36 / 64

613, 618

6.2 Technical data GEMÜ 618

Working medium

Corrosive, inert, gaseous and liquid media which have no

negative impact on the physical and chemical properties of

the body and diaphragm material.

Load resistor

32

Operating time

See actuator version (chapter 7.2) approx. 17 or 45 s

Protection class

IP 65 acc. to DIN 40050

Electrical data

Power supply

Uv = 24 V 50/60 Hz ± 10 %

Uv = 120 V 50/60 Hz ± 10 %

Uv = 230 V 50/60 Hz ± 10 %

Power consumption 3.5 VA

Rating 100 %

Electrical connection

2 x PG 13.5 (functional module versions AE, AP)

2 x round connector (Binder series 717), (functional module versions E1, E2, E3)

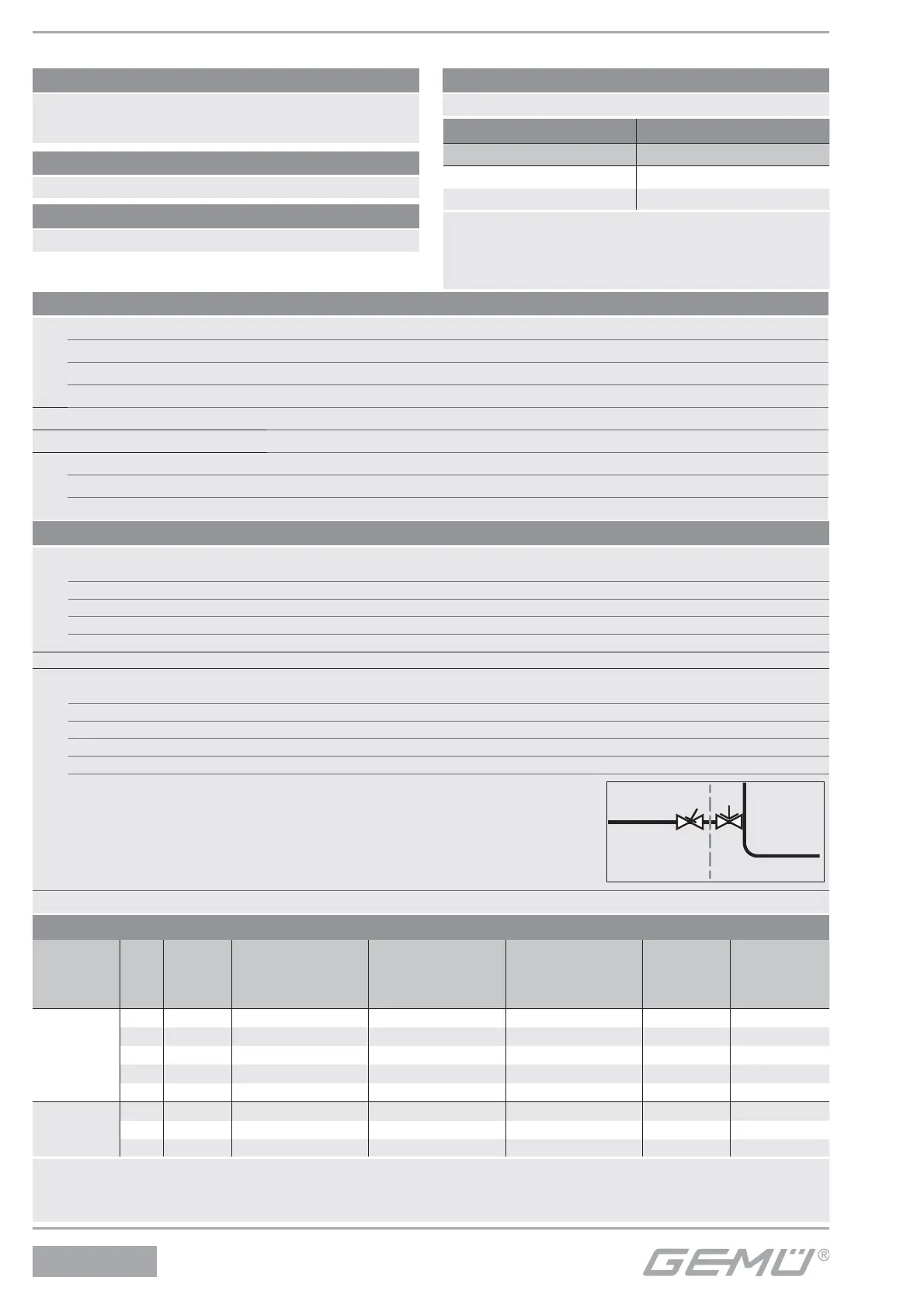

Kv values [m³/h]

Diaphragm

size

DN

DIN

Code 0

EN 10357

Series B / Code 16

EN 10357

Series A / Code 17

DIN 11850

Series 3 / Code 18

ASME BPE

Code 59

ISO 1127 /

EN 10357

Series C

Code 60

8

004 0.5 - - - - -

006 1.1 - - - - 1.2

008 1.3 - - - 0.6 2.2

010 - 2.1 2.1 2.1 1.3 -

015 - - - - 2.0 -

10

10 - 2.4 2.4 2.4 2.2 3.3

15 3.3 3.8 3.8 3.8 2.2 4.0

20 - - - - 3.8 -

Kv values determined acc. to DIN EN 60534, inlet pressure 5 bar, p 1 bar, PVC-U valve body and soft elastomer diaphragm.

The Kv values for other product configurations (e.g. other diaphragm or body materials) may differ. In general, all diaphragms are subject to

the influences of pressure, temperature, the process and their tightening torques. Therefore the Kv values may exceed the tolerance limits of

the standard.

Diaphragm size Operating pressure

[bar]

8 0 - 6

10 0 - 6

All pressures are gauge pressures. Operating pressure values were

