3-50 D30 LINE DISTANCE PROTECTION SYSTEM – INSTRUCTION MANUAL

DIRECT INPUT AND OUTPUT COMMUNICATIONS CHAPTER 3: INSTALLATION

3

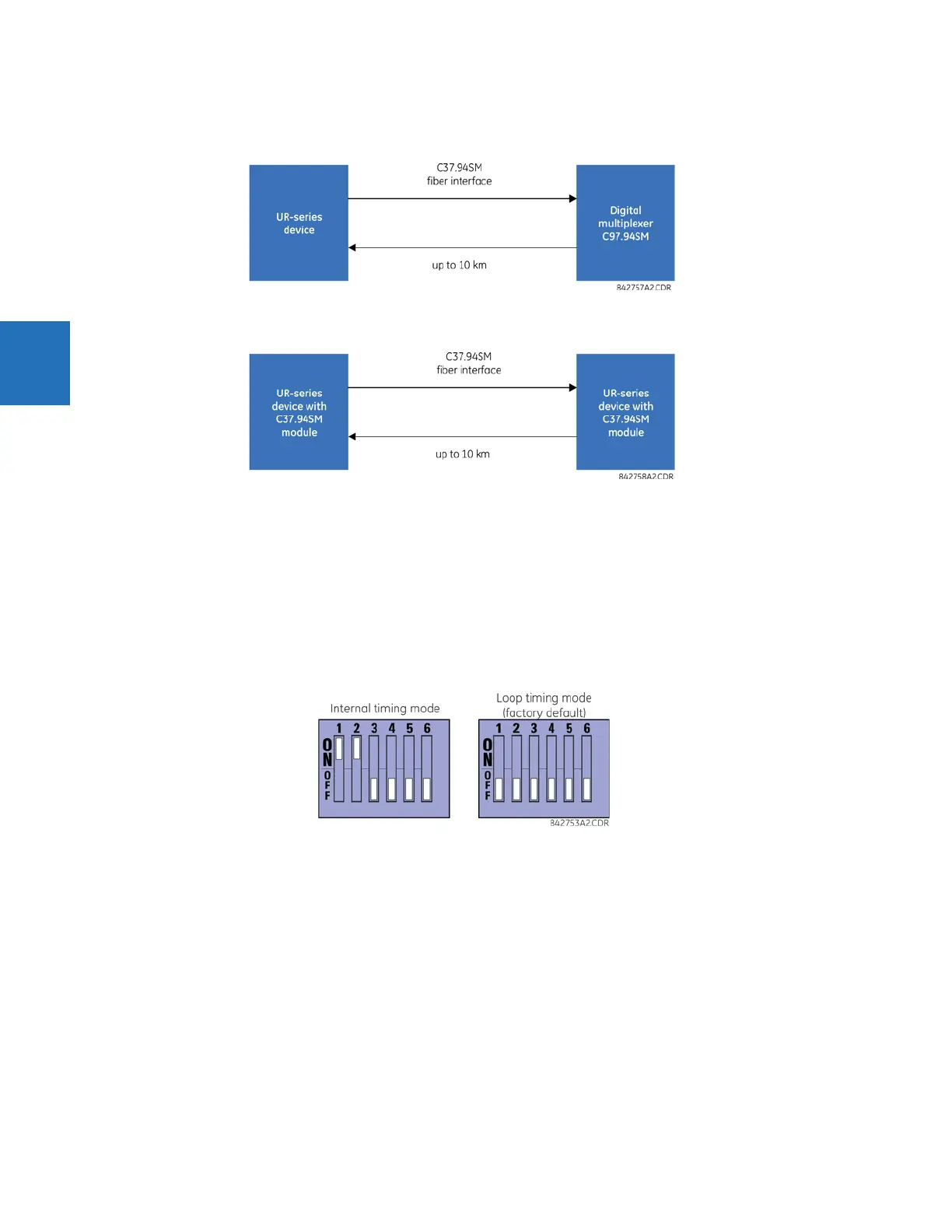

The UR-series C37.94SM communication module can be connected directly to any compliant digital multiplexer that

supports C37.94SM, as shown.

It also can be connected directly to any other UR-series relay with a C37.94SM module, as shown.

In 2008, GE Grid Solutions released revised modules 2A and 2B for C37.94SM communication to enable multi-ended fault

location functionality with firmware 5.60 release and higher. All modules 2A and 2B shipped since the change support this

feature and are fully backward compatible with firmware releases below 5.60. For customers using firmware release 5.60

and higher, the module can be identified with "Rev D" printed on it and is to be used on all ends of D30 communication for

two and three terminal applications. Failure to use it at all ends results in intermittent communication alarms. For

customers using firmware revisions below 5.60, it is not required to match the revision of the modules installed.

