INSTALLATION 2

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

2-27

VSRT_IOM_2018-1213

3. Install the top tting (the tting without the

drain port) into the upper tting on the water

bottle using service rated sealant. Wrench tighten

the tting until it is snug and the glass outlet is

pointing at about 5 o’clock (about 1/8 turn from

its nal downward vertical position).

4. Install the bottom tting (the tting with the

drain port) into the lower tting on the water

bottle. Wrench tighten the tting until it is snug

and the glass outlet is pointing directly upward.

5. Verify that the top and bottom ttings are

threaded into the water bottle tappings the same

amount (horizontally).

6. Remove the glass packing nut, friction washer

and glass packing from the ttings and place

them in the same order on either end of the water

gauge glass. Push both packings about 1in (25.4

mm) from the end of the water gauge glass.

7. Gently insert one end of the water gauge glass

into the top gauge tting. Keeping the glass

inside the tting, gently rotate the top tting

clockwise until it is vertically aligned with the

bottom tting. It is crucial that the gauge

glass valves are aligned both vertically and

horizontally. If not aligned, they may leak.

8. Insert the gauge glass into the bottom tting until

it bottoms out, and then gently raise glass about

1/16 in (1.6 mm). Do not allow glass to remain in

contact with any metal surface.

9. Carefully slide the bottom glass packing down

until the glass packing is touching the lower

gauge tting. Carefully slide the top glass packing

up until the glass packing is touching the upper

gauge tting.

10. Hand tighten both glass packing nuts, then

tighten ½ turn more by wrench. Do not over-

tighten. If any leakage occurs, tighten the packing

nut slightly, no more than a ¼ turn at a time, until

the leak stops.

11. When provided, install the protective guard over

the gauge glass assembly.

12. The gauge glass valves are tted with ball checks.

Make sure that the valves are fully open to ensure

that the ball check will function properly in the

event that the gauge glass breaks.

13. Install drain piping from water bottle and lower

water gauge glass tting to the boiler blow o

piping.

