GE Multilin M60 Motor Protection System 6-23

6 ACTUAL VALUES 6.3 METERING

6

6.3.7 TRACKING FREQUENCY

PATH: ACTUAL VALUES METERING TRACKING FREQUENCY

The tracking frequency is displayed here. The frequency is tracked based on the selection of the reference source with the

FREQUENCY AND PHASE REFERENCE setting in the SETTINGS SYSTEM SETUP POWER SYSTEM menu. See the Power

System section of chapter 5 for details.

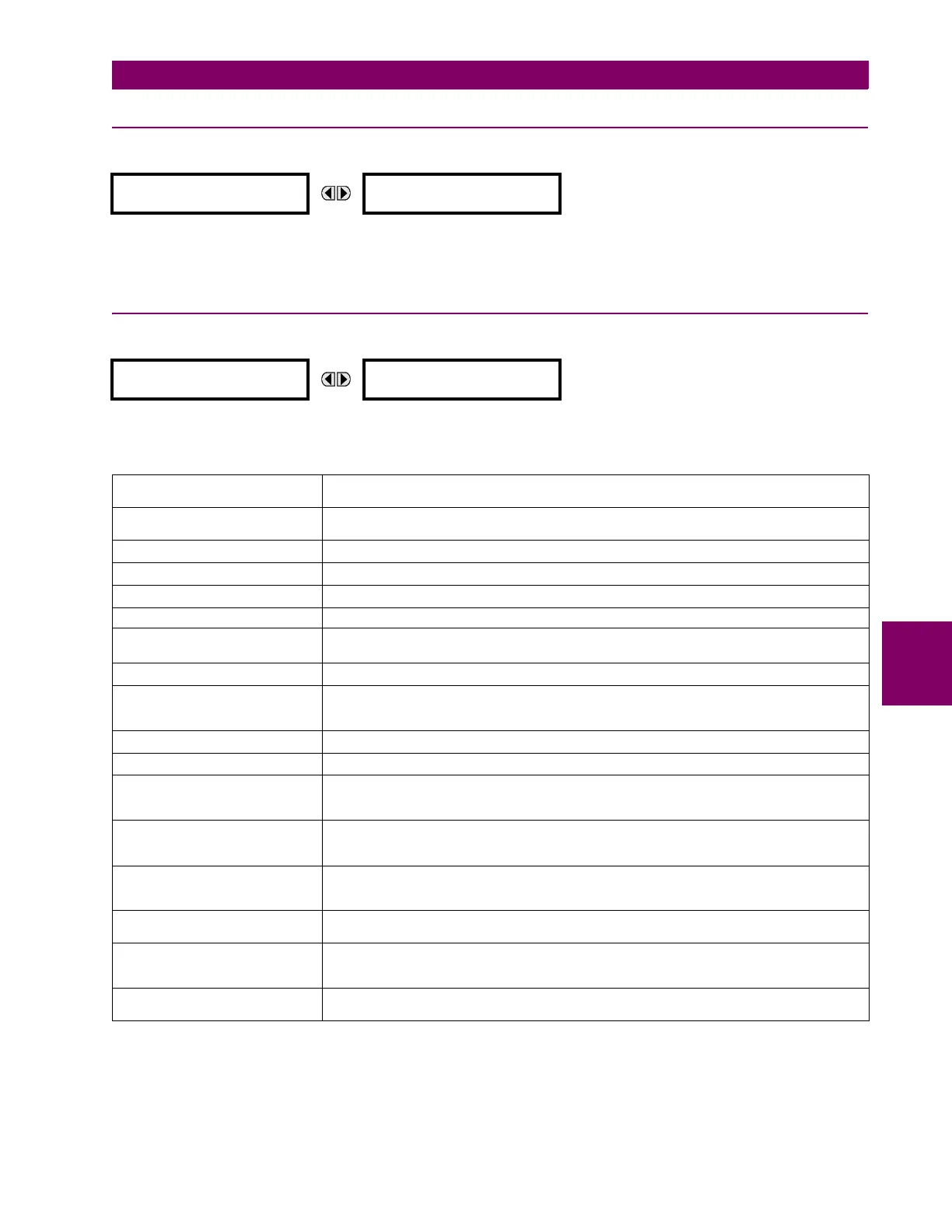

6.3.8 FLEXELEMENTS

PATH: ACTUAL VALUES METERING FLEXELEMENTS FLEXELEMENT 1(16)

The operating signals for the FlexElements are displayed in pu values using the following definitions of the base units.

TRACKING FREQUENCY

TRACKING FREQUENCY:

60.00 Hz

FLEXELEMENT 1

FLEXELEMENT 1

OpSig: 0.000 pu

Table 6–2: FLEXELEMENT BASE UNITS

CURRENT UNBALANCE

(Amp Unbalance)

BASE = 100%

dcmA BASE = maximum value of the

DCMA INPUT MAX setting for the two transducers configured

under the +IN and –IN inputs.

FREQUENCY f

BASE

= 1 Hz

PHASE ANGLE

BASE

= 360 degrees (see the UR angle referencing convention)

POWER FACTOR PF

BASE

= 1.00

RTDs BASE = 100°C

SENSITIVE DIR POWER

(Sns Dir Power)

P

BASE

= maximum value of 3 V

BASE

I

BASE

for the +IN and –IN inputs of the sources

configured for the sensitive power directional element(s).

SOURCE CURRENT I

BASE

= maximum nominal primary RMS value of the +IN and –IN inputs

SOURCE ENERGY

(Positive and Negative Watthours,

Positive and Negative Varhours)

E

BASE

= 10000 MWh or MVAh, respectively

SOURCE POWER P

BASE

= maximum value of V

BASE

I

BASE

for the +IN and –IN inputs

SOURCE VOLTAGE V

BASE

= maximum nominal primary RMS value of the +IN and –IN inputs

STATOR DIFFERENTIAL

CURRENT

(Stator Diff Iar, Ibr, and Icr)

I

BASE

= maximum primary RMS value of the +IN and –IN inputs

(CT primary for source currents, and bus reference primary current for bus differential currents)

STATOR RESTRAINING

CURRENT

(Stator Diff Iad, Ibd, and Icd)

I

BASE

= maximum primary RMS value of the +IN and –IN inputs

(CT primary for source currents, and bus reference primary current for bus differential currents)

THERMAL MODEL

(Model Capacity Used)

(Model Motor Unbalance)

BASE =100%

THERMAL MODEL

(Model Lockout Time)

BASE = 10 minutes

THERMAL MODEL

(Thermal Model Load)

(Biased Motor Load)

BASE = 1.00 pu of FLA

THERMAL MODEL

(Trip Time on Overload)

BASE = 10 seconds

Loading...

Loading...