上海鲍麦克斯电子科技有限公司 AS系列数控交流伺服系统说明书

11

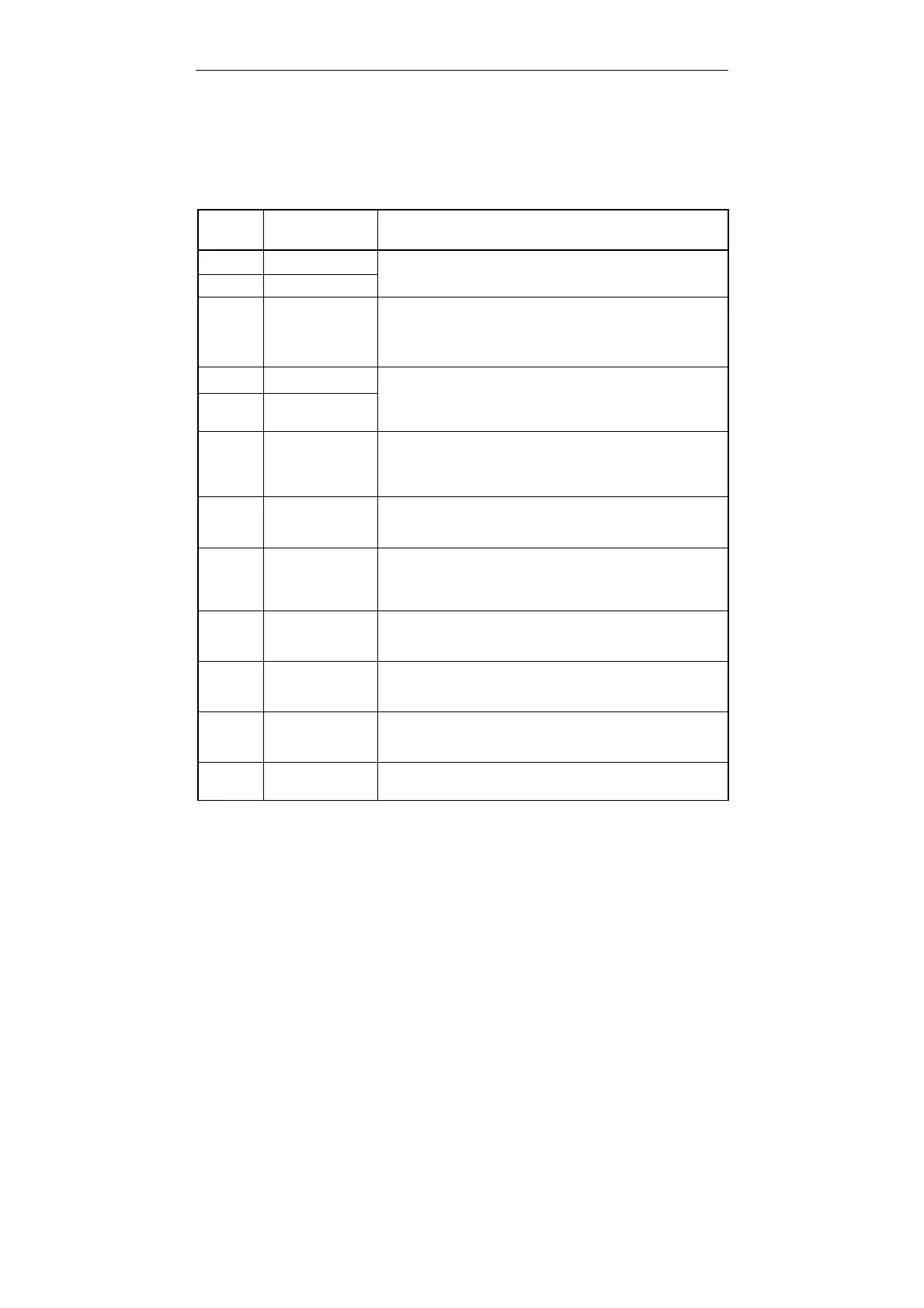

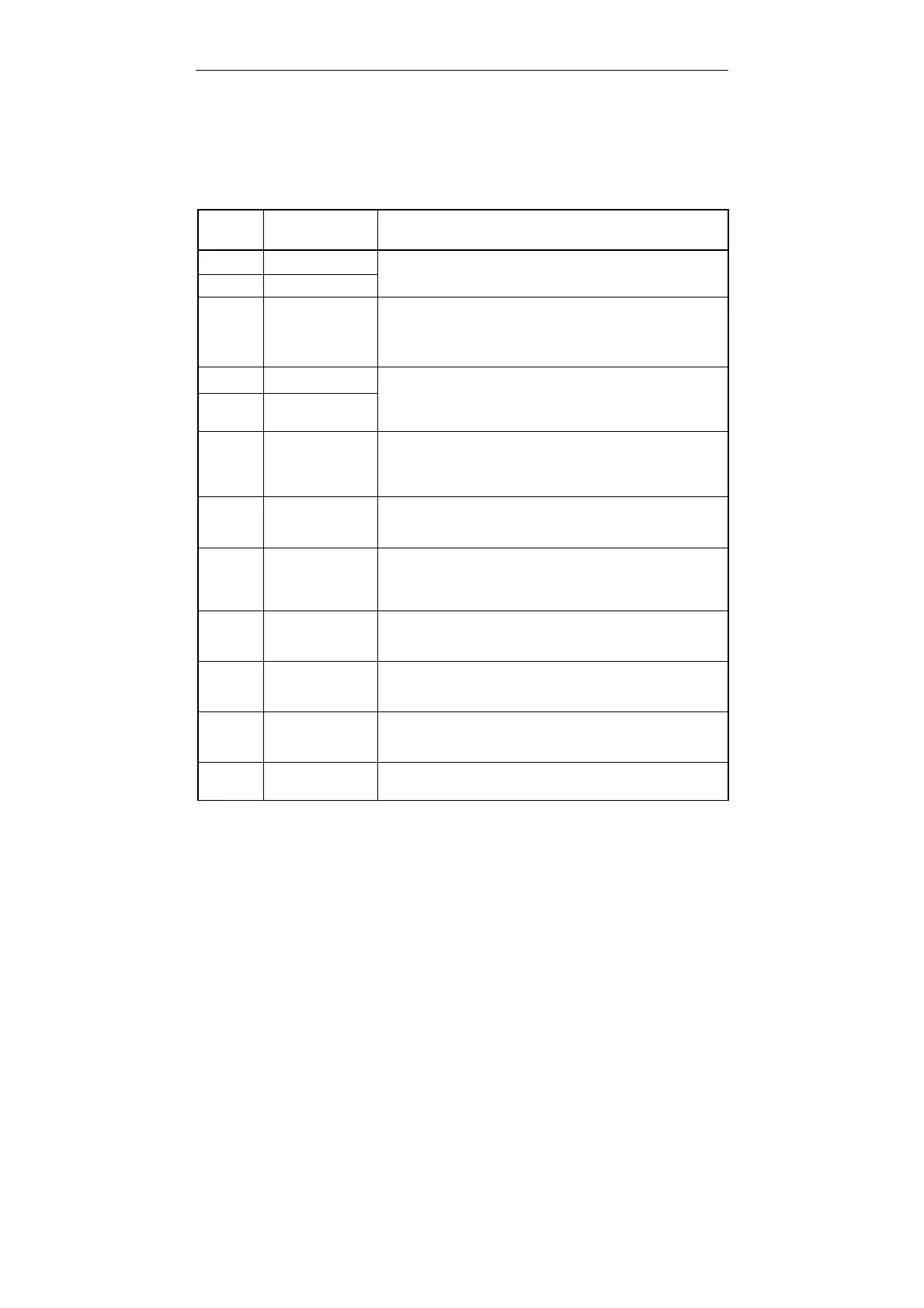

3.4 False alarm mode

If the system error or warning, please first check the following items:

1, to confirm the connection machine is connected properly;

2, confirm the control and head matches;

3, confirm restore factory is accurate.

error

code

meaning solution

Err-01

hardware overflow

Err-02 software overflow

Turn off the system power, restart after 30 seconds, if the controller

still does not work, please replace it and inform the manufacturer.

Err-03

system

under-voltage

Disconnect the controller power and check if the input voltage is

too low (lower than 176V). If yes, please restart the controller when

the normal voltage is resumed. If the controller still does not work

when the voltage is at normal level, please replace the controller

and inform the manufacturer.

Err-04

over-voltage when

the machine is off

Err-05

over-voltage in

operation

Disconnect the controller power and check if the input voltage is

too high (higher than 264V). If yes, please restart the controller

when the normal voltage is resumed. If the controller still does not

work when the voltage is at normal level, please replace the

controller and inform the manufacturer.

Err-06

solenoid circuit

failure

Turn off the system power, check if the solenoid is connected

correctly and if it is loose or damaged. If yes, replace it in time.

Restart the system upon making sure everything is in good order.

If it still does not work, seek technical support.

Err-07

electrical current

checking circuit

failure

Turn off the system power, restart after 30 seconds to see if it

works well. If not, try several more times. If such failure happens

frequently, seek technical support.

Err-08

locked motor roller

Disconnect the controller power, check if the motor input plug is off,

loose or damaged, or if there is something twined on the machine

head. After checking and correction, if the system still does not

work, please replace the controller and inform the manufacturer.

Err-09

brake circuit failure

Turn off the system power, check if the white brake resistance plug

on the power board is loose or dropped off, fasten it and restart the

system. If it still does not work, please replace the controller and

inform the manufacturer.

Err-10

HMI communication

failure

Check if the connecting line between control panel and controller is

off, loose or broken, restore it and restart the system. If it still does

not work, please replace the controller and inform the

manufacturer.

Err-11

machine head

needle positioning

failure

Check if the connection line between machine head synchronizer

and controller is loose or not, restore it and restart the system. If it

still does not work, please replace the controller and inform the

manufacturer.

Err-12

motor original angle

checking failure

Please try 2 to 3 more times after power down, if it still does not

work, please replace the controller and inform the manufacturer.

Loading...

Loading...