Troubleshooting:

::

:

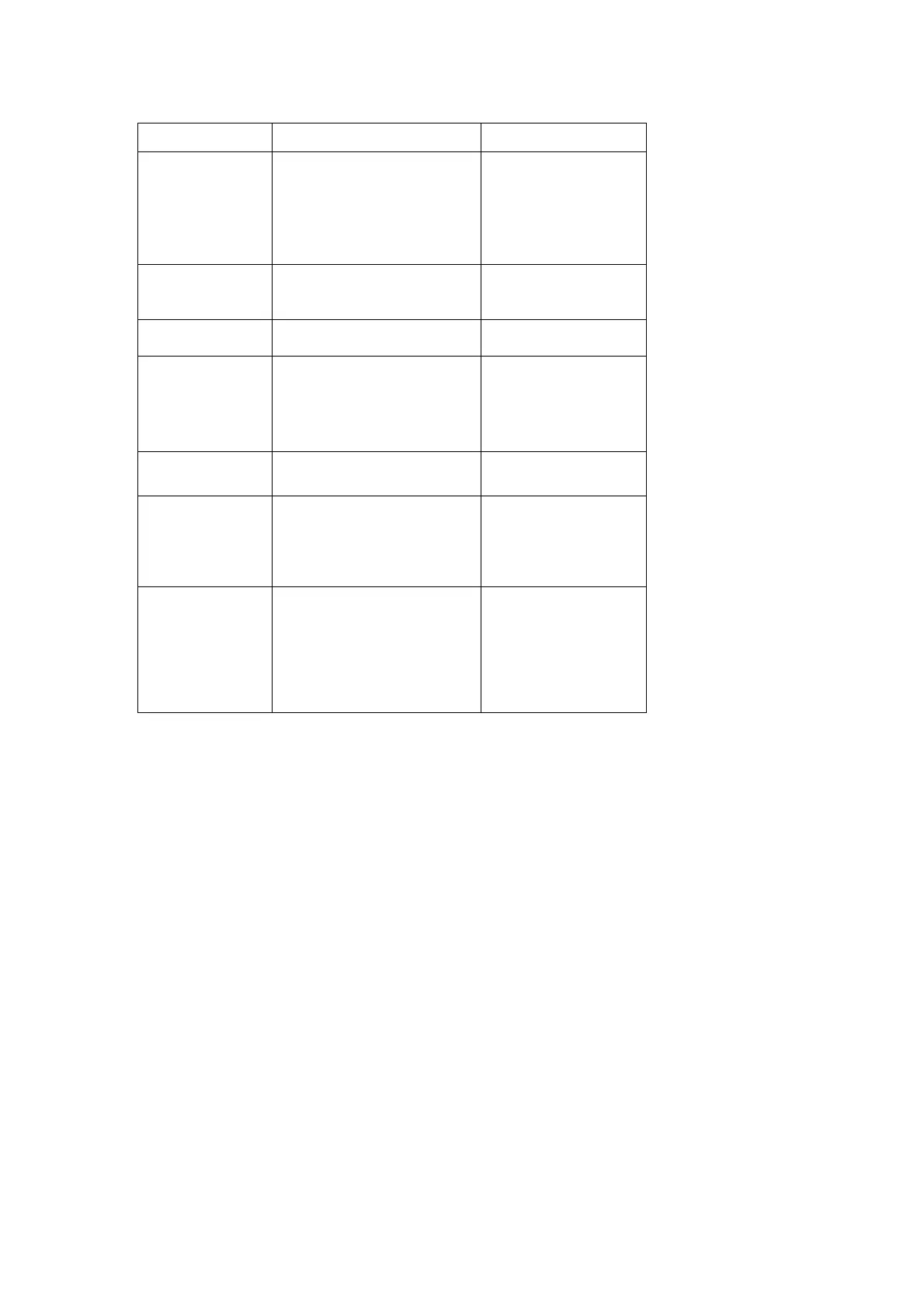

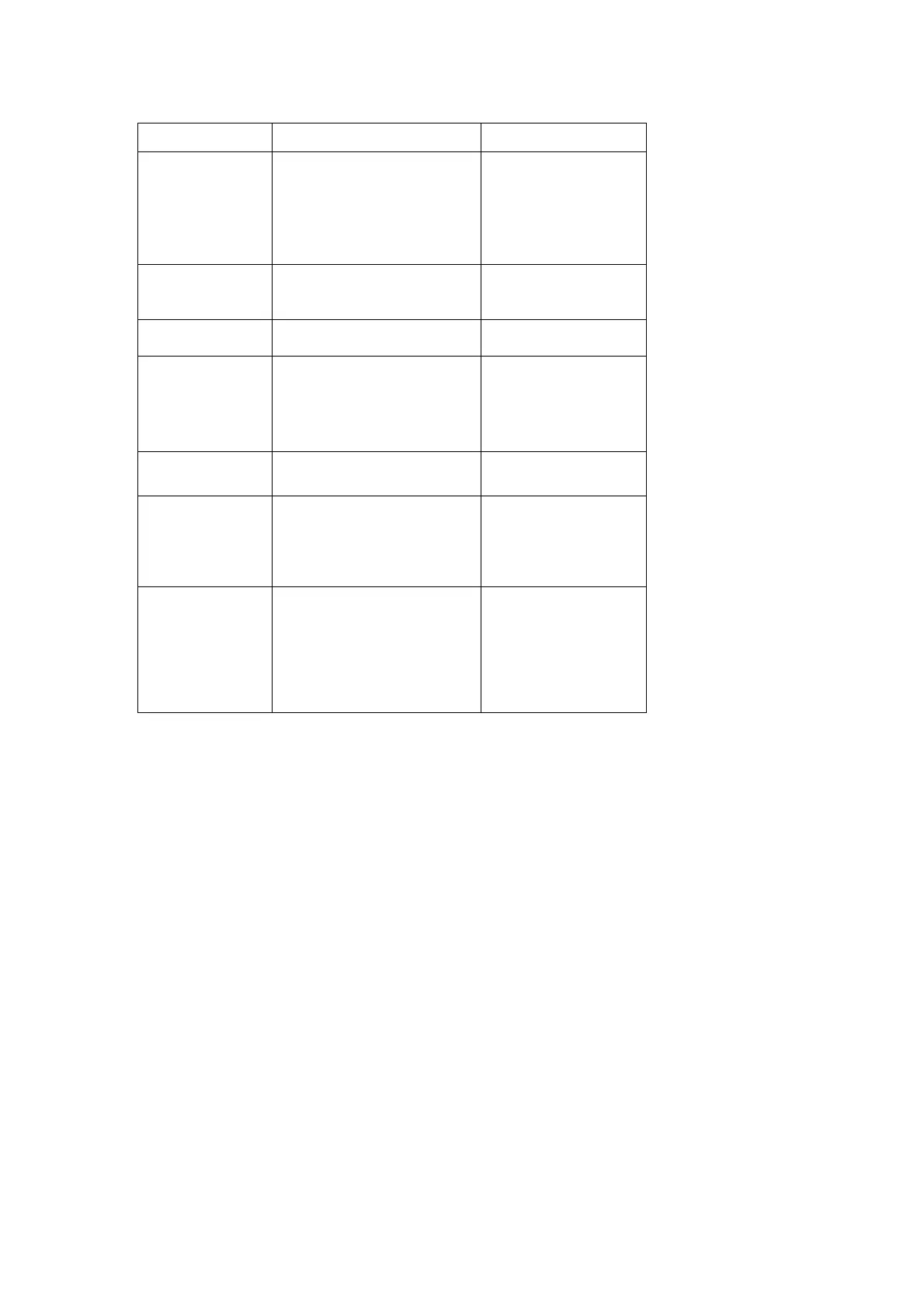

Problem Possible cause Corrective action

Can’t connect

power

- Blown fuse

- Disconnected linkage

- Defective power switch

- Worn carbon brushes

- Burnout motor

- Defective PCB

- Replace new one

- Connect linkage

- Replace new one

- Replace new one

- Replace new one

- Replace new one

Erratic Speed

- Worn carbon brushes

- Defective triac on PCB

- Defective resistance VR

- Replace new one

- Replace new one

- Replace VR

Vibration

- Imbalance rotor

Loosen rubber supports

- Adjust rotor

Tighten them

Imbalance

- Place tubes improperly

- Rotor does not screw

tightly

- Loose rubber supports

- Motor does not position

- Place tube diagonally

- Screw rotor tightly

- Screw rubber

supports properly

- Position motor

Noise

- Motor is tilted

- Loose Rubber supports

- Position motor

- Replace new ones

Fuse blew

- Loose SCR on PCB

- Short circuit in motor

- Over load

- Unstable power supply

-

replace the new SCR.

- Replace new motor

Properly operate

Use power stabilizer

Broken test tubes

- Tilt tubes

- Didn’t press tubes all way

down

- Didn’t place Lid of rotor

F-2415 properly.

- Corrosive silicon gasket

on rotor # F-2415

- Place tubes properly

- Place tubes all the

way down

- Cover the rotor lid

properly

- Replace the new

one

NOTE:

::

:

The drive motor and linkage assembly do not require lubrication

Disassembly must be performed under the supervision of licensed

engineers

Take care of the electrical shock for troubleshooting.

Call your distributor for troubleshooting.

11

Loading...

Loading...