What to do if Software File Mismatch Alert appears on Garmin Autopilot System?

- TTimothy BrownAug 8, 2025

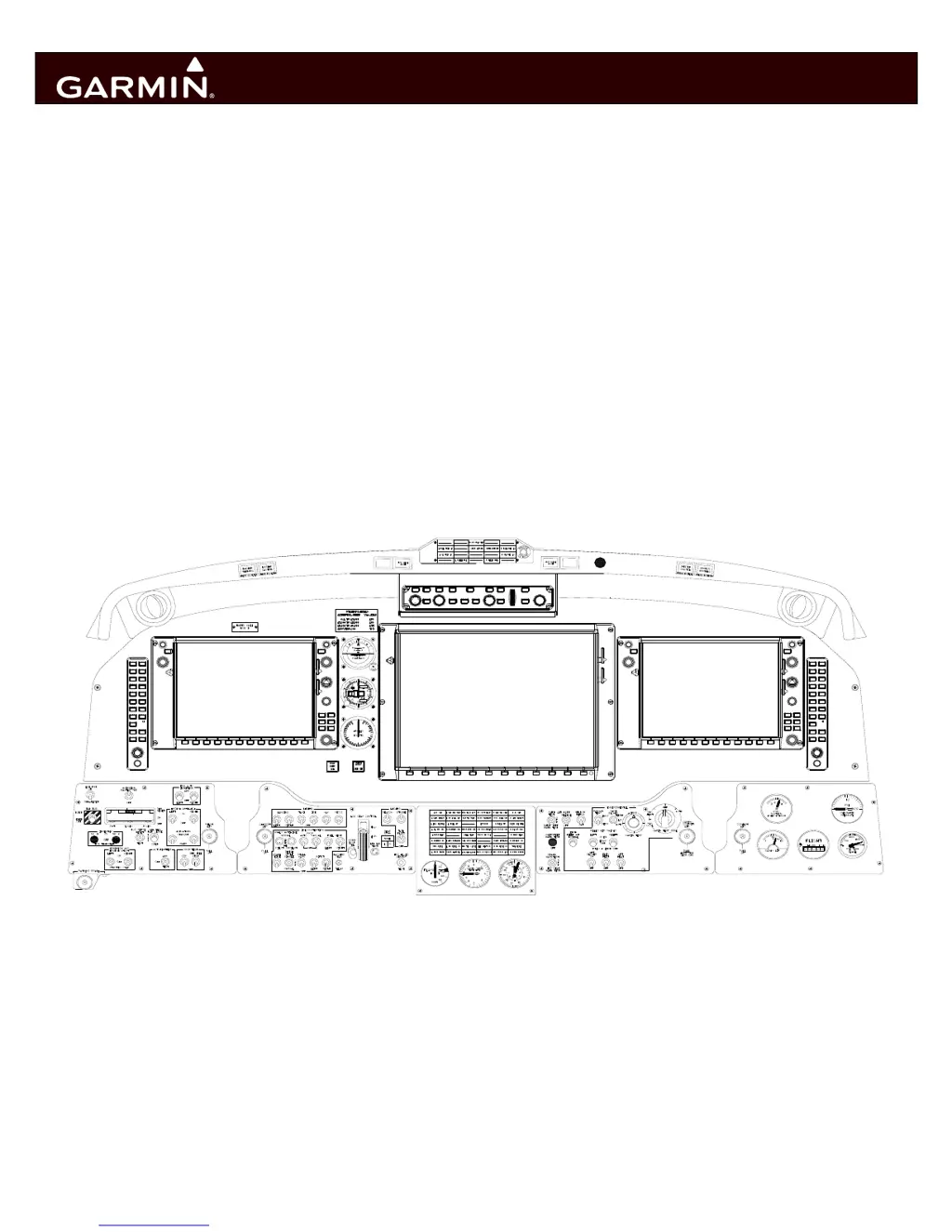

If a Software File Mismatch Alert appears on your Garmin Autopilot System's PFD, verify that the correct software file part number and version were loaded to the LRU. Also, check that the correct Card Loader was used during the load process. If issues persist, try reloading the software to the LRU.