ENGINE/DC CONTROL

PART 4

Page 123

Section 4.5

Diagnostic Tests

(propane) gas is heavier than air, and tends to settle

in low areas. Even the slightest spark can ignite these

gases and cause an explosion.

Procedure

A water manometer or a gauge that is calibrated in “ounces per

square inch” may be used to measure the fuel pressure. Fuel

pressure at the inlet side of the fuel solenoid valve should be

between 5-7 inches water column for natural gas (NG) or 10-12

inches water column for LP gas.

1. See Figures 124, 125 or 126 for the gas pressure test point

on the fuel regulator. The fuel pressure can be checked at

Port 1 on all fuel regulators, and at Port 3 on 12-20kW units.

2. With the manometer connected properly, crank the engine.

Nominal fuel pressure should be measured. If pressure is

not measured while cranking refer back to flow chart.

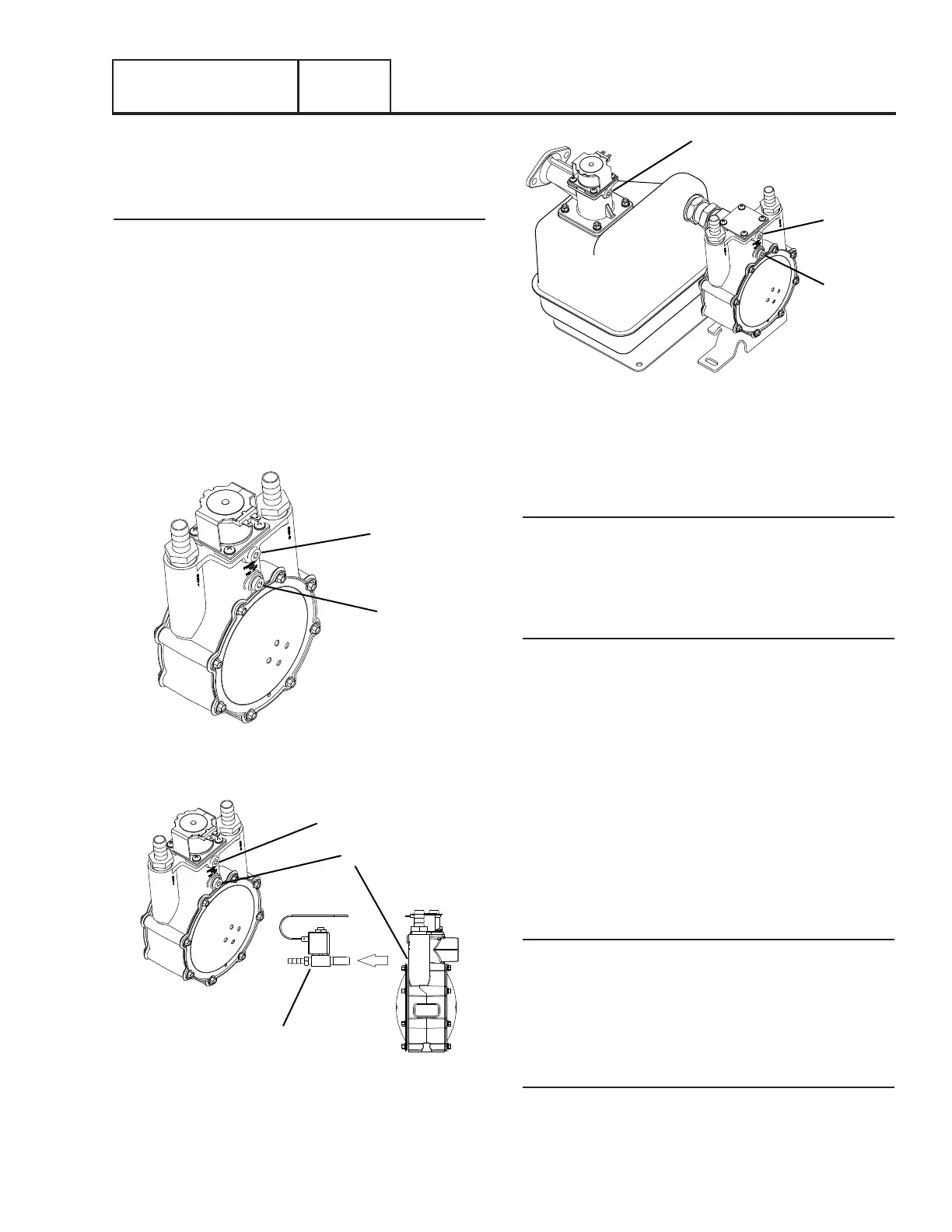

PORT 1

PORT 2

Figure 124. (8kW) Gas Pressure Test point

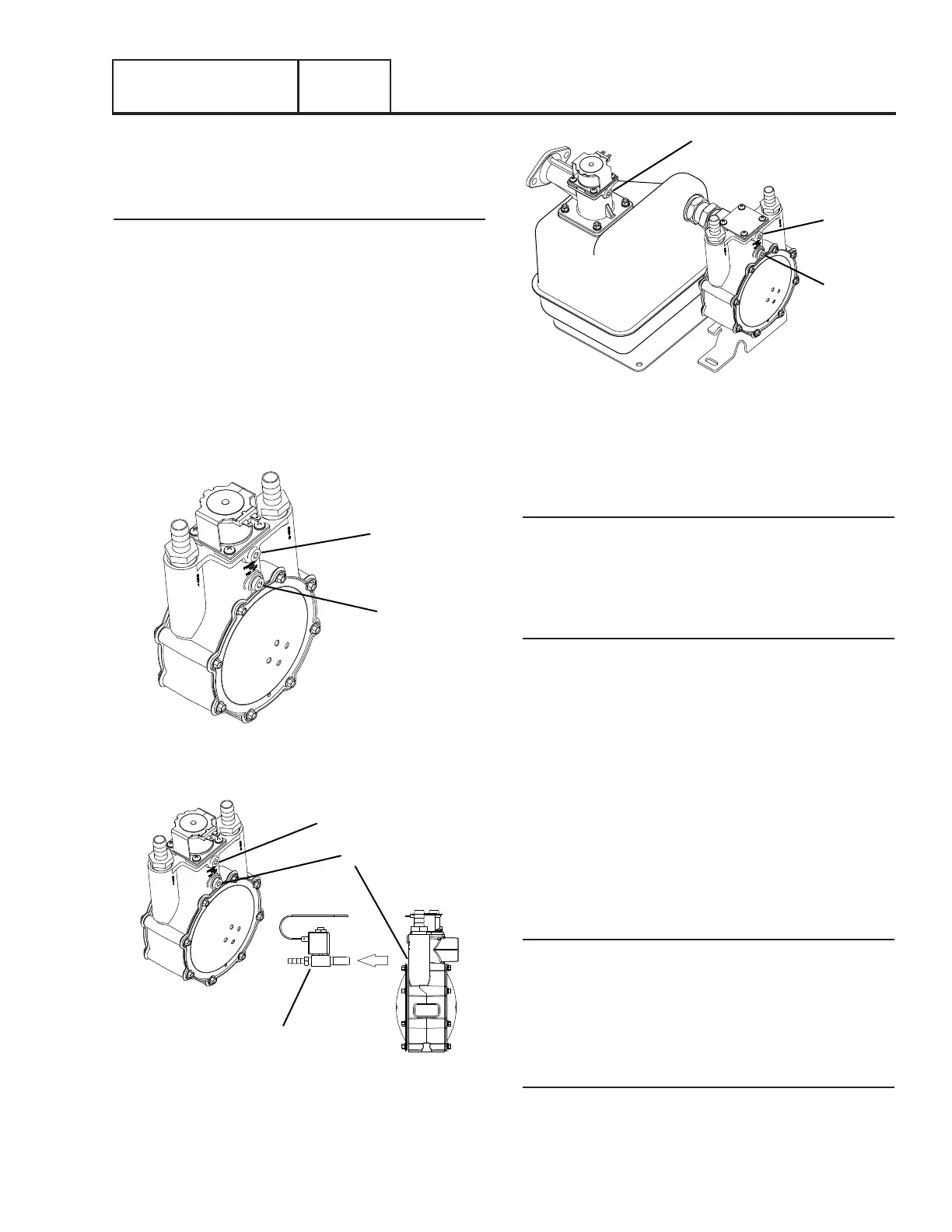

PORT 1

PORT 2

SOLENOID REMOVED

Figure 125. (10kW) Gas Pressure Test point

PORT 3

PORT 1

PORT 2

Figure 126. (12-20kW) Gas Pressure Test point

Note: Where a primary regulator is used to establish fuel

inlet pressure, adjustment of that regulator is usually the

responsibility of the fuel supplier or the fuel supply system

installer.

12-20kW Units Only

Note: The test port (Port 3) below the fuel solenoid may

be used to take a fuel pressure reading before the fuel

solenoid. Consistent pressure should be measured at this

port both while the generator is running and when the

generator is off.

Results

1. If fuel supply and pressure are adequate, but engine will

not start refer back to the flow chart.

2. If generator starts but runs rough or lacks power, repeat

the above procedure with the generator running and under

load. The fuel system must be able to maintain 10-12

inches water column at all load requirements for propane,

and 5-7 inches water column for natural gas. If proper

fuel supply and pressure is maintained, refer to Problem

17 Flow Chart.

TEST 51 – CHECK CONTROLLER WIRE 14

OUTPUTS

Discussion

During any crank attempt, the controllers crank relay and run

relays both are energized. When the run relay energizes, its

contacts close and 12 VDC is delivered to the Wire 14 circuit

and to the fuel solenoid. The solenoid energizes open to allow

fuel flow to the engine. This test will determine if the controller

is working properly.

Procedure

1. Set the AUTO-OFF-MANUAL switch to OFF.

2. Set a Volt-Ohm-Milliammeter (VOM) to measure DC

voltage.

Loading...

Loading...