16

- For a proper operation of the softener, do not make any extension on

the power supply cable.

- After installation, make sure that the unit does not stand on the power

supply cable.

- Install a filter (6) between the by-pass for the cutting out of the system

and the water inlet of the softener.

- Use flexible hoses or vibration-damping joints for in-out connections

of the softener to the system.

- Connect the drain hose of the valve and the overflow hose of the salt

container to the drain with two separate hoses (supplied with the

system – see installation drawings). IMPORTANT: The drain must be

free (at atmospheric pressure) and not sealed.

- Provide a raceway drain pipe with enough draining capacity.

- The drain must be lower than the

“overflow” level of the tank.

- For pressures below 1.5 atm. a surge

tank shall be installed.

- For pressures above 1.5 atm. a

pressure reducer shall be installed.

- A non-return valve shall be installed after the water meter.

- For potable use a residual water hardness of 15 °f is recommended.

After installation, for start up and testing of the equipment, directly

contact your dealer or installer from whom you have purchased the

machine.

Do not use the equipment before the start up and testing carried out by

your dealer or authorized technical staff.

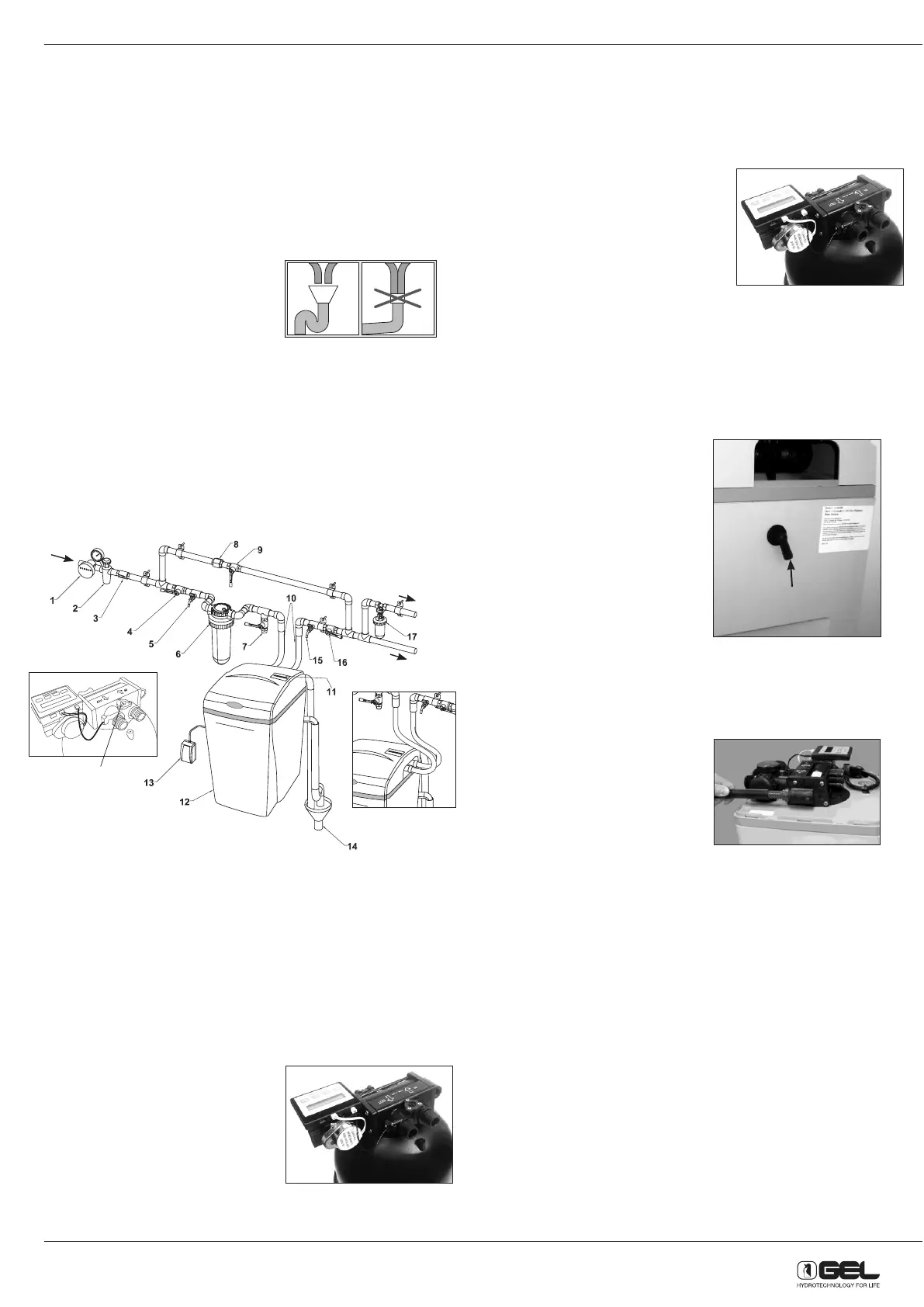

9.2 - INSTALLATION

1) Water meter

2) Pressure reducer (only if necessary)

3) Check valve

4) On-off valve before the system

5) Tap for raw water sample taking

6) Sand filter

7) Filtered water offtake for other uses

8) Pipe union fitting

9) By-pass gate valve

10) Flexible hoses or vibration-damping joints

11) Timer display

12) Brine cabinet

13) Power supply

14) Drains

15) Tap for soft water sample taking

16) On-off valve after the system

17) Anti-scale dosing unit (for boiler protection)

18) Mixing valve

9.3 - INSTALLATION STEPS

9.3.1 Turn off water supply

A. Turn off the water supply.

B. Open the hot and cold water taps to depressurize the lines.

9.3.2 Connect water softener

A. Remove valve cover.

1. Open the salt port lid on the valve cover

and slide it down.

2. Place your fingertips on the bottom,

inner edge of the valve cover (you may

need to use two hands).

3. Squeeze the edge and pull the valve

cover toward yourself until it clicks free

(See Figure 3)

4. Lift and remove the valve cover.

B. Attach the water lines to the appliance in compliance with all state and

local regulations (Figure 1). Do NOT overtighten the connections on

the plastic threads.

C. Check the arrows on the valve to ensure that the water flows in the

proper direction.

