Section 2 - Post Installation Start-up and Adjustments

Air-cooJedGenerators

POS%_

iNSTALLATiON

STAR.UP

ADJUSTMENTS

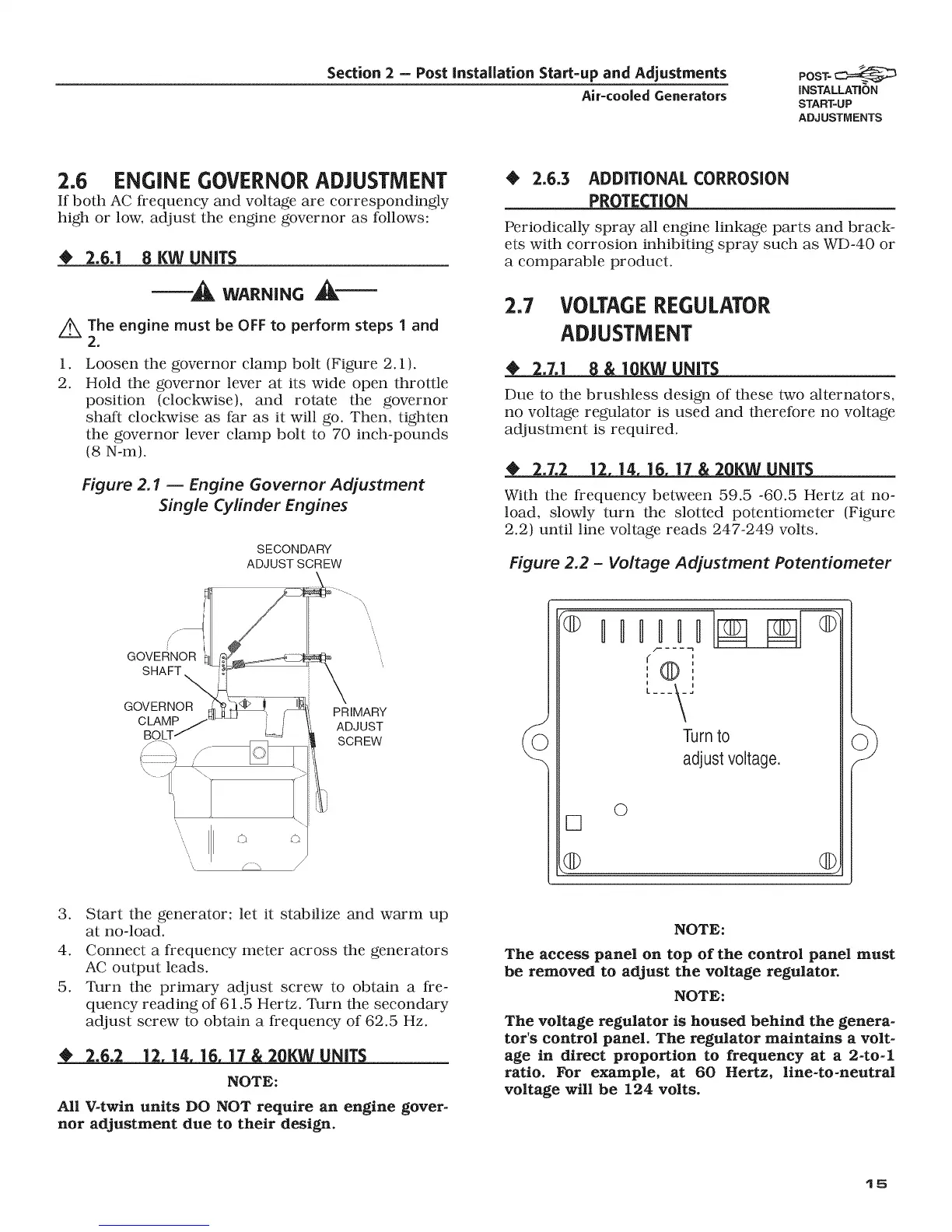

2.6 ENGINE GOVERNORADJUSTMENT

If both AC frequency and voltage are correspondingly

high or low, adjust the engine governor as follows:

• 2.6.1 8 KWUNITS

=_ WARNING

Z_ The engine must be OFF to perform steps I and

2.

1.

2.