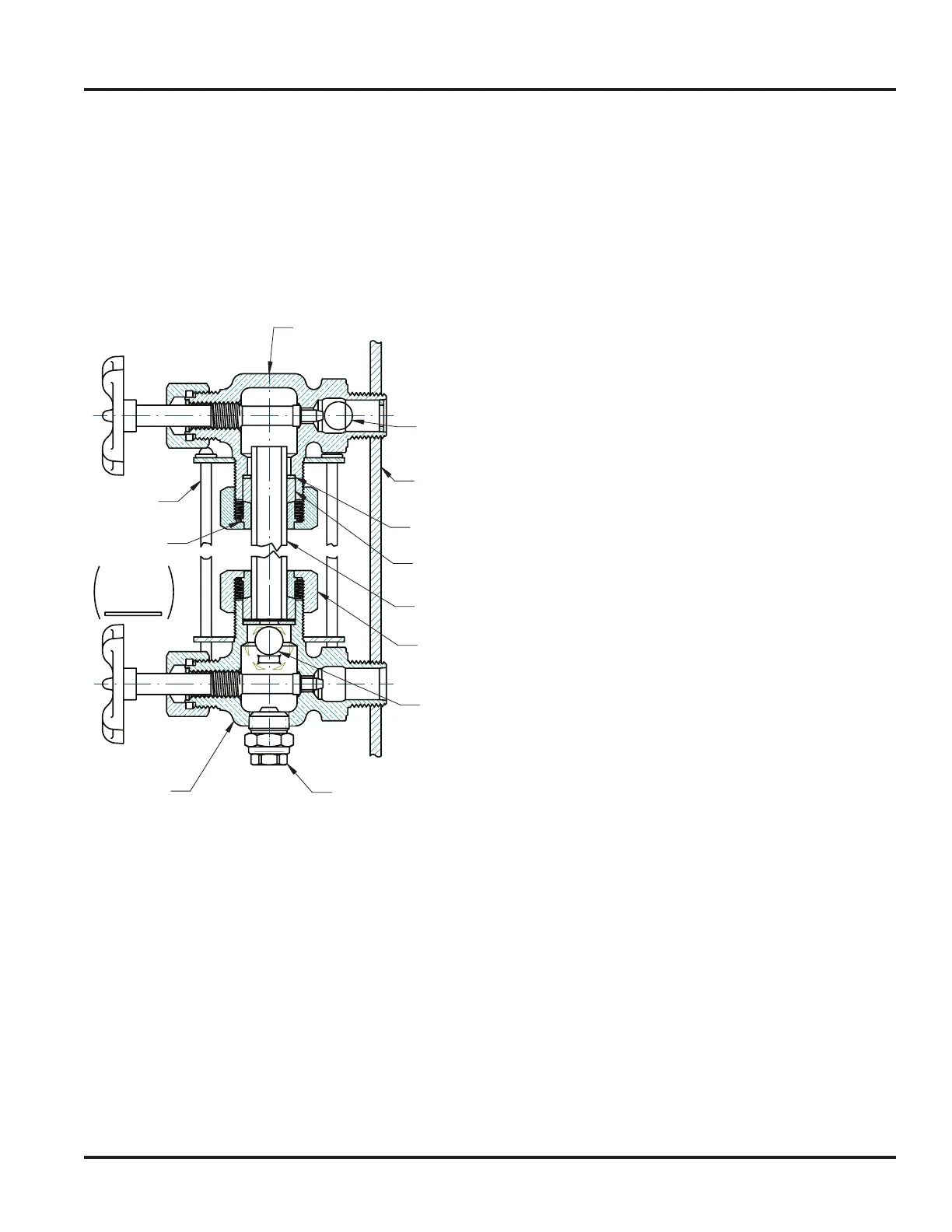

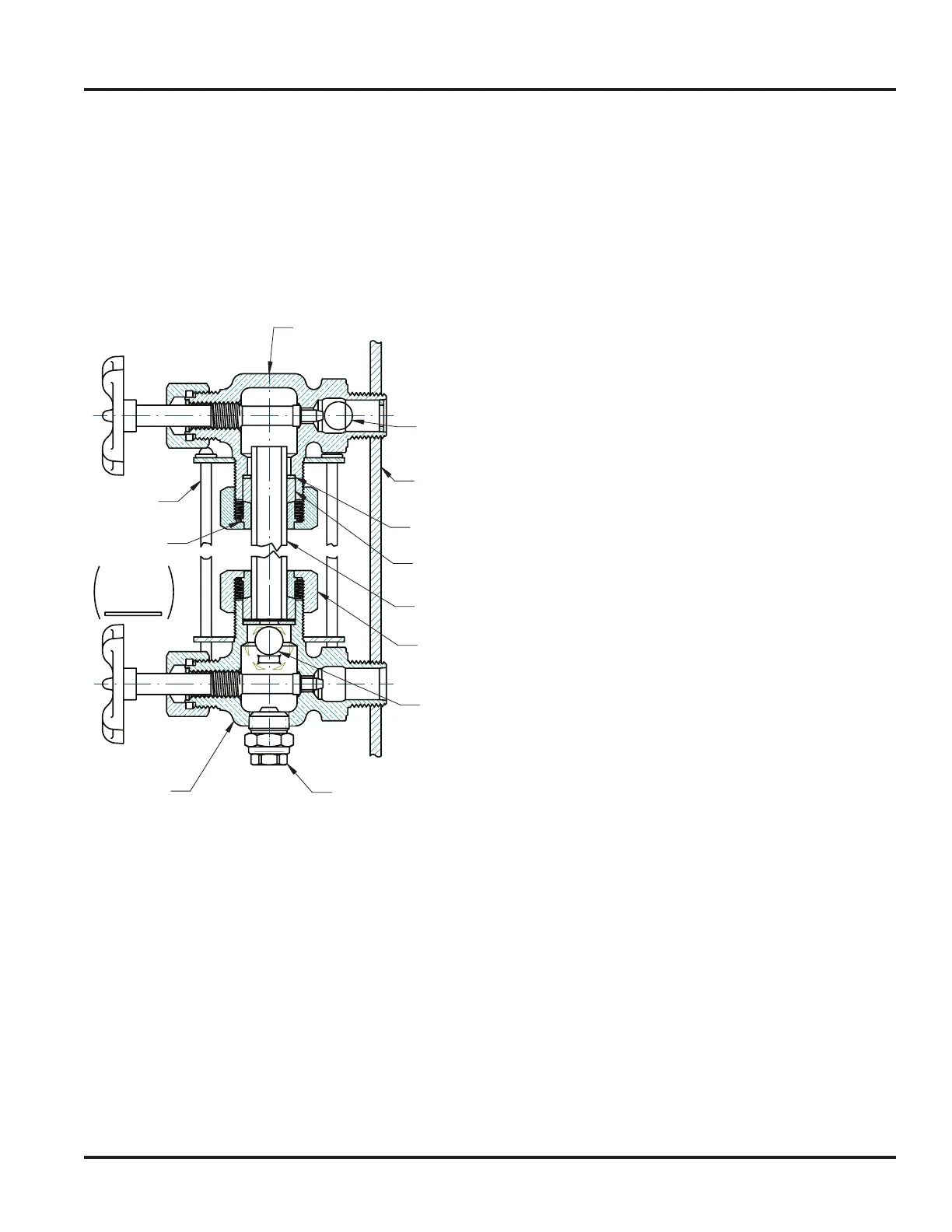

TOP GAUGE FITTING

VESSEL

WALL

GAUGE

GLASS

GLASS

PACKING

NUT

GLASS

PACKING

GUARD

ROD

PACKING

GLAND

(OR

FRICTION

WASHER)

BOTTOM

GAUGE

FITTING

DRAIN

VALVE

BALL

CHECK

VALVE

ASME

AUTOMATI

BALL

CHECK

VALVE

WASHER

Figure 14 - Sight Gauge Glass

Loading...

Loading...