2 INSTALLATION

© Fulton 2018

2-22

VSRT_IOM_2018-1213

8. High point bleeds/air vents are to be installed at

all high points in the system piping.

9. All pipes should be installed with a pitch to

facilitate draining and venting.

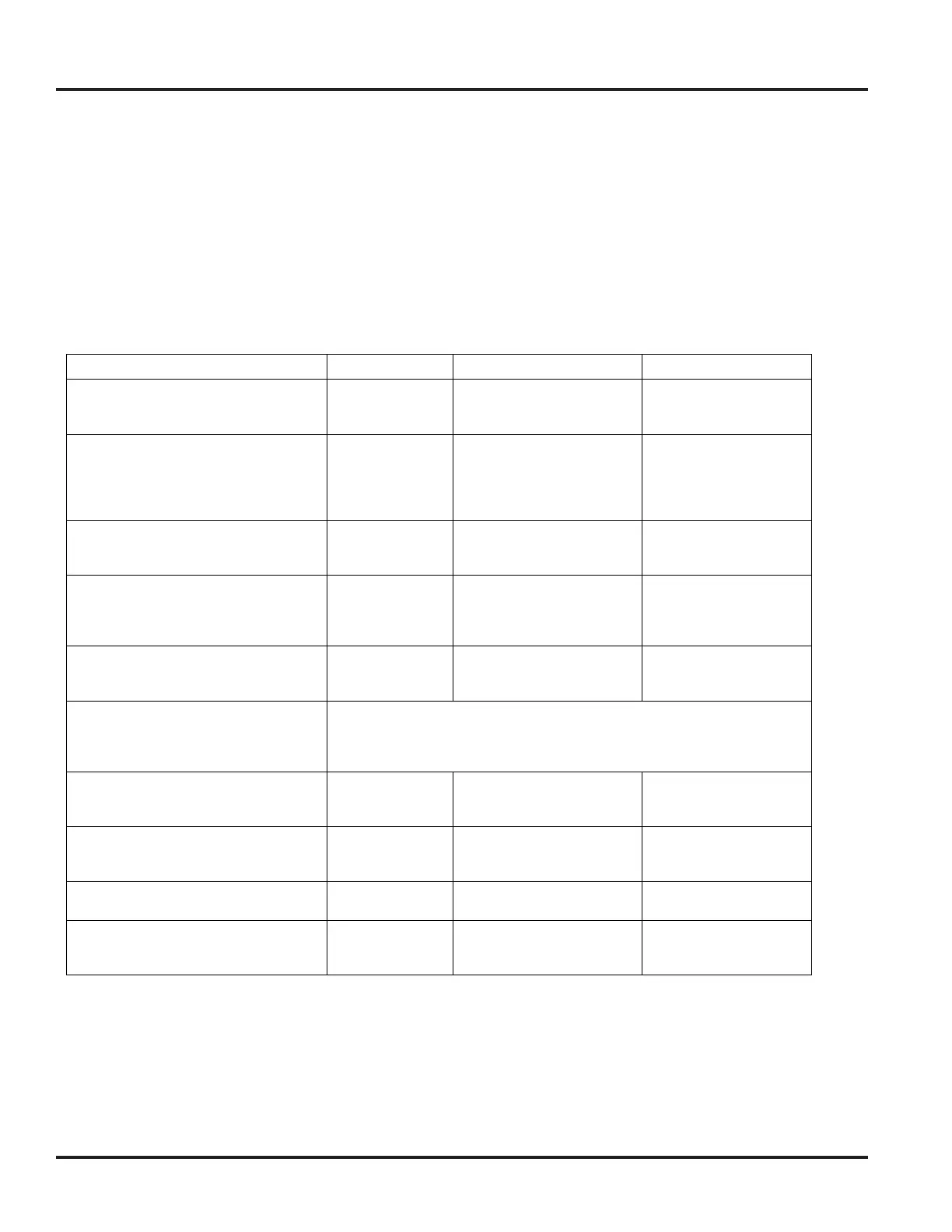

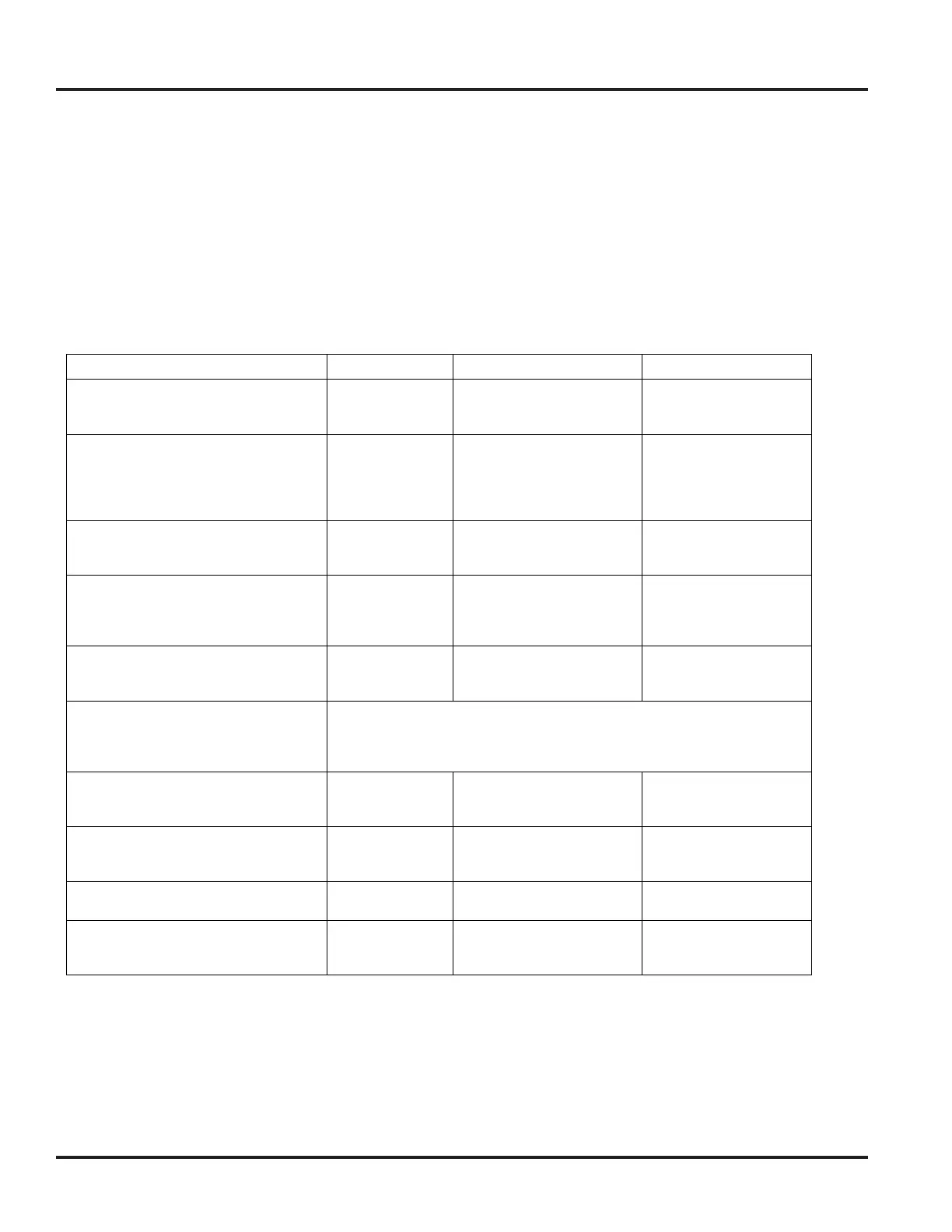

Skid Packaged Steam System Piping Specication

(Boilers with a maximum operating pressure of 125 psig, 150 psig max. trim pressure)

Service Pipe Fittings Joints

Blowo Sch 80 SA 53A or B

or SA 106B

≤ 2.5” Forged Steel CL3000

≥3” SA 234/SA 105

≤ 2.5” Threaded

≥3” welded/anged 300#

Water bottle nipples

Note: downstream of the water bottle

drain valve to follow surface blowdown

piping requirements

Sch. 40 SA 53A or B

or SA 106B

malleable iron CL 150 threaded

Surface Blowdown Piping Sch 80 SA 53A or B

or SA 106B

Forged Steel CL 3000 Threaded

Condensate (i.e., any piping that may

come in contact with the condensate that

is not deaerated – water piping).

Sch 80 SA 53A or B

or SA 106B

≤ 2.5” Forged Steel CL3000

≥3” SA 234/SA 105

≤ 2.5” Threaded

≥3” welded/anged 150#

Feedwater – between the pump and the

boiler/steampac++

Sch 80 SA 53A or B

or SA 106B

≤ 2.5” malleable iron CL150

≥3” SA 234/SA 105

≤ 2.5” Threaded

