OPERATION 3

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

3-7

VSRT_IOM_2018-1213

Operating Controls

The following specications, data, equipment and

operating descriptions apply to typical Vertical

Boiler units. These sections are provided for general

information purposes only, and do not necessarily

reect the specic details of individual systems.

At commissioning, the operation of all safeties and

interlocks should be veried. Setpoints of all pressure

and temperature switches as well as the programs for

all programmable controls (pressure controls, pressure

limits, operating controls, servo motors etc.) should

be recorded for future reference. Contact the Fulton

Service Department with any questions regarding the

proper operation, set points and verication procedures

for these controls.

Burner Settings

Burner combustion settings:

Typical O2 for proper combustion is 4.5-6%.

Typical O2 for the ignition position (P0) is 3.5-5%

for reliable light o and ame sensing..

» P0 set point is typically between P1 and P2

on combustion curve.

OTE: Pilot pressure range is to be 2.5” w.c.

to 3.5” w.c.

» Lower O settings can reduce burner mesh

life.

» Higher O settings will reduce the overall

eciency of the burner.

Boiler pressure controller is Yokogawa UT-32A.

Burner combustion adjustment guidelines:

Up Down

Fan Speed Adjustment More O, More Input Less O, Less Input

Gas Servo Adjustment More Input, Less O Less Input, More O

