52 / 64

613, 618

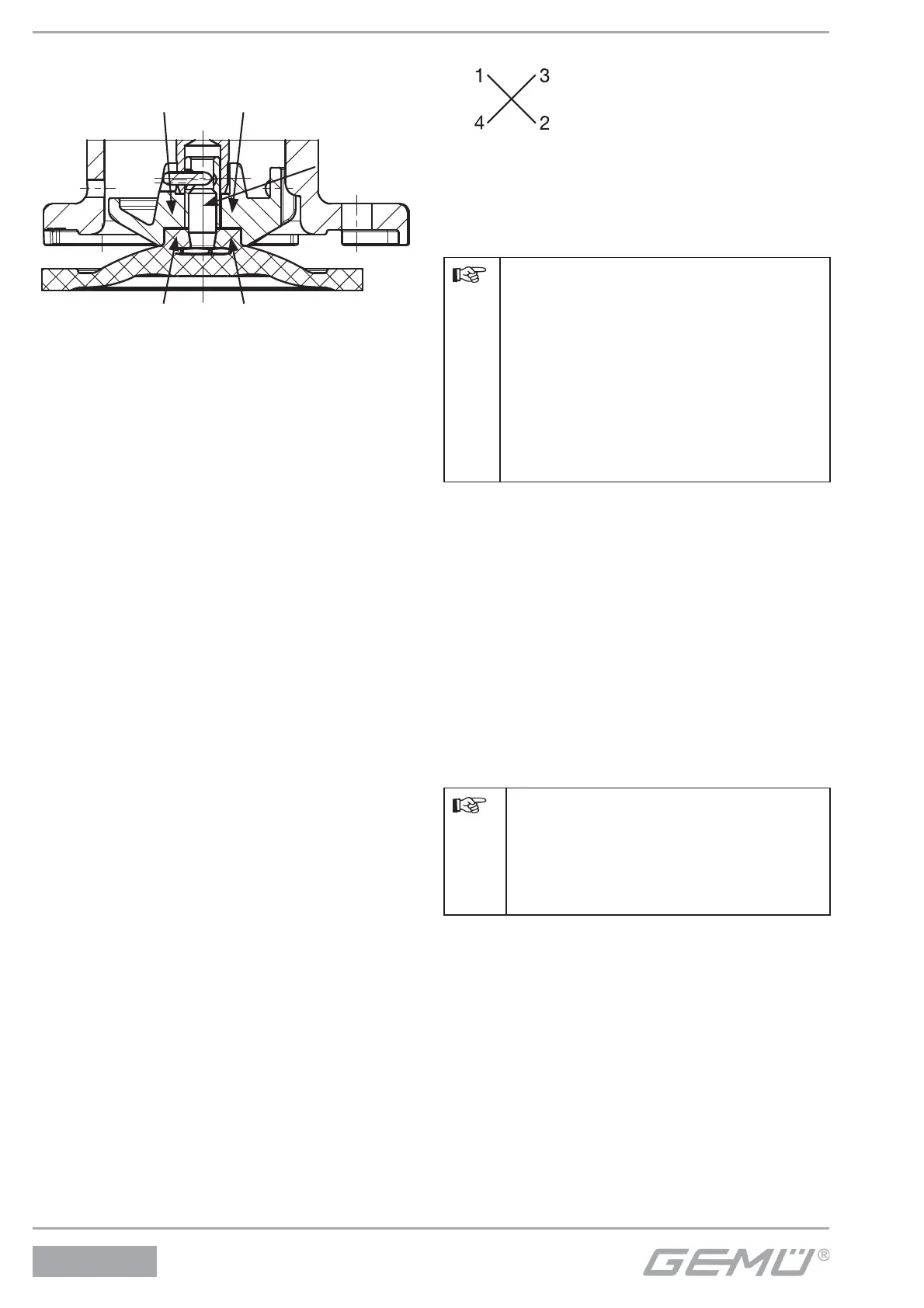

Diaphragm size 10

Threaded pin type diaphragm:

Diaphragm pin

Recess of compressor

Diaphragm boss

1. Move actuator A to the closed position.

2. Place the compressor loosely on the

actuator spindle, fi t the grooves into the

guides (see chapter 12.3.1 "General

information"). Diaphragm size 10: ensure

that the anti-twist system is engaged.

3. Check if the compressor fi ts closely in

the guides.

4. Screw new diaphragm tightly into the

compressor manually.

5. Check if the diaphragm boss fi ts closely

in the recess of the compressor.

6. If it is di cult to screw it in, check the

thread, replace damaged parts (only use

genuine parts from GEMÜ).

7. When clear resistance is felt turn back

the diaphragm anticlockwise until its bolt

holes are in correct alignment with the

bolt holes of the actuator.

13.4 Actuator mounting

on valve body

1. Move actuator A to the open position.

2. Open actuator A approx. 20 %.

3. Position actuator A with the mounted

diaphragm 2 on the valve body 1, take

care to align the compressor weir and

valve body weir (only for diaphragm

size 8).

4. Tighten bolts 18 with washers 19

by hand (hand tight only) (fastening

elements may vary dependent on

diaphragm size and / or valve body

version).

5. Fully tighten the bolts 18 diagonally.

6. Ensure that the diaphragm 2 is

compressed evenly (approx. 10-15 %,

visible by an even bulge to the outside).

7. Check tightness of completely

assembled valve.

Important:

Service and maintenance:

Diaphragms degrade in the course

of time. After valve disassembly /

assembly check that the bolts on

the body are tight and retighten

as necessary (GEMÜ 618: at the

very latest after the fi rst sterilisation

process).

13.5 Checking the valve seal

Install actuator into pipe (or testing

device).

Apply operating pressure to valve

(P = 6 bar).

Check / set seal by alternately turning

both transmission adjusting screws 1

(see photo page 50):

clockwise - tightness is increased

anticlockwise - tightness is decreased

Set the seal of the valve only as

high as absolutely necessary.

Setting the seal too high causes

unnecessary wear on the actuator

decreasing the life.

After checking the seal, both transmission

fastening screws 2 must be tightened in

order to fi x the transmission (see photo

page 50).

Replace cover (2 x SW10 screws).

Loading...

Loading...