GENERAL INFORMATION

PART 1

Section 1.2

Installation Basics

Page 11

INTRODUCTION

Information is provided in this section to ensure the service

technician will have a basic knowledge of installation

requirements for home standby systems. Installation problems

that arise often relate to poor or unauthorized installation

practices.

A typical home standby electric system is shown in Figure 7.

Installation of a system includes the following:

•Selecting a location

•Grounding the Generator

•Providing the fuel supply

•Mounting the load center

•Connecting power source and load lines

•Connecting system control wiring

•Post installation tests and adjustments

SELECTING A LOCATION

Install the Generator set as close as possible to the electrical

load distribution panel(s) that will be powered by the unit,

ensuring that there is proper ventilation for cooling air and

exhaust gases. This will reduce wiring and conduit lengths.

Wiring and conduit not only add to the cost of the installation,

but excessively long wiring runs can result in a voltage drop.

Control system interconnections between the transfer switch

and Generator consists of N1, N2, T1, 194, and 23. In addition,

a Wire 0 must be connected for use with Nexus Smart Switches.

Control system interconnection leads must be run in a conduit

that is separate from the AC power leads. Recommended wire

gauge size depends on length of the wire:

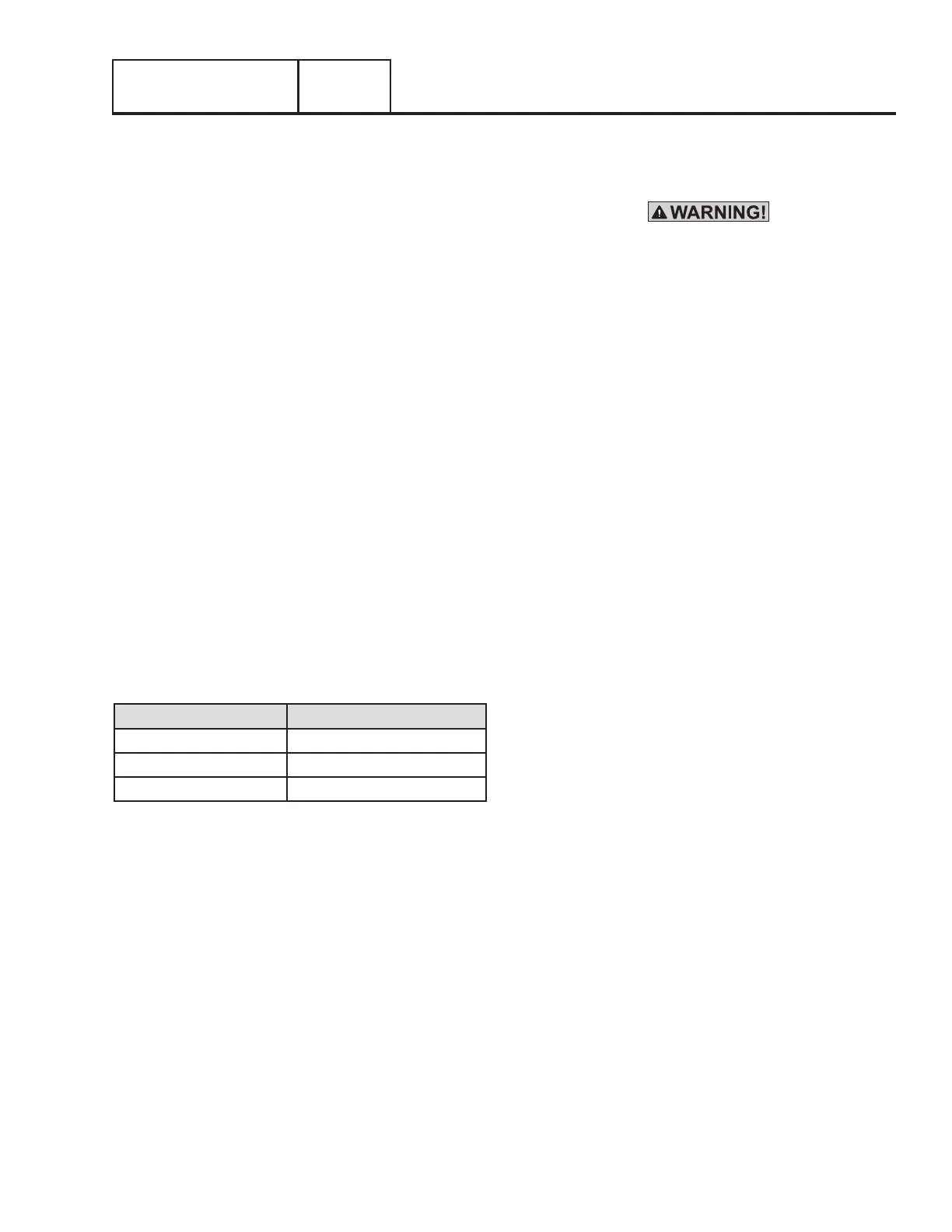

Max. Cable Length Recommended Wire Size

35 feet (10.67m) No. 16 AWG.

60 feet (I8.29m) No. 14 AWG.

90 feet (27.43m) No. 12 AWG.

NFPA 37 CODE REQUIREMENTS

The National Fire Protection Association (NFPA) has established

standards for the installation and use of stationary combustion

engines. This code limits the spacing of an enclosed Generator

set from a structure or wall. NFPA 37 states:

NFPA 37, Section 4.1.4, Engines Located Outdoors. Engines,

and their weatherproof housings if provided, that are installed

outdoors shall be located at least 5 feet from openings in walls

and at least 5 feet from structures having combustible walls. A

minimum separation shall not be required where the following

conditions exist:

1. The adjacent wall of the structure has a fire resistance

rating of at least 1 hour.

2. The weatherproof enclosure is constructed of

noncombustible materials and it has been demonstrated

that a fire within the enclosure will not ignite combustible

materials outside the enclosure.

Annex A — Explanatory Material

A4.1.4 (2) Means of demonstrating compliance are by means

of full-scale fire test or by calculation procedures.

Generator exhaust contains DEADLY carbon monoxide