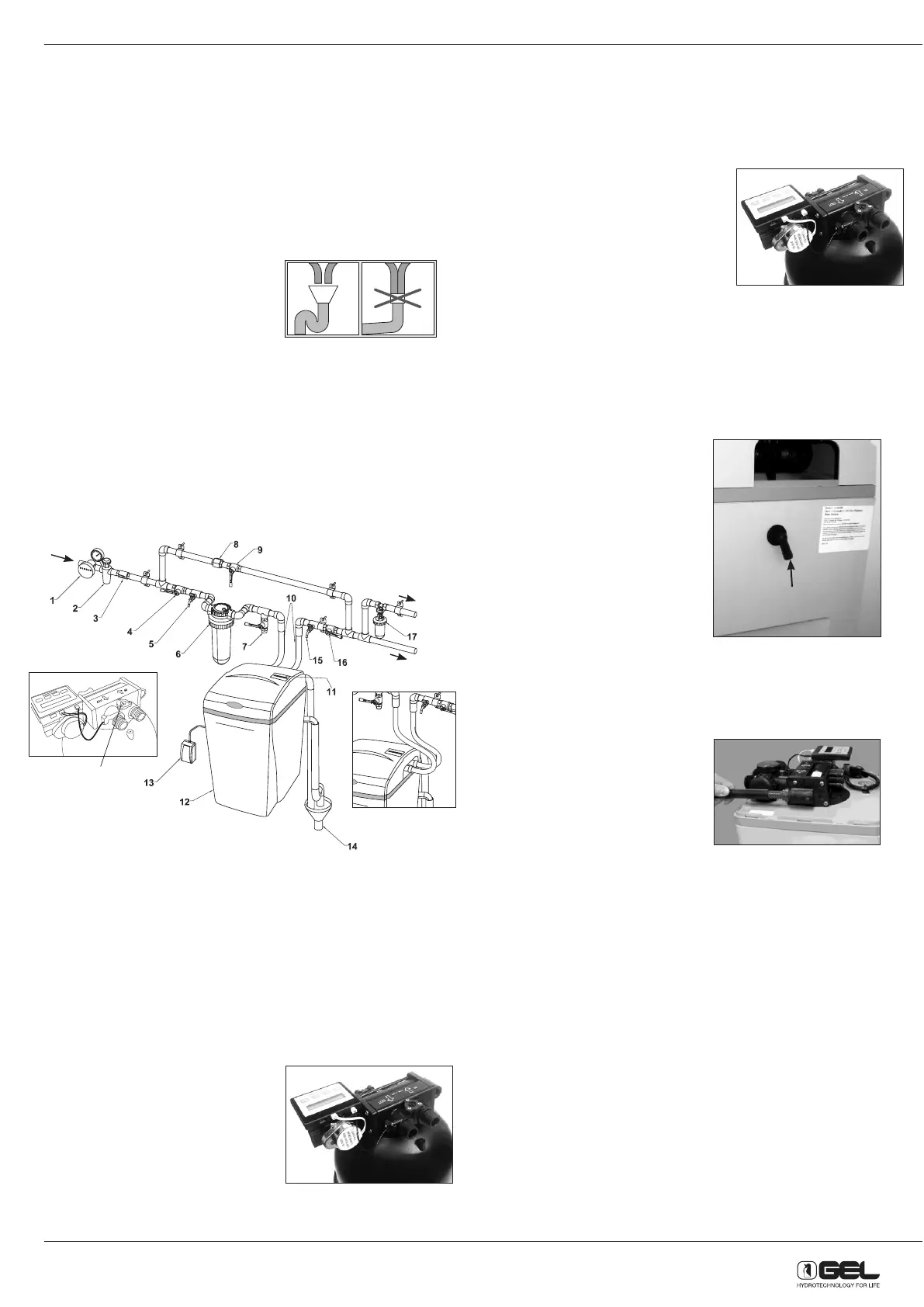

9.3.3 Connect overflow connection

The overflow line drains away excess

water, should the tank fill with too much

water or the appliance malfunction.

A. Check that the overflow elbow is in

the down position (Figure 2).

B. Connect with a 1/2-inch I.D. tubing

(size cannot be reduced) the

overflow elbow to a suitable waste

receptor. This tubing is not supplied

with the appliance. Ensure that the

overflow line ends at a drain that is

at least 8 cm lower than the bottom

of the overflow elbow. Maintain a

minimum 5 cm air gap between the

drain line and the flood level rim of

the waste receptor to prevent back-siphoning. The drain line should

be the shortest possible. The overflow connection shall be connected

to a free drain line.

9.3.4 Connect drain line

The drain line carries away the backwash

water produced during the regeneration

cycle.

A. Connect the drain line to the drain

end cap (Figure 3) with a minimum

5/8-inch I.D. tubing (supplied). The

size cannot be reduced.

B. Connect the drain line to a suitable

waste receptor. Maintain a

minimum 5 cm air gap between the drain line and the flood level

rim of the waste receptor to prevent back-siphoning. This drain line

should be the shortest possible.

C. The drain line may be elevated up to 2.4 m from the discharge on the

appliance as long as the water pressure in your system is 2.8 bar or

more.

D. If the drain line is longer than 7.6 m, increase the drain line to 3/4-inch

I.D. The end of the drain line must be equal to or lower in height than

the control valve.

Caution: The drain line must not be kinked, crimped, or restricted in

any way.

9.3.5 Flush Lines

A. Place the appliance in the bypass position (Figure 4).

B. Turn on the water supply valve.

C. Open the nearest cold water faucet to flush the plumbing of any

excess soldering flux, air, or any other foreign material.

SI NO

YES NO

Water

supply

entry

to the boiler

to the system

18

P.S. Inlet connections

in the MINI model are

on a side.

Overflow

elbow

Fig. 2

Loading...

Loading...