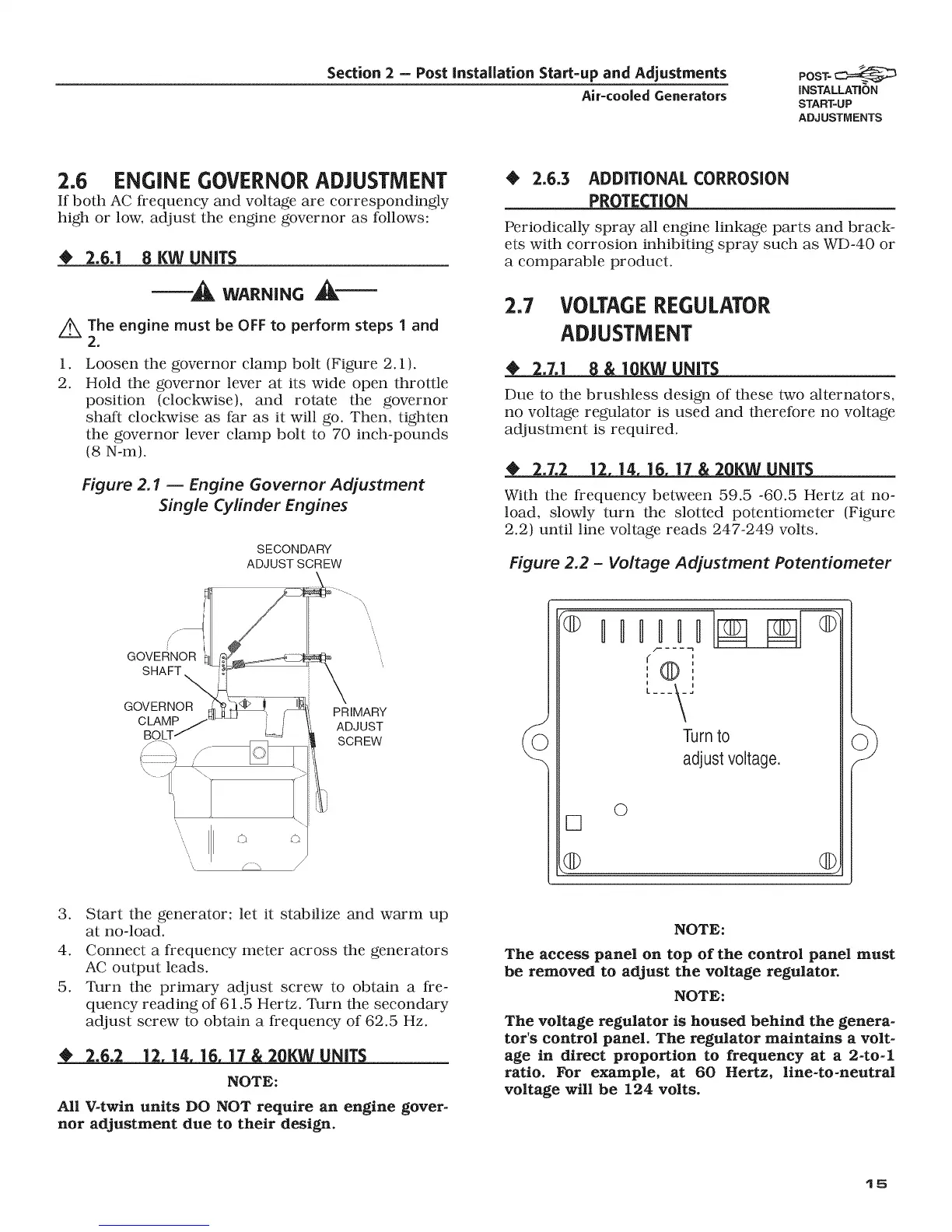

Loosen the governor clamp bolt (Figure 2.1).

Hold the governor lever at its wide open throttle

position (clockwise), and rotate the governor

shaft clockwise as far as it will go. Then, tighten

the governor lever clamp bolt to 70 inch-pounds

(8 N-m).

Figure 2.1 -- Engine Governor Adjustment

Single Cylinder Engines

SECONDARY

ADJUST SCREW

• 2,6,3 ADDiTiONAL CORROSION

PR_

Periodically spray all engine linkage parts and brack-

ets with corrosion inhibiting spray such as WD-40 or

a comparable product.

2.7 VOLTAGEREGULATOR

ADJUSTMENT

2.7,] 1 KW NiT

Due to the brushless design of these two alternators,

no voltage regulator is used and therefore no voltage

adjustment is required.

2.7.2 ]2 14 ] 17 2 KW NiT

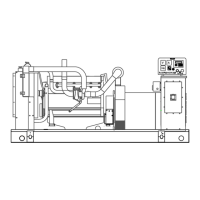

With the frequency between 59.5 -60.5 Hertz at no-

load, slowly turn the slotted potentiometer (Figure

2.2) until line voltage reads 247-249 volts.

Figure 2.2 - Voltage Adjustment Potentiometer

f"_ _'_

, /-o-_ \ /

i

[---_J

Turnto

adjust voltage.

O

[]

.@ Q

3. Start the generator; let it stabilize and warm up

at no-load.

4. Connect a frequency meter across the generators

AC output leads.

5. Turn the primary adjust screw to obtain a fre-

quency reading of 61.5 Hertz. Turn the secondary

adjust screw to obtain a frequency of 62.5 Hz.

2..2 ]2 14 ] ]7 2 KW NiT

NOTE:

All V-twin units DO NOT require an engine gover-

nor adjustment due to their design,

NOTE:

The access panel on top of the control panel must

be removed to adjust the voltage regulator.

NOTE:

The voltage regulator is housed behind the genera-

tot's control panel. The regulator maintains a volt-

age in direct proportion to frequency at a 2-to-I

ratio. For example, at 60 Hertz, line-to-neutral

voltage will be 124 volts.

15

Loading...

Loading...