≥3” welded/anged 150#

Pump Recirculation orice piping A length of straight pipe a minimum of 20 pipe diameters directly downstream

of the orice shall be sch. 80 Stainless Steel pipe and the rst elbow shall be an

extra heavy Stainless Steel elbow. Remaining piping to follow the requirements

for Deaerator heated piping above.

Steam Headers/Deaerator steam piping to

125 psig incoming steam pressure+++

Sch 80 SA 53A or B

or SA 106B

≤ 2.5” malleable iron CL 150

≥3” SA 234/SA 105

≤ 2.5” Threaded

≥3” welded/anged 150#

Overow/Drain piping (water) including

DA liquid drainer piping

Sch 40 SA 53A or B

or SA 106B

≤ 2.5” malleable iron CL 150

≥3” SA 234/SA 105

≤ 2.5” Threaded

≥3” welded/anged 150#

Blowdown tank drain and outlet piping Sch 40 SA 53A or B

or SA 106B

malleable iron CL 150 Threaded

100% fresh cold water make up (including:

DA tanks, water softener, etc)

Type L copper

Note: Piping within the boiler’s ASME code piping boundary supersedes the information in this table.

++ If there is no preheat in the feedwater tank, feed water piping between the feedwater tank and the boiler should be sch 80, SA 106B.

+++ Welded/anged pipe (3” and greater) may be sch. 40.

Table 6 - Sample Piping Specication

Loading...

Loading...