gas. This dangerous gas can cause unconsciousness

or death. Do not place the unit near windows, doors,

fresh air intakes (furnaces, etc) or any openings in the

building or structure, including windows and doors of an

attached garage.

The air-cooled product line has under gone the required testing,

which meets the requirements of exception 2. The criteria for

the testing were to determine the worst-case fire scenario within

the Generator and to determine the ignitability of items outside

the engine enclosure at various distances. The enclosure is

constructed of non-combustible materials. The results and

conclusion from the independent testing lab indicated that any

fire within the Generator enclosure would not pose any ignition

risk to nearby combustibles or structures, with or without fire

service personnel response.

Based on the required testing, the requirement of NFPA 37,

Sect 4.1.4, the guidelines for the 8, 10, 12, 13, 14, 15, 16,

17 and 20kW units changed to 18 inches (457mm) from the

back side of the Generator to a stationary wall or building. For

adequate maintenance and airflow clearance, the area above

the Generator should be at least three (3) feet with a minimum

of three (3) feet at the front and ends of the enclosure. This

includes, but not limited to trees, shrubs, and vegetation that

could obstruct airflow. See Figures 1 and 6 for further details.

GROUNDING THE GENERATOR

The National Electric Code requires that the frame and external

electrically conductive parts of the Generator be properly

connected to an approved earth ground. Local electrical codes

may also require proper grounding of the unit. For that purpose,

a grounding lug is attached to the unit. Grounding may be

accomplished by attaching a stranded copper wire of the proper

size to the Generator grounding lug and to an earth-driven

copper or brass grounding-rod. Consult with local electrician

for grounding requirements in the area.

THE FUEL SUPPLY

Natural gas is the primary fuel source utilized for the operating,

testing and adjusting of units with air-cooled engine. When

it is necessary, it is possible to convert units with air-cooled

engines to use liquid propane vapor (LPV). See Section 1.4

“Reconfiguring the Fuel System” for the conversion procedure.

LPV gas is usually supplied as a liquid in high-pressure tanks.

The air-cooled product requires a “vapor withdrawal” type of

fuel supply system when Liquid Propane (LP) gas is used. The

“vapor withdrawal” system utilizes the gaseous fuel vapors that

form at the top of the supply tank.

The pressure at which LP is delivered to the Generator may

Loading...

Loading...