Printed in U.S.A 67 918215/CP0407

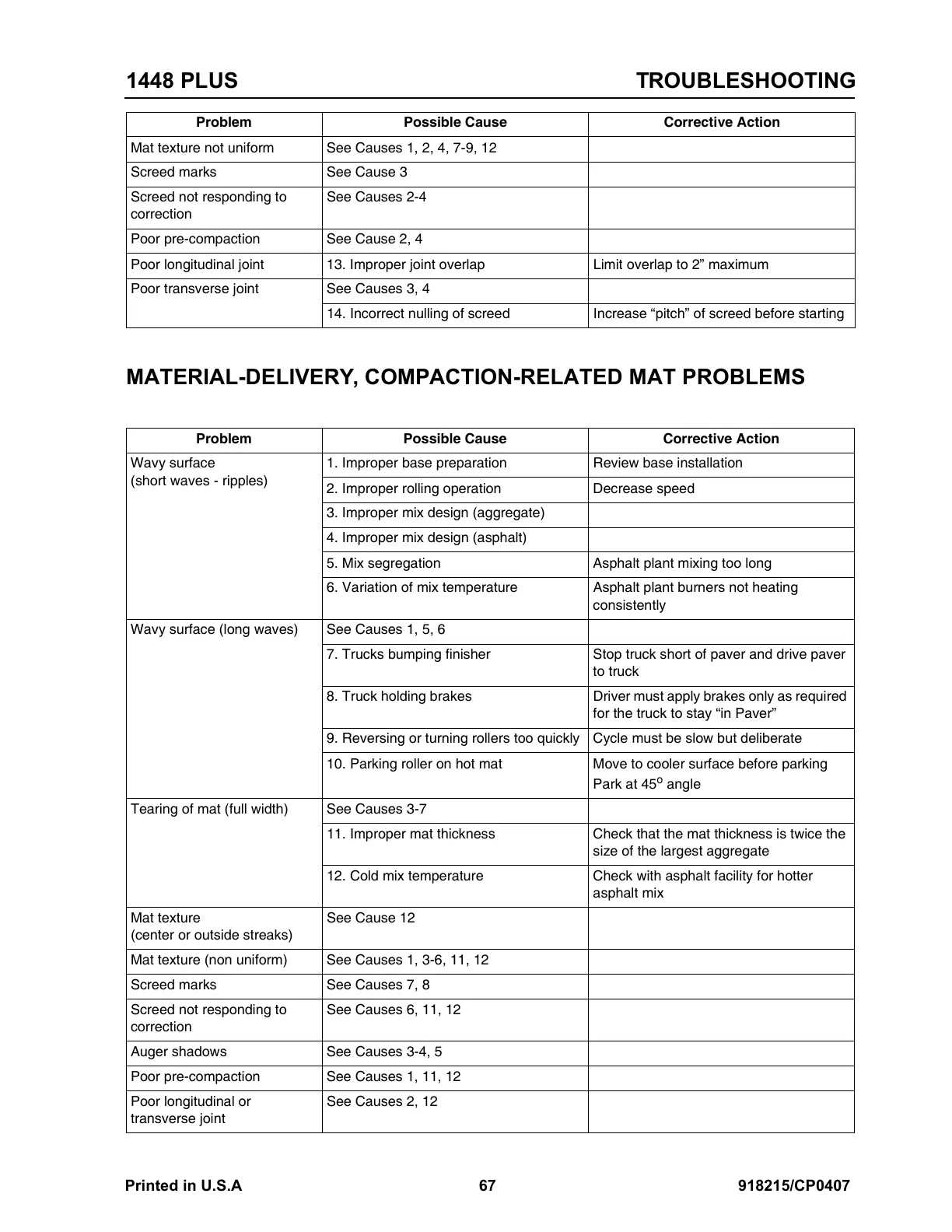

1448 PLUS TROUBLESHOOTING

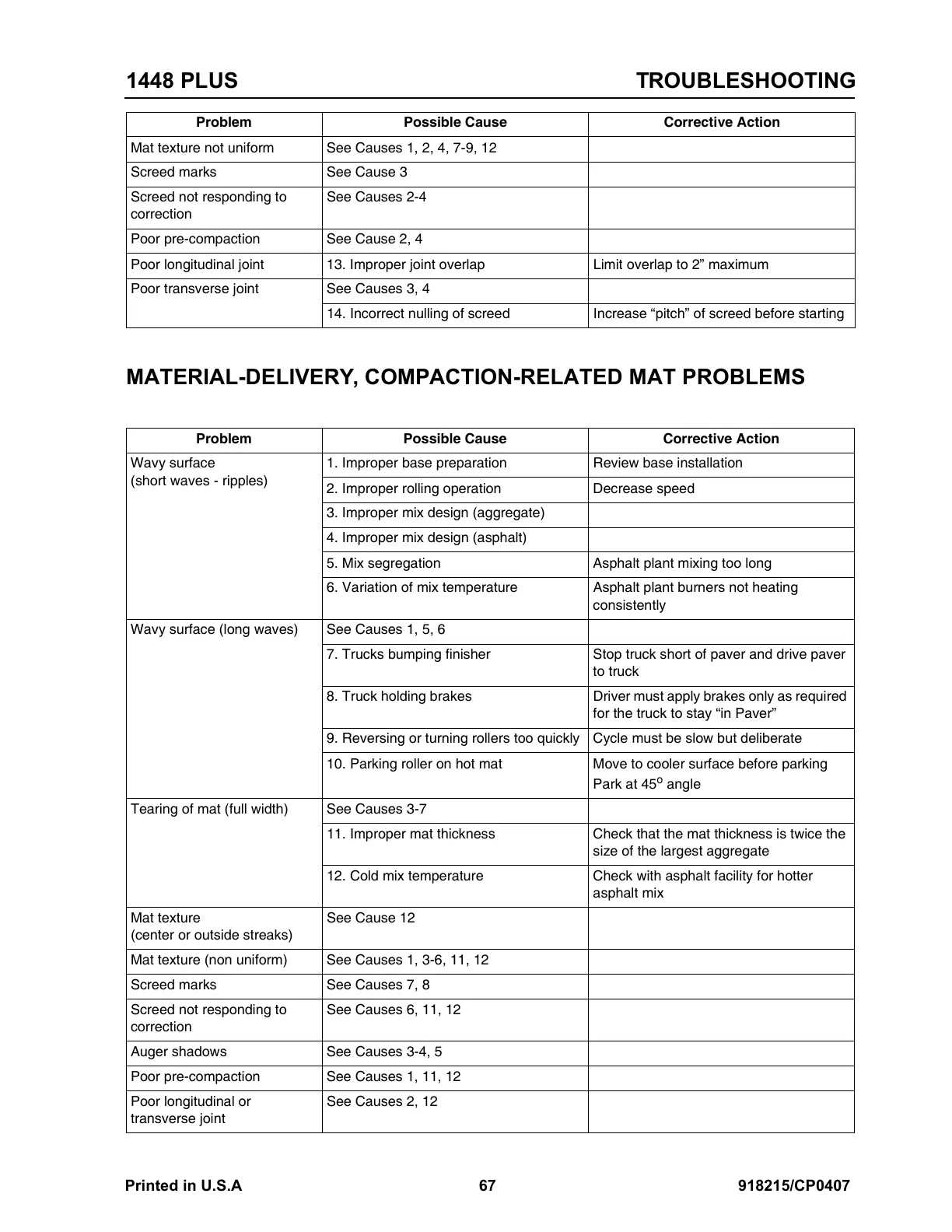

MATERIAL-DELIVERY, COMPACTION-RELATED MAT PROBLEMS

Mat texture not uniform See Causes 1, 2, 4, 7-9, 12

Screed marks See Cause 3

Screed not responding to

correction

See Causes 2-4

Poor pre-compaction See Cause 2, 4

Poor longitudinal joint 13. Improper joint overlap Limit overlap to 2” maximum

Poor transverse joint See Causes 3, 4

14. Incorrect nulling of screed Increase “pitch” of screed before starting

Problem Possible Cause Corrective Action

Problem Possible Cause Corrective Action

Wavy surface

(short waves - ripples)

1. Improper base preparation Review base installation

2. Improper rolling operation Decrease speed

3. Improper mix design (aggregate)

4. Improper mix design (asphalt)

5. Mix segregation Asphalt plant mixing too long

6. Variation of mix temperature Asphalt plant burners not heating

consistently

Wavy surface (long waves) See Causes 1, 5, 6

7. Trucks bumping finisher Stop truck short of paver and drive paver

to truck

8. Truck holding brakes Driver must apply brakes only as required

for the truck to stay “in Paver”

9. Reversing or turning rollers too quickly Cycle must be slow but deliberate

10. Parking roller on hot mat Move to cooler surface before parking

Park at 45

o

angle

Tearing of mat (full width) See Causes 3-7

11. Improper mat thickness Check that the mat thickness is twice the

size of the largest aggregate

12. Cold mix temperature Check with asphalt facility for hotter

asphalt mix

Mat texture

(center or outside streaks)

See Cause 12

Mat texture (non uniform) See Causes 1, 3-6, 11, 12

Screed marks See Causes 7, 8

Screed not responding to

correction

See Causes 6, 11, 12

Auger shadows See Causes 3-4, 5

Poor pre-compaction See Causes 1, 11, 12

Poor longitudinal or

transverse joint

See Causes 2, 12

Courtesy of Machine.Market

Loading...

Loading...