ENGINE/DC CONTROL

PART 4

Section 4.5

Diagnostic Tests

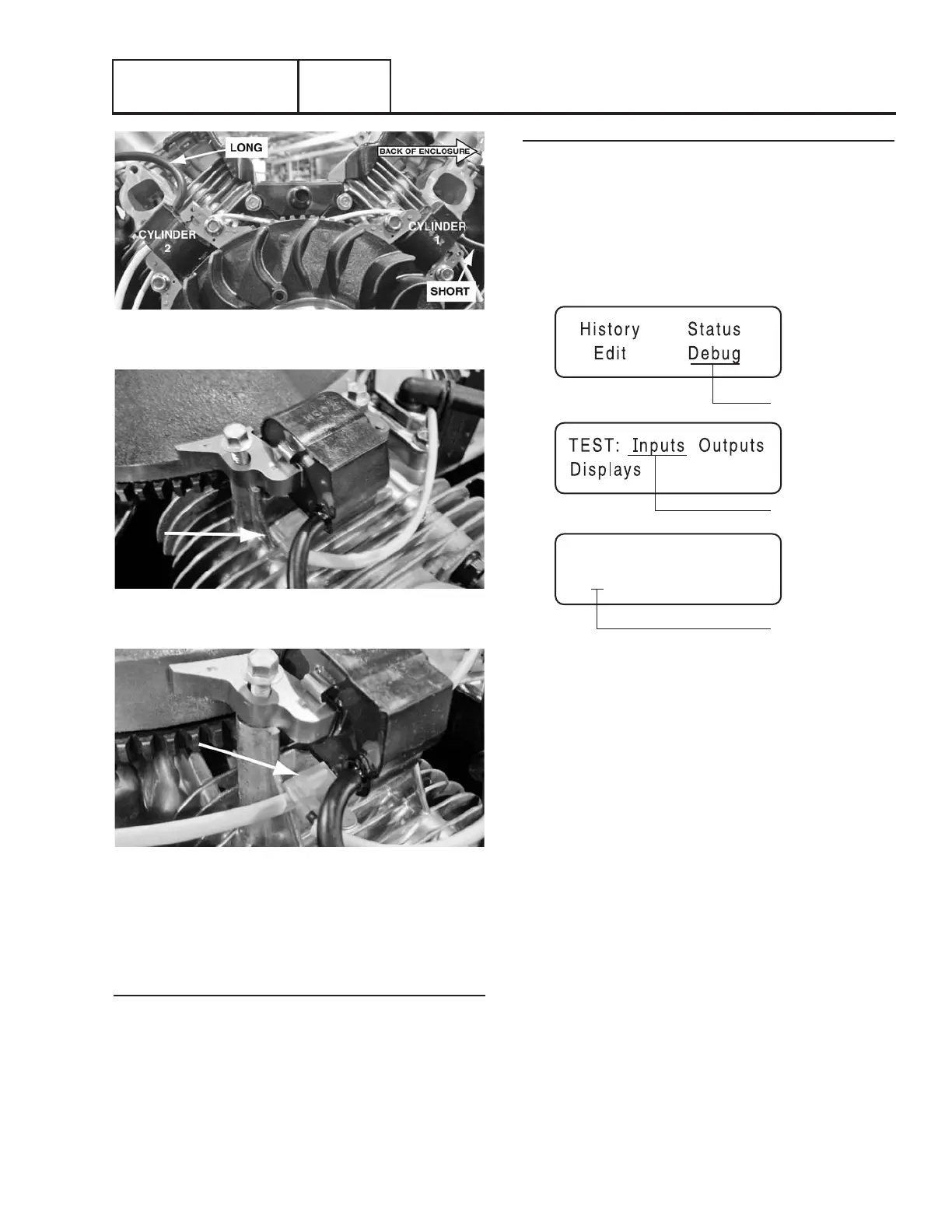

Figure 146.

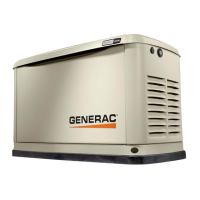

Figure 147.

