550_us

38 / 44

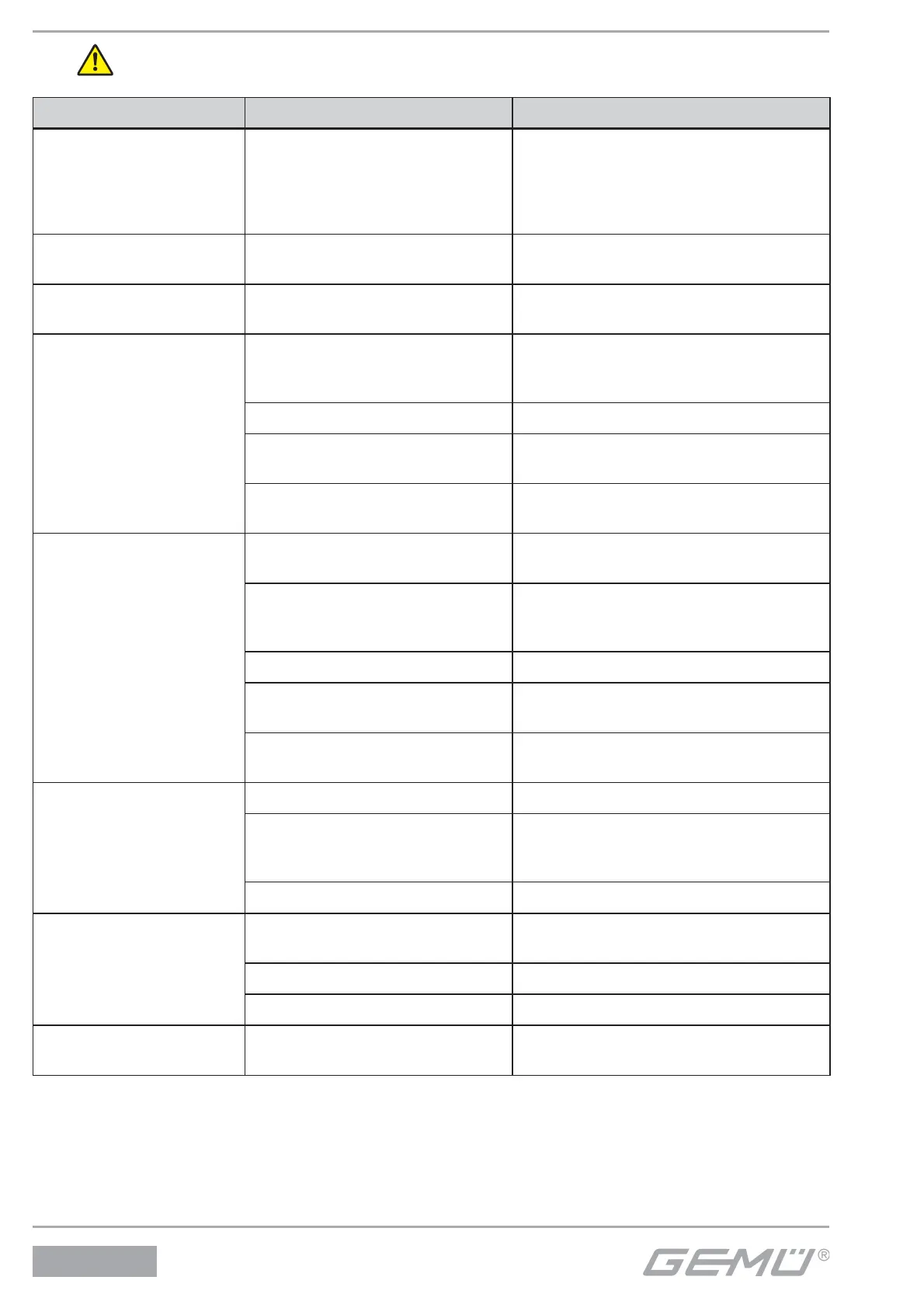

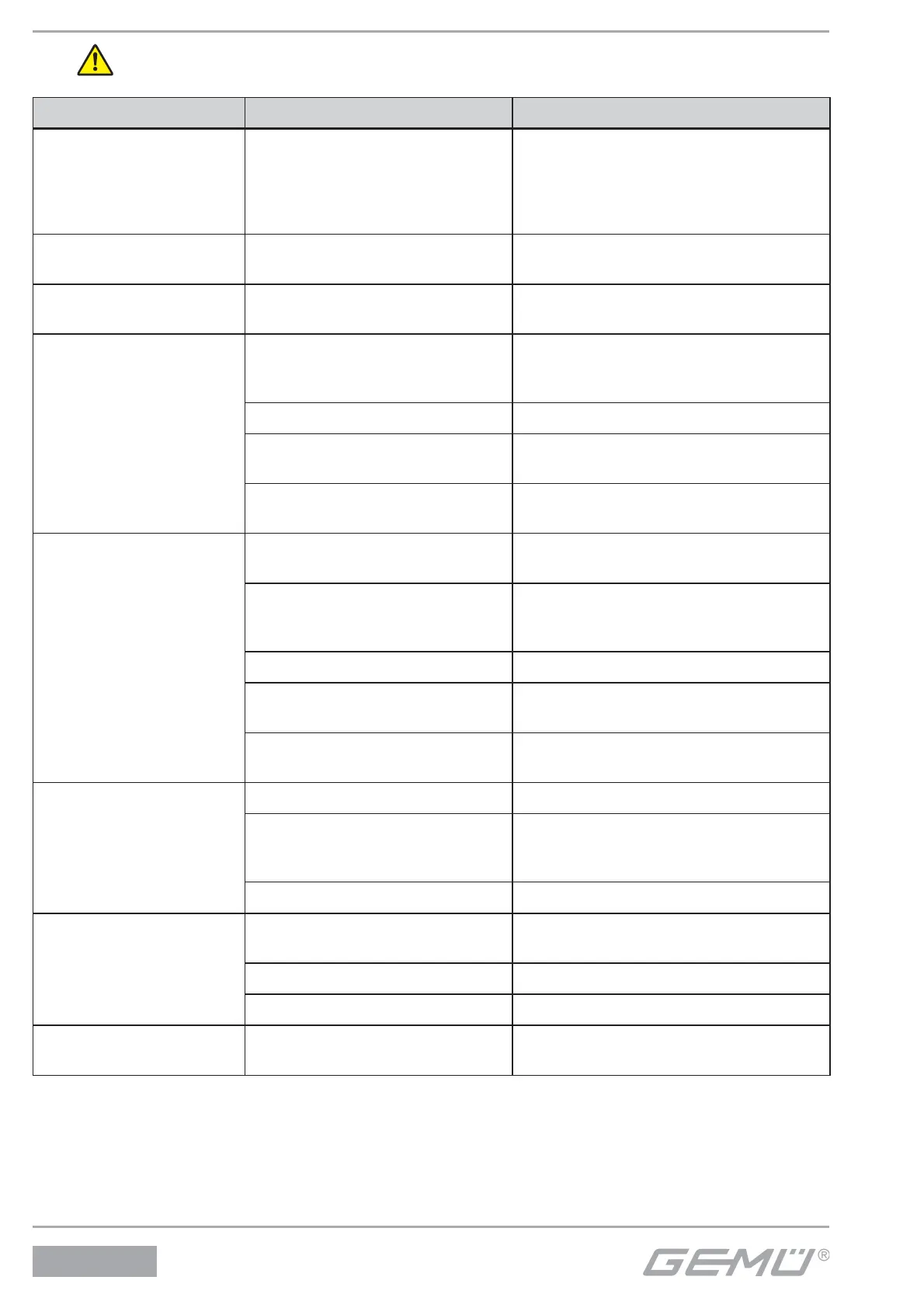

19 Troubleshooting / Fault clearance

Fault Possible cause Fault clearance

Control medium escapes from

vent hole* in the actuator

cover (for control function 1

(NC)) or connector 2* (for

control function 2 (NO))

Control piston leaky

Replace actuator and check control medium

for impurities

Control medium escapes

from the leak detection hole*

Spindle seal leaking

Replace actuator and check control medium

for impurities

Medium escapes from the

leak detection hole*

Gland packing faulty Replace actuator

Valve doesn't open or

doesn't open fully

Control pressure too low

Set control pressure in accordance with

data sheet. Check pilot valve and replace if

necessary

Control medium not connected Connect control medium

Control piston or spindle sealing

leaky

Replace actuator and check control medium

for impurities

Actuator spring faulty (for control

function 2, normally open (NO))

Replace actuator

Valve leaks downstream

(doesn't close or doesn't

close fully)

Operating pressure too high

Operate valve with operating pressure

specifi ed in data sheet

Foreign matter between seat seal

and seat (see sectional drawing)

Disassemble actuator, remove foreign

matter, check seat seal for damage and

replace if necessary

Valve body leaky or damaged Check valve body and replace if necessary

Seat seal faulty (see sectional

drawing)

Check seat seal for damage and replace if

necessary

Actuator spring faulty (for control

function 1, normally closed (NC))

Replace actuator

Valve leaks between actua-

tor and valve body

Union nut loose Retighten union nut

Gasket faulty (see sectional drawing)

Check gasket and the respective sealing

surfaces for damage and replace parts if

necessary

Valve body damaged Replace valve body

Valve body connection to

piping leaks

Incorrect installation Check installation of valve body in piping

Bolting loose Tighten bolting

Sealing material faulty Replace sealing material

Valve body leaks Valve body leaks or is corroded

Check valve body for damage, replace valve

body if necessary

* see chapter 20 "Sectional drawing and spare parts"

Loading...

Loading...