determined with static operating pressure applied on one side of a

closed valve. Sealing at the valve seat and atmospheric sealing is

ensured for the given values. Information on operating pressures

applied on both sides and for high purity media on request.

Temperatures

Media temperature

FPM (Code 4/4A) Direct mount -10 ... 60 °C With distance piece -10 ... 90 °C*

EPDM (Code 13/3A) Direct mount -10 ... 60 °C With distance piece -10 ... 100 °C*

EPDM (Code 14) Direct mount -10 ... 60 °C With distance piece -10 ... 90 °C*

EPDM (Code 17) Direct mount -10 ... 60 °C With distance piece -10 ... 100 °C*

PTFE (Code 52/5A) Direct mount -10 ... 60 °C With distance piece -10 ... 100 °C*

* only actuator version with distance piece (code B0 or B1)

Sterilisation temperature

(1)

FPM (Code 4/4A) not applicable

EPDM (Code 13/3A) 130 °C

(2)

, max. 60 min per cycle

EPDM (Code 14) not applicable

EPDM (Code 17) 130 °C

(2)

, max. 180 min per cycle

PTFE (Code 52/5A) max. 150 °C

(2)

, no time limit per cycle

¹ The sterilisation temperature is valid for steam (saturated steam) or superheated water.

² If the sterilisation temperatures listed above are applied to the EPDM diaphragms for longer periods of time,

the service life of the diaphragms will be reduced. In these cases, maintenance cycles must be adapted accordingly.

This also applies to PTFE diaphragms exposed to high temperature fluctuations.

PTFE diaphragms can also be used as moisture barriers; however, this will reduce their service life.

The maintenance cycles must be adapted accordingly.

