MAINTENANCE

GE Medical Systems

SENOGRAPHE 800T

REV 6 om 2135575–100

3–4

SECTION 2

PREVENTIVE MAINTENANCE

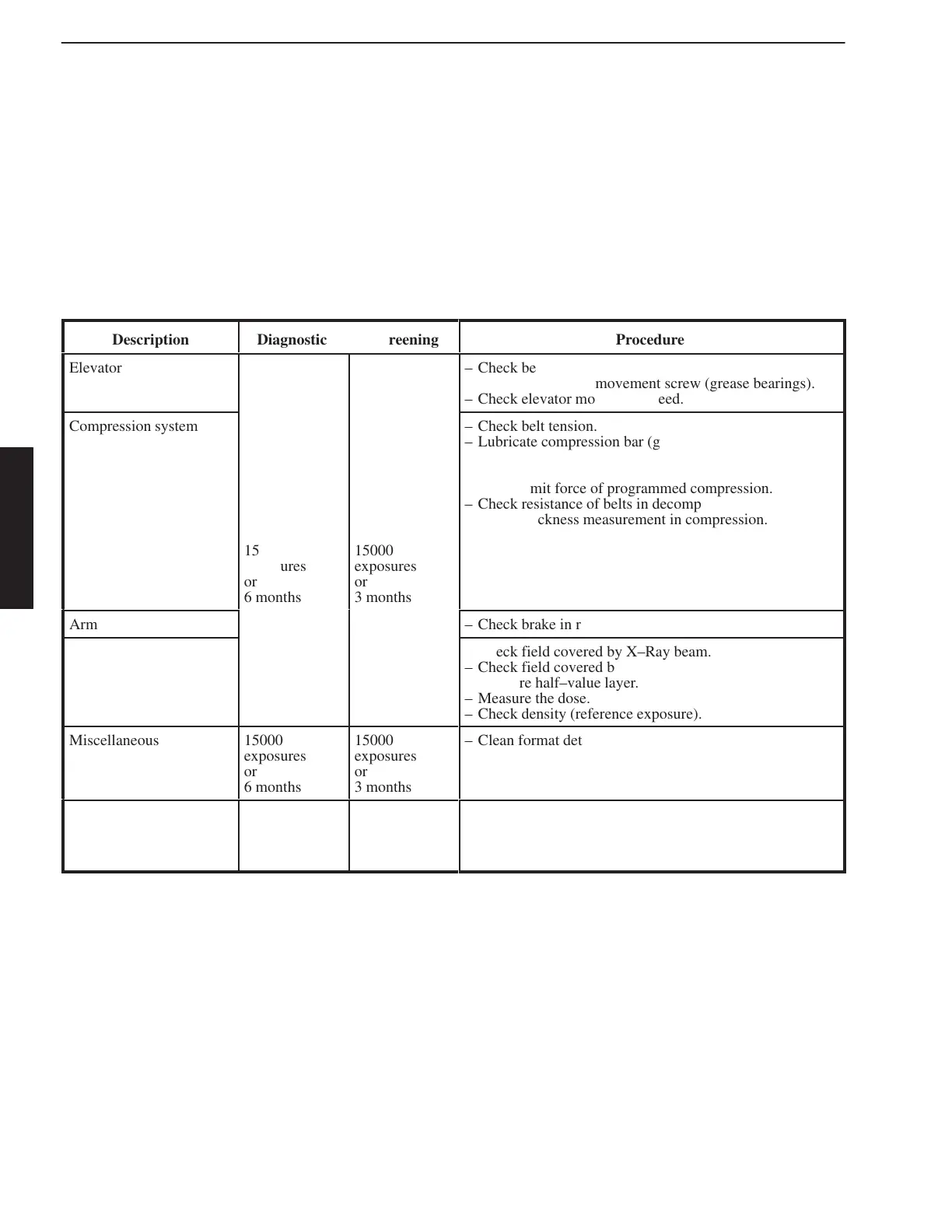

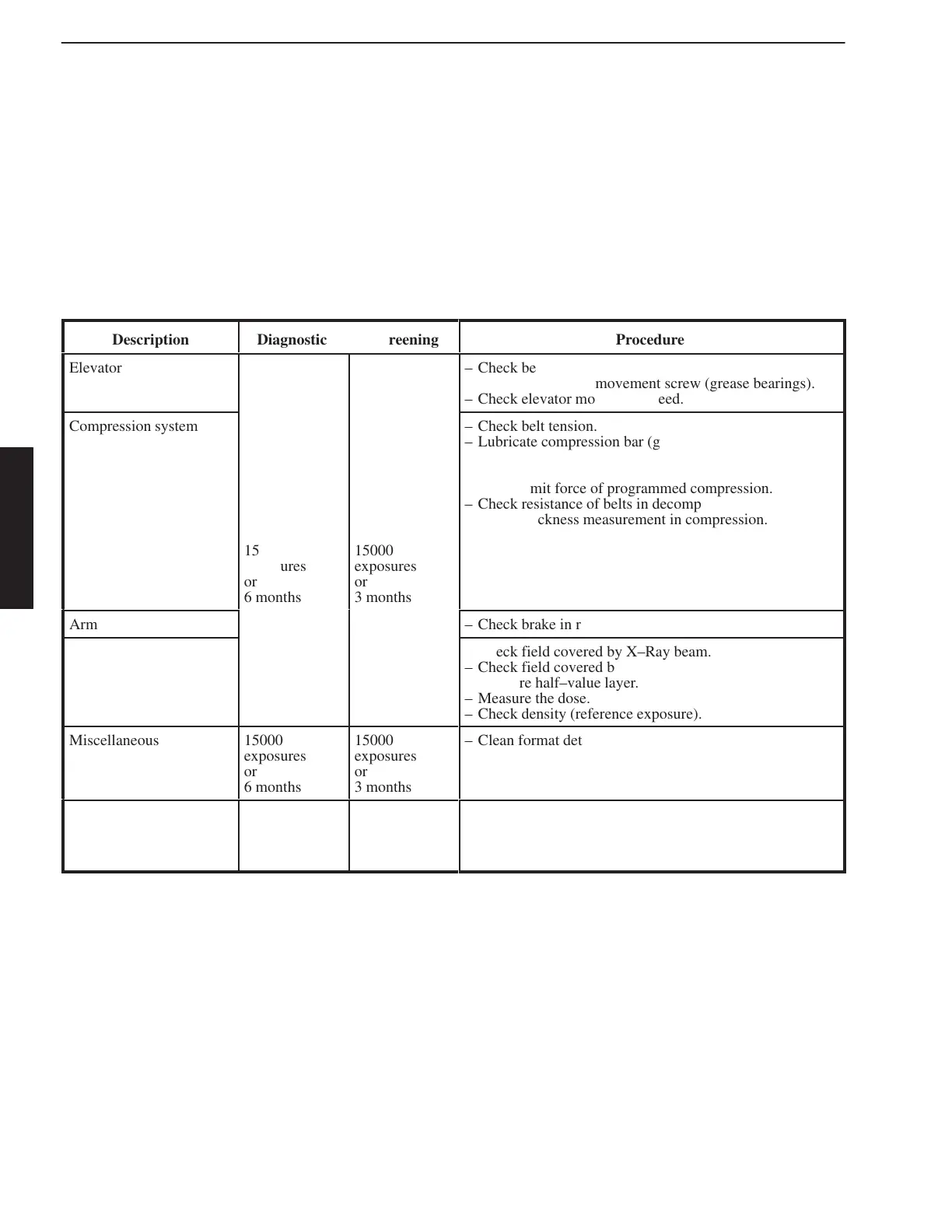

Despite its inherent qualities, the Senographe 800T requires minimum maintenance. A

maintenance program, whose frequency varies according to the type of use of the equipment,

is outlined in the table below.

Maintenance Program

ÁÁÁÁÁÁ

Description

ÁÁÁÁÁÁÁÁÁ

Diagnostic Screening

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

Procedure

ÁÁÁÁÁÁ

Elevator

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Check belt tension.

– Lubricate elevator movement screw (grease bearings).

– Check elevator movement speed.

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Compression system

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

15000

exposures

or

6 months

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

15000

exposures

or

3 months

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Check belt tension.

– Lubricate compression bar (grease bearings).

– Check compression force calibration.

– Check maximum compression force (20 daN).

– Check limit force of programmed compression.

– Check resistance of belts in decompression.

– Check thickness measurement in compression.

Arm

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Check brake in rotation.

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Image quality

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Check field covered by X–Ray beam.

– Check field covered by centering light.

– Measure half–value layer.

– Measure the dose.

– Check density (reference exposure).

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Miscellaneous

ÁÁÁÁ

ÁÁÁÁ

15000

exposures

or

6 months

ÁÁÁÁ

ÁÁÁÁ

15000

exposures

or

3 months

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Clean format detectors.

– Inspect accessories (including grids).

ÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

90000

exposures

or

3 years

ÁÁÁÁ

ÁÁÁÁ

90000

exposures

or

18 months

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

– Replace the two belts of compression system.

– Replace battery in microprocessor board.

Loading...

Loading...