3 OPERATION

© Fulton 2018

3-4

VSRT_IOM_2018-1213

2. Once purge is completed, the control will drive

the blower speed, the air buttery and the gas

buttery to the ignition position.

3. Once all devices are stable, the control will

energize the ignition transformer, followed by

opening the pilot gas valve, igniting the pilot

ame.

4. Once pilot ame is established, the ignition spark

will de-energize, and the pilot ame must remain

proven by the scanner for a short safety time.

5. The main gas valve will now be energized,

supplying fuel to the burner, and lighting the

main ame.

6. The pilot valve turns o, and the main ame

must remain proven by the scanner for a second

short safety time.

7. The control now releases to modulation. The

ring rate will now be dictated by the load on the

system, as measured by the pressure controller.

8. The burner output will vary from high re down

to low re continuously in order to match load.

9. Once the system load has been satised (steam

pressure in the system exceed setpoint) the

burner will initiate it’s shutdown sequence.

10. If possible in time allotted (and if the system

is set-up and sized properly), the burner will

modulate to low re before shutting down.

Regardless of ring rate, the shutdown begins

with the main gas valve de-energizing, stopping

fuel ow to the burner.

11. The control will then drive air damper and the

blower to their specied post-purge position,

after which it will purge combustion gasses from

the unit for 15 seconds.

12. The control will then de-energize the blower

motor and drive all gas and air dampers to their

closed position

13. The burner will remain in the o state until the

system steam pressure falls below setpoint for

the burner to turn back on.

Flame Programmers

FLAME SAFEGUARD CONTROL

This is the main control in the panel box. The

programmer in conjunction with a sensing device

(UV scanner) supervises the ame ignition sequence,

proves that the ame is satisfactory and monitors the

established ame. Should any fault occur, either during

the ignition sequence or during normal operation, the

programmer will immediately go to “lock-out” and the

burner will shut down.

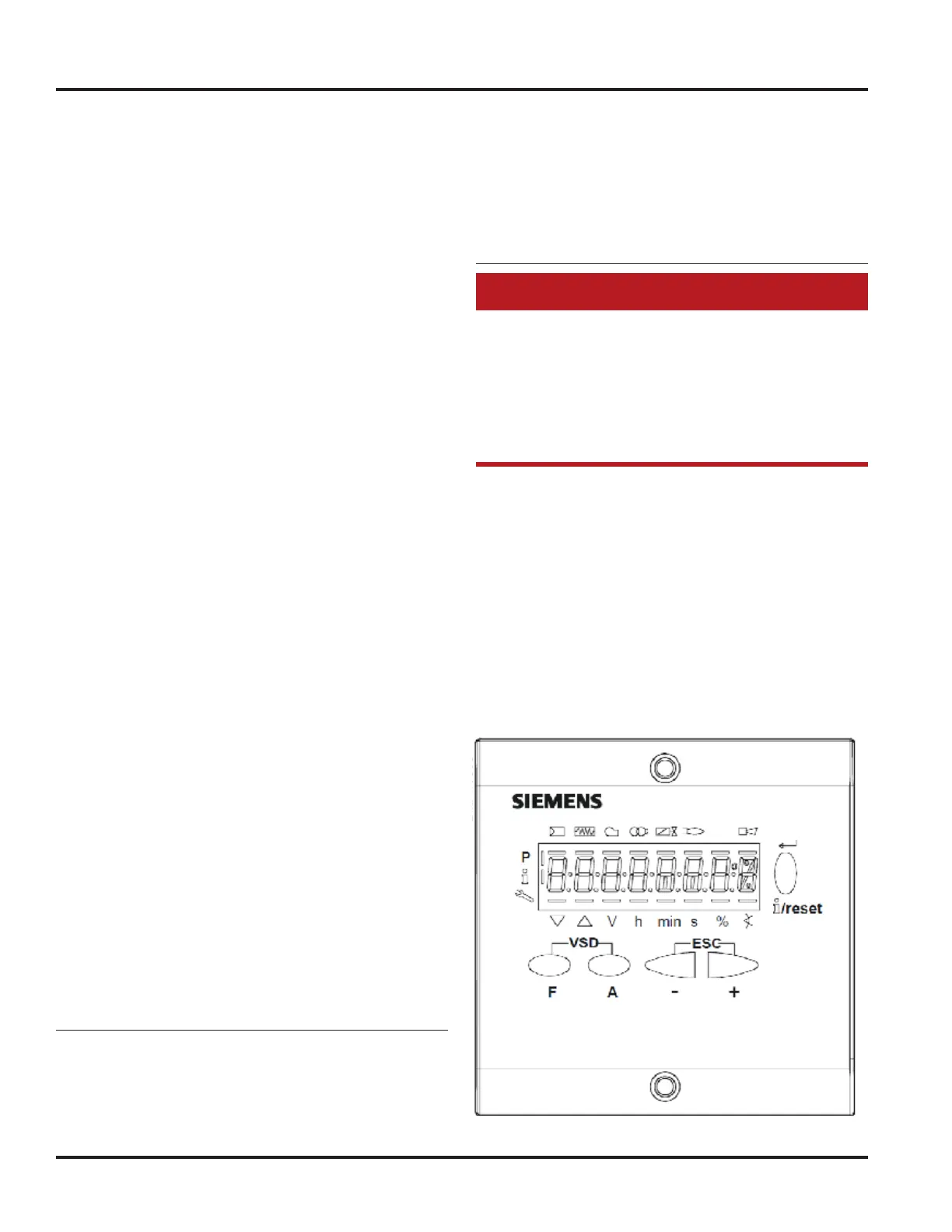

Siemens Linkageless Modulation

! WARNING

This information is for reference purposes only.

Fulton Companies is not responsible for this product,

including (but not limited to) its accuracy, reliability,

and safety. No Fulton document should substitute

for full review of documentation available from the

product manufacturer.

The Siemens LMV3 system is a fully packaged burner

management system, linkageless control and rst

out annunciator. When operating the Siemens LMV3

systems, all changes are made through the Siemens

AZL display. The left and right arrow keys are used for

scrolling through the menu and changing controller

parameters. “Enter” accepts the menu and parameter

changes. It is possible to return to the main menu at any

time by repeatedly pressing “Escape” (pressing the “+”

and “-“ keys at the same time). When running the boiler,

the status of the burner is to be monitored with the

Siemens AZL display (see below).

Loading...

Loading...