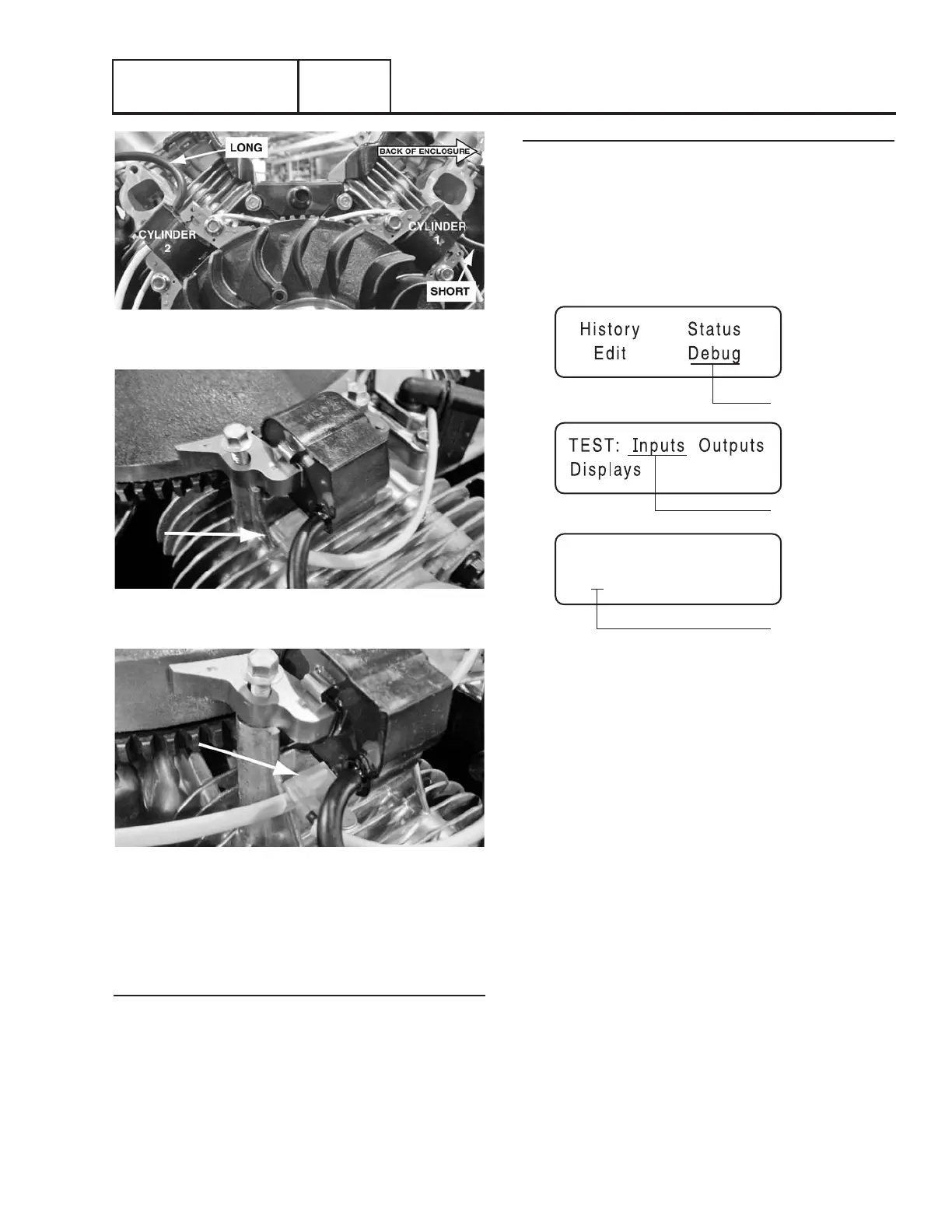

Figure 148.

TEST 61 – CHECK OIL PRESSURE SWITCH

AND WIRE 86

Discussion

If the oil pressure switch contacts have failed in their closed

position, the engine will crank and start, however shutdown will

occur within about 5 (five) seconds. If the engine cranks and

starts, then shuts down almost immediately with a Shutdown-

Alarm Low Oil Pressure, the cause may be one or more of the

following:

•Low engine oil level.

•Low oil pressure.

•A defective oil pressure switch.

Procedure

1. Navigate to the Digital inputs display screen.

a. Press “ESC” until the main menu is reached.

b. Press the right arrow key until “Debug” is flashing.

c. Press “Enter”.

d. Press the right arrow key until “Inputs” is flashing.

e. Press “Enter”.

DEBUG

INPUTS

INPUTS 1 - 8:

1 0 1 1 0 0 0 1

Figure 149. The Home Page, Debug and Input Screens

f. Digital Input 2 is Wire 86 from the Low Oil Pressure

switch to the board. Refer to Figure 149.

g. Set the AUTO-OFF-MANUAL switch to the MANUAL

position.

h. Observe Input 2 for a change from “1” to “0”. A change

from “1” to “0” indicates that the control board sensed

the LOP switch change states. If the generator still

shuts down, replace controller.

i. If the input did change states, the oil pressure switch

is good. An intermittent oil pressure problem may still

be present and should be checked with a mechanical

gauge as in Step 4.

2. Check engine crankcase oil level.

a. Check engine oil level.

b. If necessary, add the recommended oil to the dipstick

FULL mark. DO NOT OVERFILL ABOVE THE FULL

MARK.

3. With oil level correct, try starting the engine.

a. If engine still cranks and starts, but then shuts down,

go to Step 4.

b. If engine cranks and runs normally, discontinue tests.

4. Do the following:

a. Disconnect Wire 86 and Wire 0 from the oil pressure

switch terminals. Remove the switch and install an oil

pressure gauge in its place.

Page 133

Loading...

Loading...