MAINTENANCE & TROUBLESHOOTING 4

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

4-3

VSRT_IOM_2018-1213

Recommended Daily Maintenance

Schedule

! WARNING

Check daily that the boiler area is free and clear of any

combustible materials , including ammable vapors

and liquids.

! CAUTION

Observe operating temperature and general conditions.

Make sure that the ow of combustion and ventilating

air to the boiler is not obstructed.

The following procedures should be carried out daily

as recommended maintenance. They are designed to

prevent the buildup of scale, silt, or sludge in the bottom

of the boiler and in the pipes leading to the water gauge.

In addition to these procedures, the advice of a water

treatment supplier should be sought and followed. An

ASME Section VIII blowdown tank must be provided.

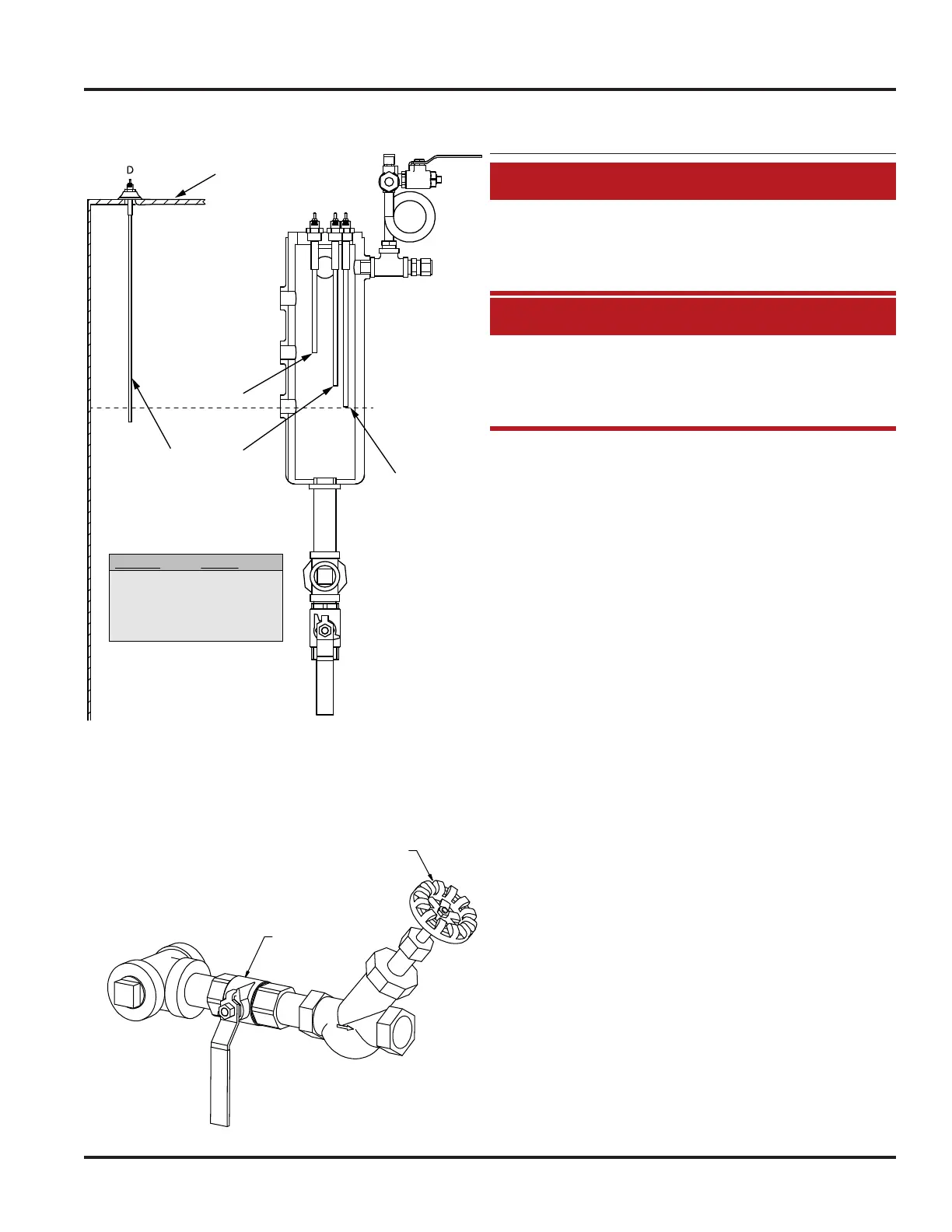

1. Blow down the boiler each morning by starting the

boiler and generating not more than 10 PSI (.7 kg/

cm2) of steam. Turn on cooling water to blowdown

tank, if equipped, then open the boiler blow o

valve for approximately 10 seconds, then close

valve. See Figure 19. Be sure that the slow opening

valve (Y-Valve) is adjusted properly. The slow

opening valve is to be adjusted so that only 1-2”

of water empty from the boiler sight glass during

the 4-10 second bottom blowdown. During each

blowdown, there should be 1-2” of level drop in the

sight glass. If a manual method of cooling water is

used, be sure to shut o the cooling water supply.

If there are two bottom blowdown connections on

the boiler, both should be blown down daily.

