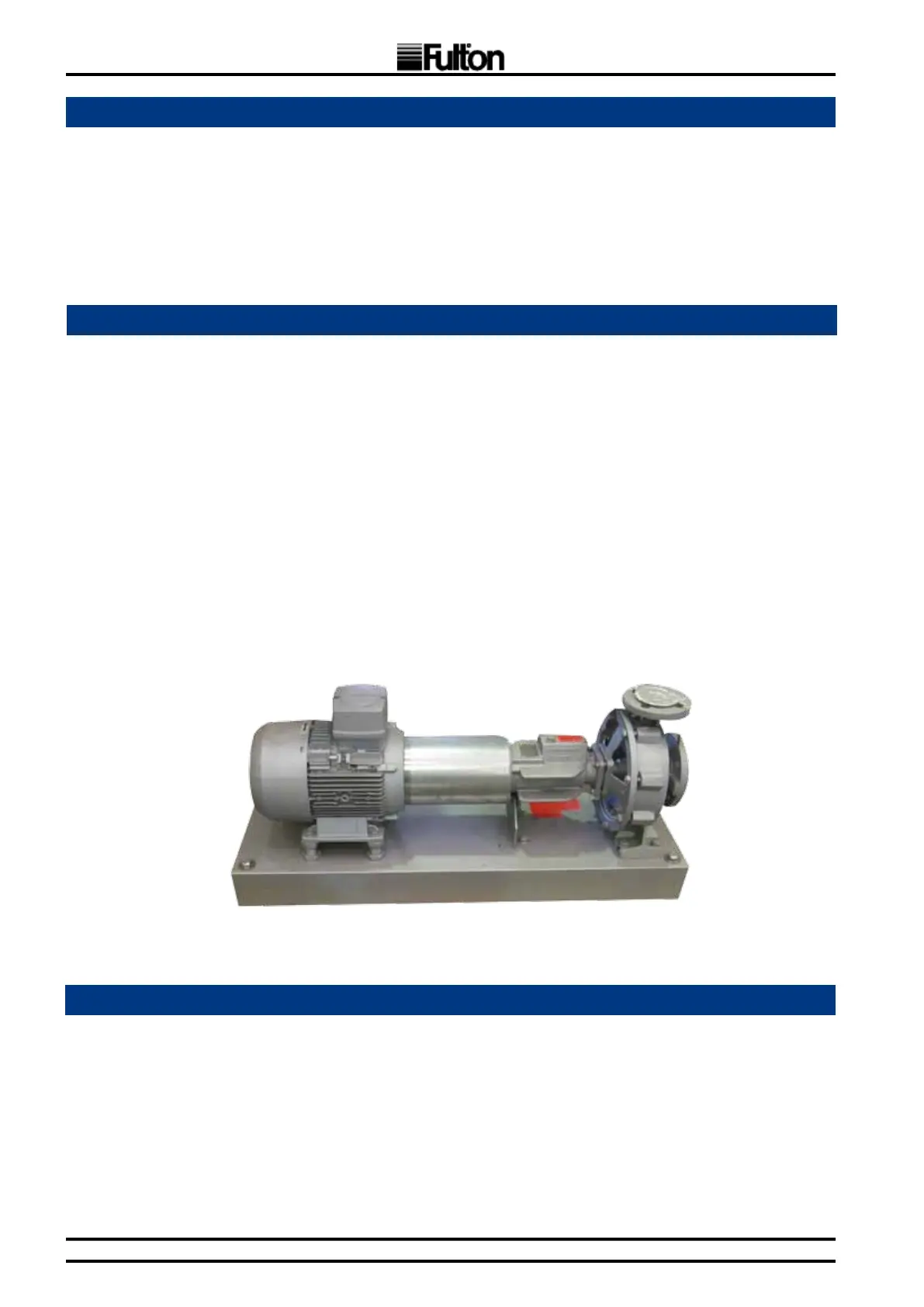

3. In systems utilising a water cooled thermal uid circulating pump, check the level of lubricating

oil in the self-levelling reservoir and check the cooling water circulation loop for proper

operation.

4. Note any failures on the ame programmer noting fault number, fault code, fault annunciation,

fault hour, fault cycle and fault time.

5. Check the exhaust for the presence of smoke. If smoke is present, contact your local Fulton

Representative.

1) Check inlet gas pressure at the beginning of the gas train. This should be accomplished by the

installation of an appropriately scaled gauge.

2) Check manifold gas pressure at high and low ! re and compare to Thermal Combustion Check

list lled out by start up technician. This should be accomplished by the installation of an

appropriately scaled gauge. Readings should be with .02” w.c. of Thermal Combustion

Checklist.

Loading...

Loading...