WHEN THE CO PERCENTAGE IS RIGHT AND THE CO2 PERCENTAGE DOES NOT FALL INTO

THE SPECIFIED VALUES, THE LAMBDA VALUE IS ALSO DISTORTED. IF THIS OCCURS, CARE-

FULLY CHECK THE EXHAUST SYSTEM FOR ADEQUATE SEALING.

When the CO percentage is correct and the HC (PPM) value exceeds the maximum limit allowed, check:

- spark plug

- valve clearance

- timing system phase

- outlet valves for sealing

When the control unit is replaced, reset TPS and pre-program the trimmer value of the original control

unit (if available) preventively.

In any case, check the CO value again.

N.B.

WHEN THE CO PERCENTAGE IS RIGHT AND THE CO2 PERCENTAGE DOES NOT FALL INTO

THE SPECIFIED VALUES, THE LAMBDA VALUE IS ALSO DISTORTED.

If this occurs, carefully check the exhaust system for adequate sealing.

When the CO percentage is correct and the HC (PPM) value exceeds the maximum limit allowed, check:

- spark plug

- valve clearance

- timing system phase

- outlet valves for sealing

When the control unit is replaced, reset TPS and pre-program the trimmer value of the original control

unit (if available) preventively.

In any case, check the CO value again.

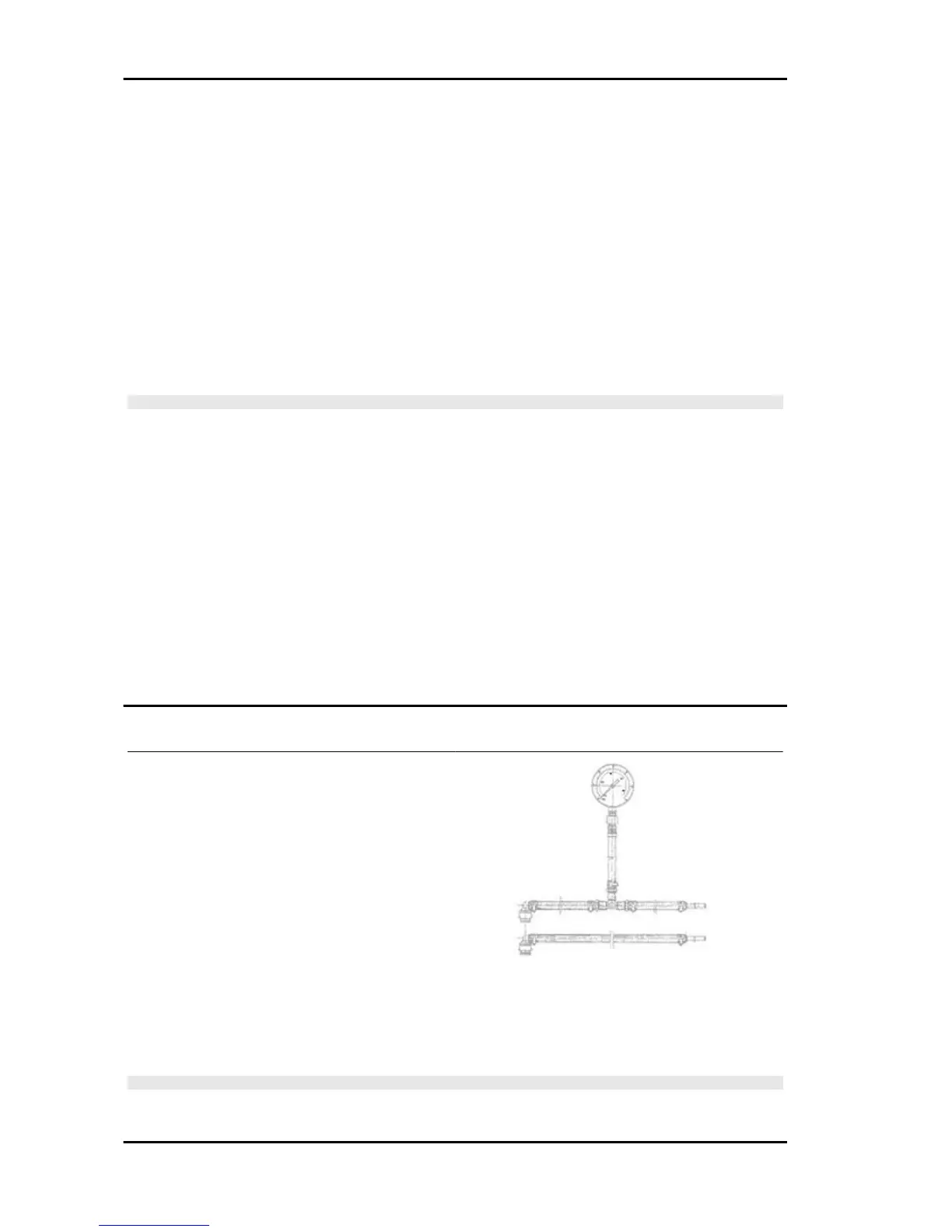

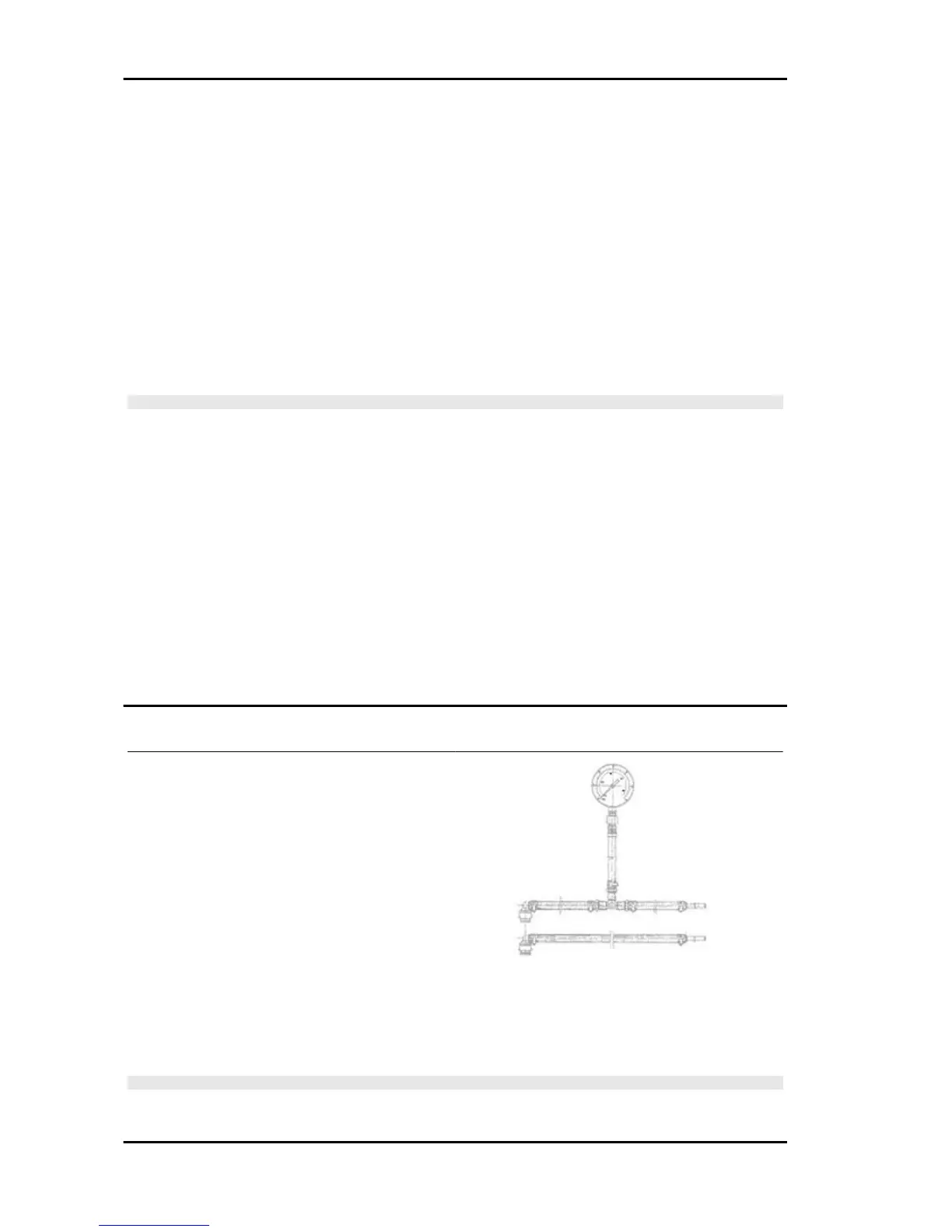

Circuit leak test

Before performing the checks concerning the sys-

tem pressure, it is necessary to carefully clean all

feeding system components.

To perform the inspections it is necessary to use

the special tooling kit for fuel pressure check.

Specific tooling

020480Y Petrol pressure check set

Before disconnecting any fastener, reduce the system pressure.

Detach the electrical connector from the pump support with the engine running, and wait for the shut-

down.

The engine stops at approximately 1.5 bar.

CAUTION

CAREFULLY DETACH THE HOSE TERMINAL PREVENT ANY POSSIBLE SPRAYING INTO THE

EYES.

Injection Nexus 500 euro 3

INJEC - 222

Loading...

Loading...