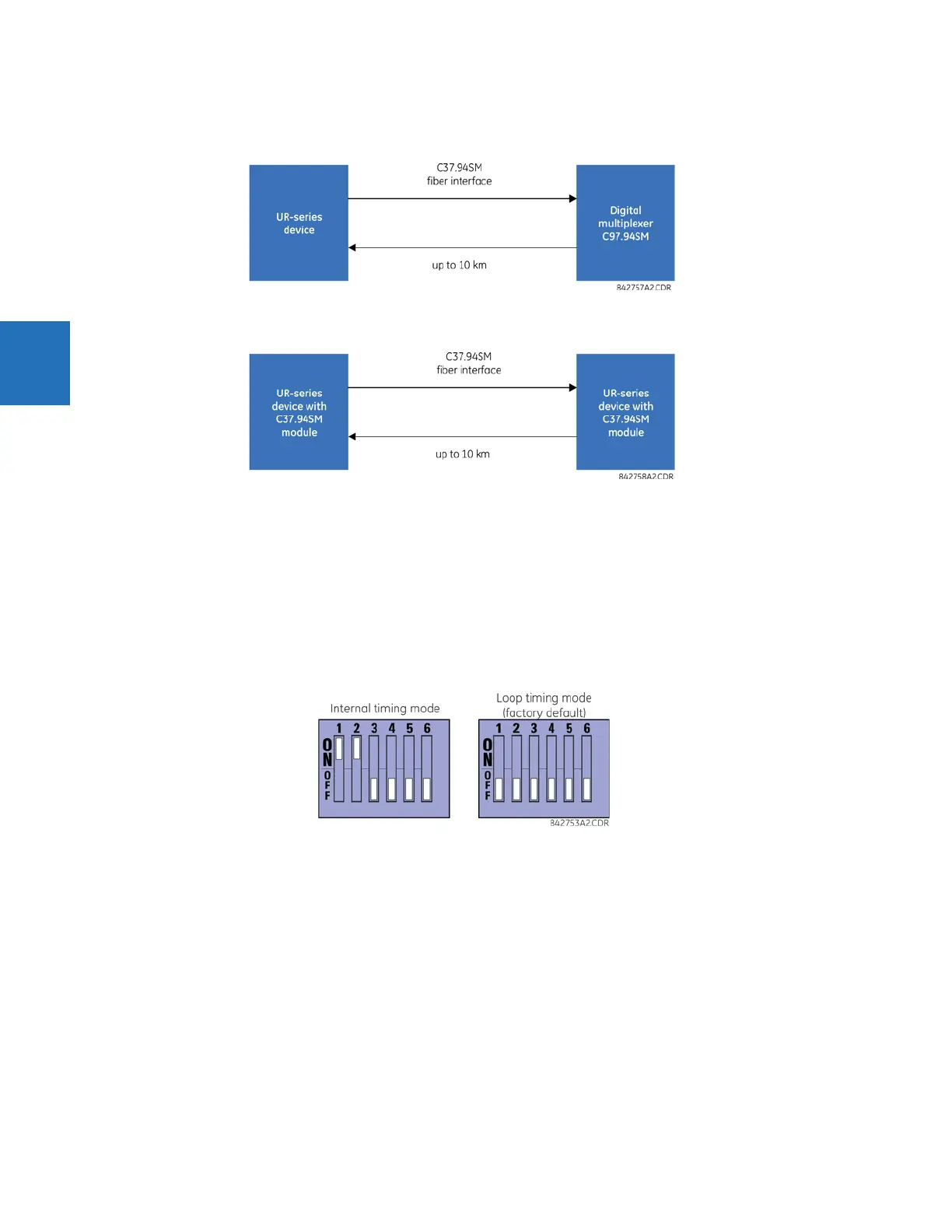

The UR-series C37.94SM module has six switches that are used to set the clock configuration. The following figure shows

the functions of these control switches.

Figure 3-58: Switches

For the internal timing mode, the system clock is generated internally. Therefore, set the timing switch selection to internal

timing for relay 1 and loop timed for relay 2. There must be only one timing source configured.

For the looped timing mode, the system clock is derived from the received line signal. Therefore, set the timing selection to

loop timing mode for connections to higher-order systems.

The C37.94SM communications module cover removal procedure is as follows:

1. With power to the relay off, remove the C37.94SM module (module 2A or 2B) as follows. Record the original location of

the module to help ensure that the same or replacement module is inserted into the correct slot.

2. Simultaneously pull the ejector/inserter clips located at the top and at the bottom of each module in order to release

the module for removal.

3. Remove the module cover screw.

4. Remove the top cover by sliding it towards the rear and then lift it upwards.

5. Set the timing selection switches (channels 1 and 2) to the required timing modes (see description earlier).

Loading...

Loading...