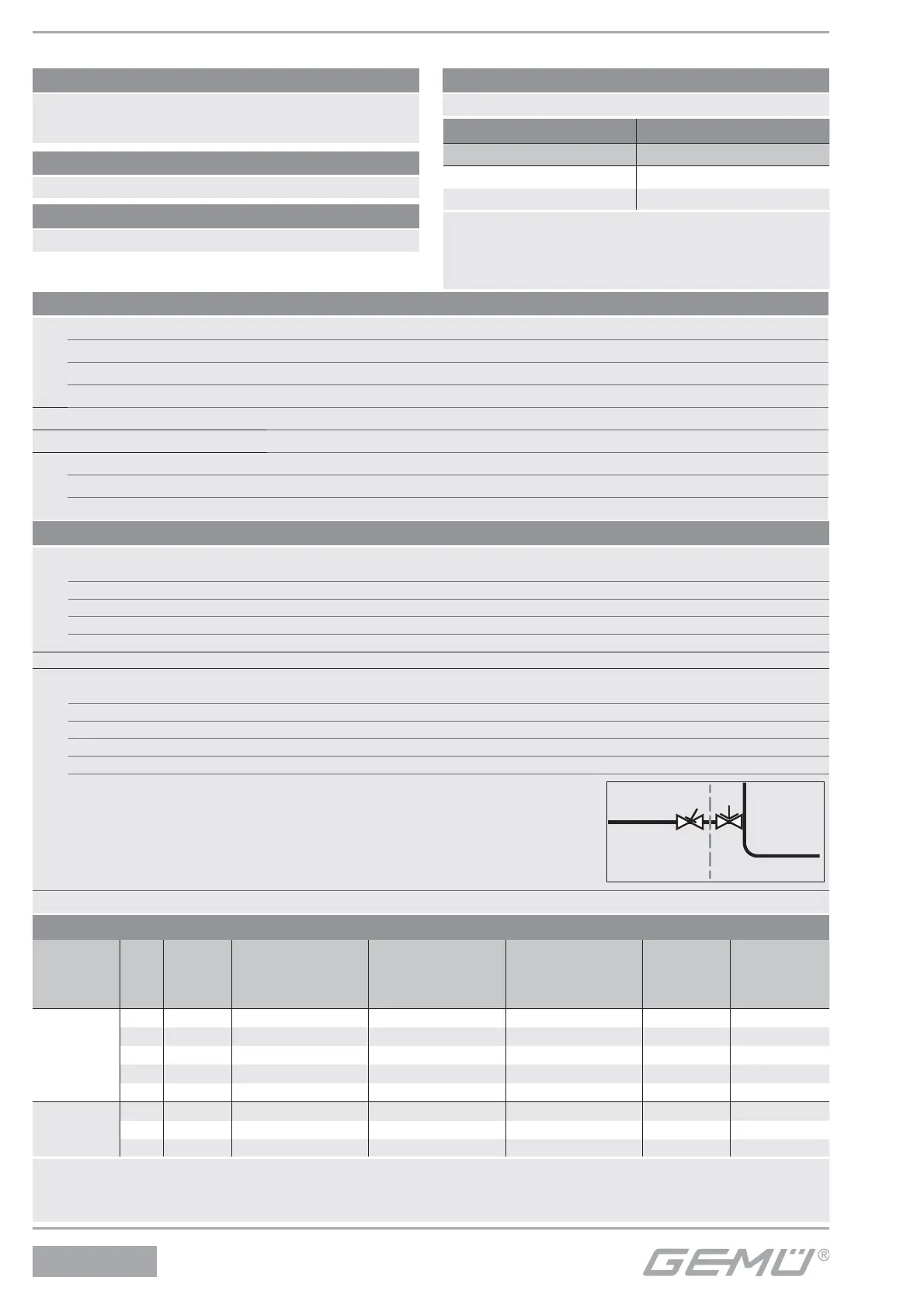

GEMÜ 555 and 505 globe valves are particularly suitable for use in the area of steam generation and distribution.

The following valve arrangement for interfaces between steam pipes and process pipes has proven itself over time:

A globe valve for shutting off steam pipes and a diaphragm valve as an interface to the process pipes.

Ambient temperature -15 ... 55 °C

Steam input

Process pipe

Steam distribution Sterile process

Loading...

Loading...