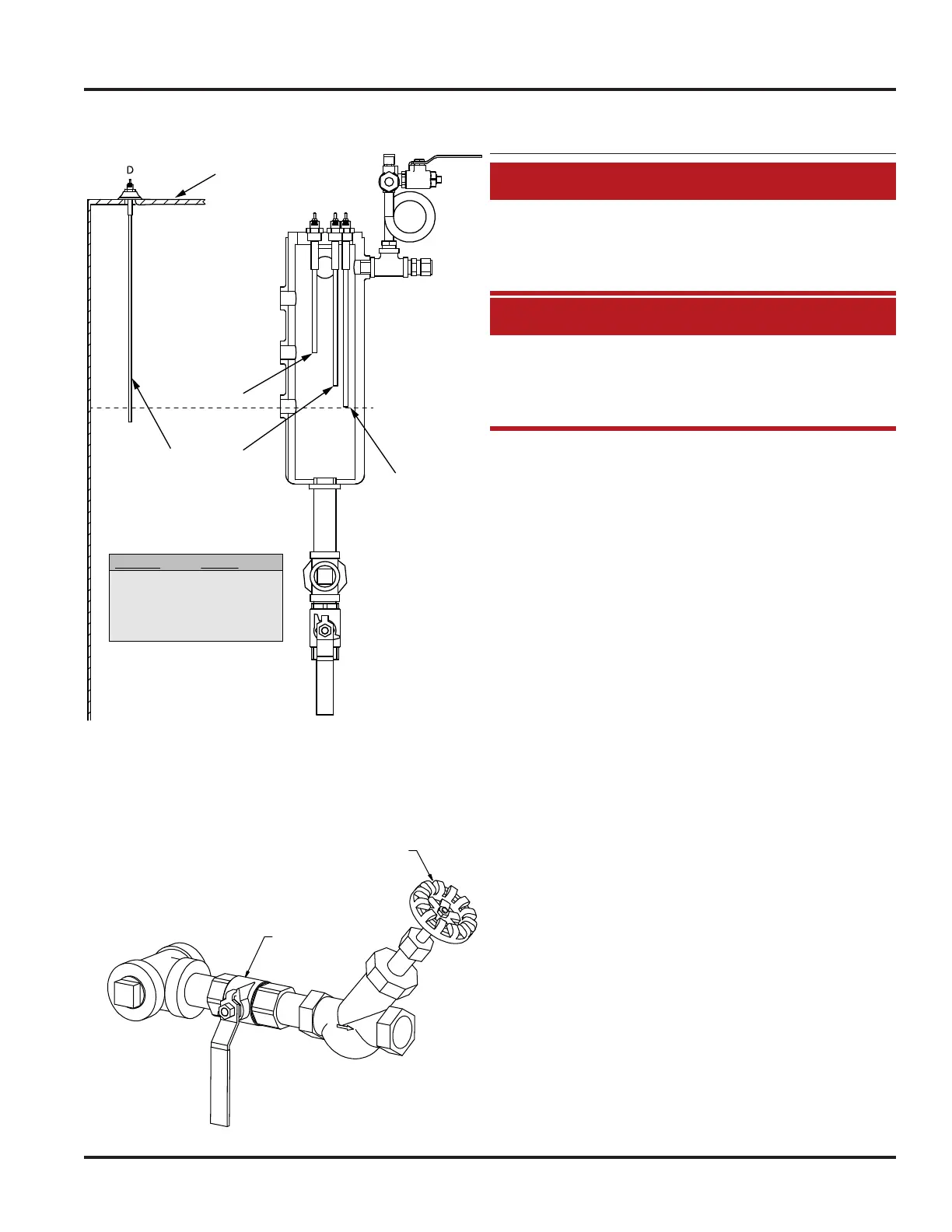

2. Blow down water column each morning when

boiler is at 10 PSI (.7 kg/cm2) by opening the water

column and the water gauge blowo valves (see

Figure 20) for approximately ve seconds, then

close the valves. On boilers with oat type level

devices, refer to the water column cut sheet for

proper blowdown technique. Any water column on

the system should be blown down daily following

the above procedure.

3. If the feed water is being treated by chemical

A B C

PRIMARY

LOW WATER

CUTOFF

PUMP OFF

PUMP ON

AUX LOW

WATER

CUTOFF

BOILER SHELL

BOILER WATER COLUMN

Length Part#

A: 7¼" 2-20-000010

B: 9¼" 2-20-000011

C: 10½" 2-20-000106

D: 19" 2-20-000290

SIGHT GLASS

BLOWDOWN

VALVE

WATER COLUMN

BLOWDOWN

VALVE

TOP OF BOILER

QUICK OPENING VALVE

A B C

PRIMARY

LOW WATER

CUTOFF

PUMP OFF

PUMP ON

SLOW OPENING VALVE

AUX LOW

WATER

CUTOFF

BOILER SHELL

BOILER WATER COLUMN

Length Part#

A: 7¼" 2-20-000010

B: 9¼" 2-20-000011

C: 10½" 2-20-000106

D: 19" 2-20-000290

SIGHT GLASS

BLOWDOWN

VALVE

WATER COLUMN

BLOWDOWN

VALVE

TOP OF BOILER

Figure 18 - Probe Lengths

Figure 19 - Bottom Blowdown Valves

Loading...

Loading...