Air Servo Adjustment More O, Less Input Less O, More Input

SKP-25 Adjustment More Input, Less O Less Input, More O

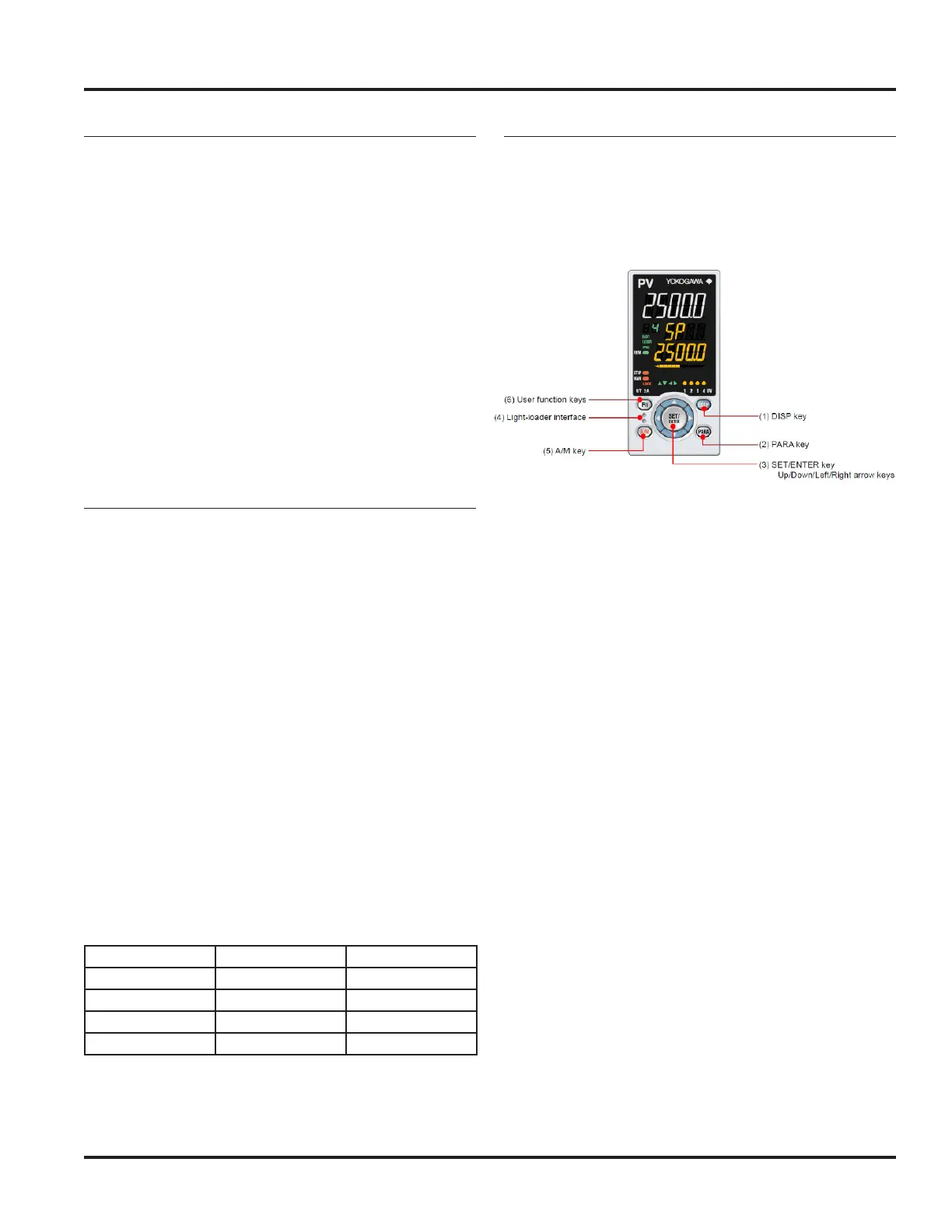

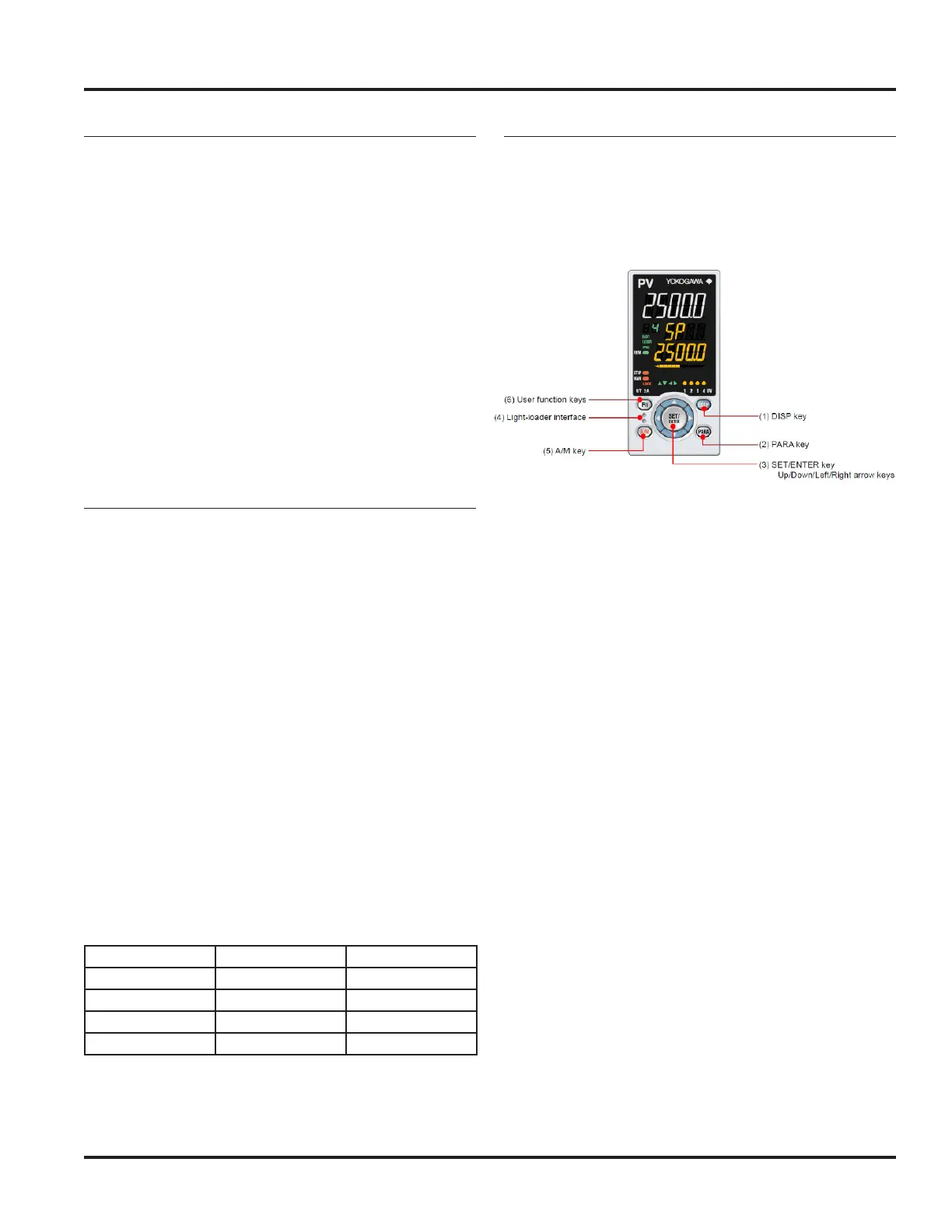

Pressure Modulation Controller

ADJUSTMENT OF THE YOKOGAWA UT32A

OPERATING CONTROLLER:

Front panel keys are shown below and explained in the

text that follows.

(1) – DISP key used to switch the Operation Displays.

Press the key in the Menu Display or Parameter

Setting Display to return to the Operation Display.

(2) – PARA key hold down the key for 3 seconds

to move to the Operation Parameter Setting

display. Hold down the key and the left arrow key

simultaneously for 3 seconds to move to the Setup

Parameter Setting Display. Press the DISP key in the

Parameter Setting Display to return to the Menu

Display. Press the SET/ENTER key once to cancel the

parameter setting (set point is blinking)

(3) SET/Enter key press the key in the Menu Display

to the Parameter Setting Display of the Menu. Press

the key in the Parameter Setting Mode to change

the set point.

(4) – Light-loader interface is the communication

interface to the adapter cable when setting and

storing parameters via PC.

(5) – A/M key used to switch between AUTO and

MAN modes.

(6) – Fn user function key dened by user. PID will

display when Fn key is pressed.

Parameter set-point adjustments are shown in the gure

on the next page and explained in the text that follows.

Loading...

Loading...