9

10. Turn ON the STANDBY (EMERGENCY) power supply to the

transfer switch by whatever means provided (such as the

main line circuit breaker).

11. With the generator running, check that the STANDBY -

OPERATING LED on the switch enclosure door is ON.

12. With an accurate AC voltmeter, check phase-to phase (line-

to-line) and phase-to neutral (line-to neutral) voltages present

at transfer mechanism terminals E1, E2 and E3. Also check

AC frequency at those terminals. Generator AC output voltage

and frequency must be compatible with transfer switch rated

voltage and frequency.

DANGER

Ensure that the phase rotation of STANDBY

(GENERATOR) power lines and transfer switch

NORMAL (UTILITY) and load power lines are

compatible.

13. If supplied voltage or frequency is incorrect, refer to standby

generator Owner’s Manual. If AC frequency is incorrect,

adjust engine governed speed. If voltage is incorrect, adjust

generator’s voltage regulator or correct the problem.

14. When supplied voltage and frequency is correct, shut down

the engine manually.

DANGER

Supplied voltages from both NORMAL (UTILITY)

and STANDBY (EMERGENCY) power sources

must be compatible with transfer switch rated

voltage before proceeding.

15. Connect the transfer switch load to the transfer switch when

“voltage checks” section has been completed. Connect the

load to the transfer switch by whatever means provided (such

as circuit breaker(s)), then proceed with the “ELECTRICAL

OPERATION” section.

3.4 ELECTRICAL OPERATION

Test transfer system electrical operation as follows:

1. On the enclosure door, check that the UTILITY AVAILABLE

LED is ON.

2. On the enclosure door, check that the SWITCH POSITION-

UTILITY LED is ON.

The UTILITY AVAILABLE LED and the SWITCH

POSITION-UTILITY LED (on enclosure door)

must both be ON before proceeding to Step 3.

3. Refer to the appropriate owner’s manual. Be sure the standby

generator is prepared for automatic operation.

4. In the switch enclosure, set the Maintenance Disconnect

switch to AUTOMATIC.

5. Press the “TEST” button on the enclosure door. Generator

startup and transfer to the STANDBY power source should

occur. Refer to the “Sequence of Operation” section.

6. Press the “TEST” button again to initiate the retransfer

sequence. The customer LOAD will be transferred back to the

UTILITY power source, using the preset times. The generator

will shut down once the engine cool down timer has expired.

3.5 TRANSFER MECHANISM

The transfer mechanism houses the main, current carrying con-

tacts, along with other mechanical and electrical components,

required for operating the switch. The main contacts are electri-

cally operated and mechanically latched in place.

Power for the closing, selective and trip coil is taken from the

source of supply that the Customer Load is being transferred to.

Therefore, transfer to any power source cannot occur unless that

power source is available to the switch.

Customer Load contacts are bolted to an insulated plastic pole

piece and are stationary. The UTILITY (NORMAL) and GENERATOR

(EMERGENCY) contacts are moveable.

3.6 TRANSFER MECHANISM

OPERATION

There are three (3) coils inside a "WN" switch that are used in

transferring power to the respective load;

Closing Coil - When energized, closes the main contacts on •

Utility or Generator side, depending on if the select coil is

energized or not.

Select Coil - When energized, the mechanism is configured to •

close the Generator supply contacts when the closing coil is

energized.

Trip Coil - When energized, the main contact latch is released •

and the contacts move to the open position by spring tension.

All 3 solenoids are only energized momentarily.

Refer to the diagnostic repair manual 079247, section 9.6 for

complete operational analysis.

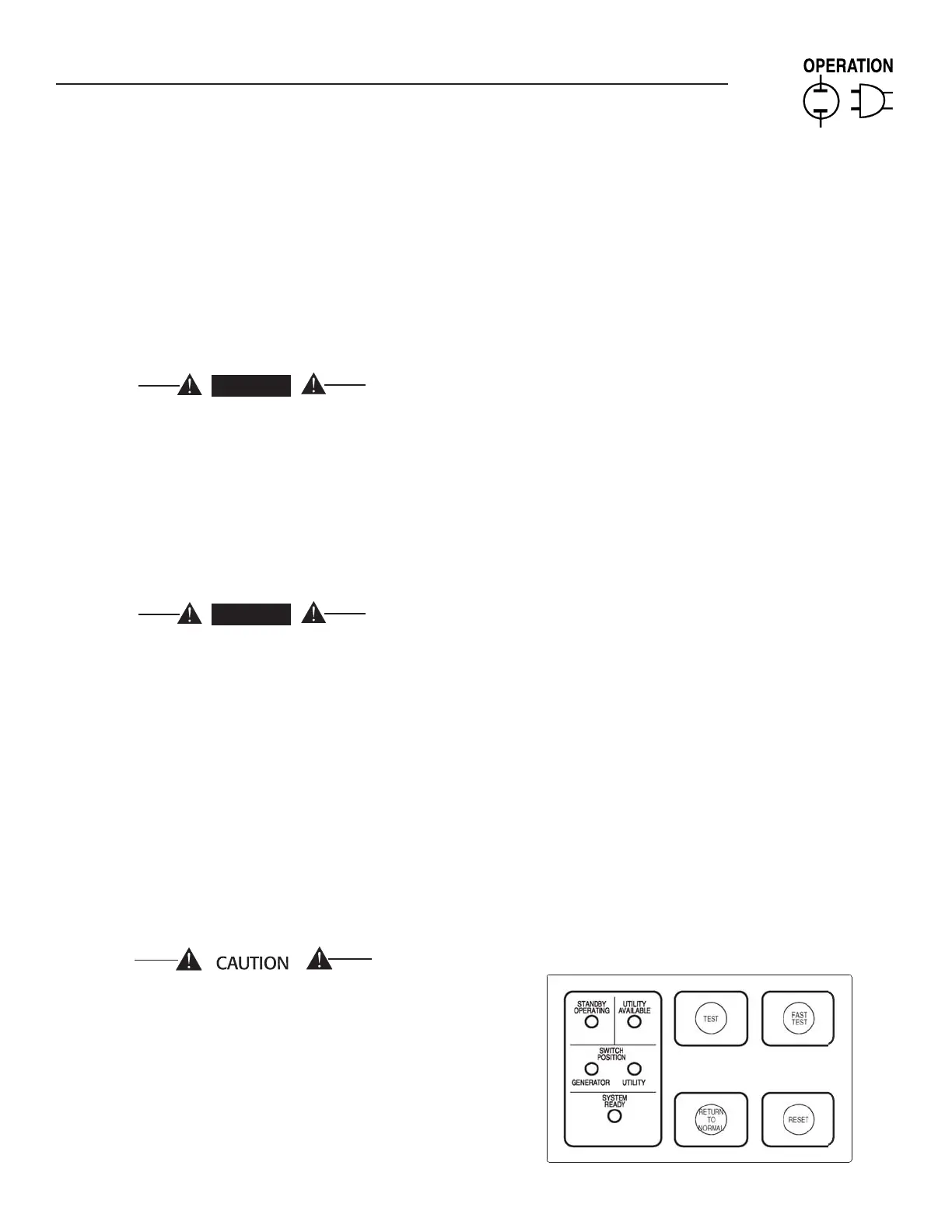

3.7 SWITCHES AND INDICATORS

This section will familiarize the reader with switches and indicators

on the membrane switch panel mounted on the enclosure door,

as well as the Maintenance Disconnect switch inside the switch

enclosure. See Figure 3.2.

Figure 3.2 — OTTS Switch

Section 3 — Operation

HTS “Wn” Type Transfer Switch

Loading...

Loading...