3534

ASPEC® POSITIVE PRESSURE MANIFOLD | User's GUideUSER’S GUIDE | ASPEC™ POSITIVE PRESSURE MANIFOLD

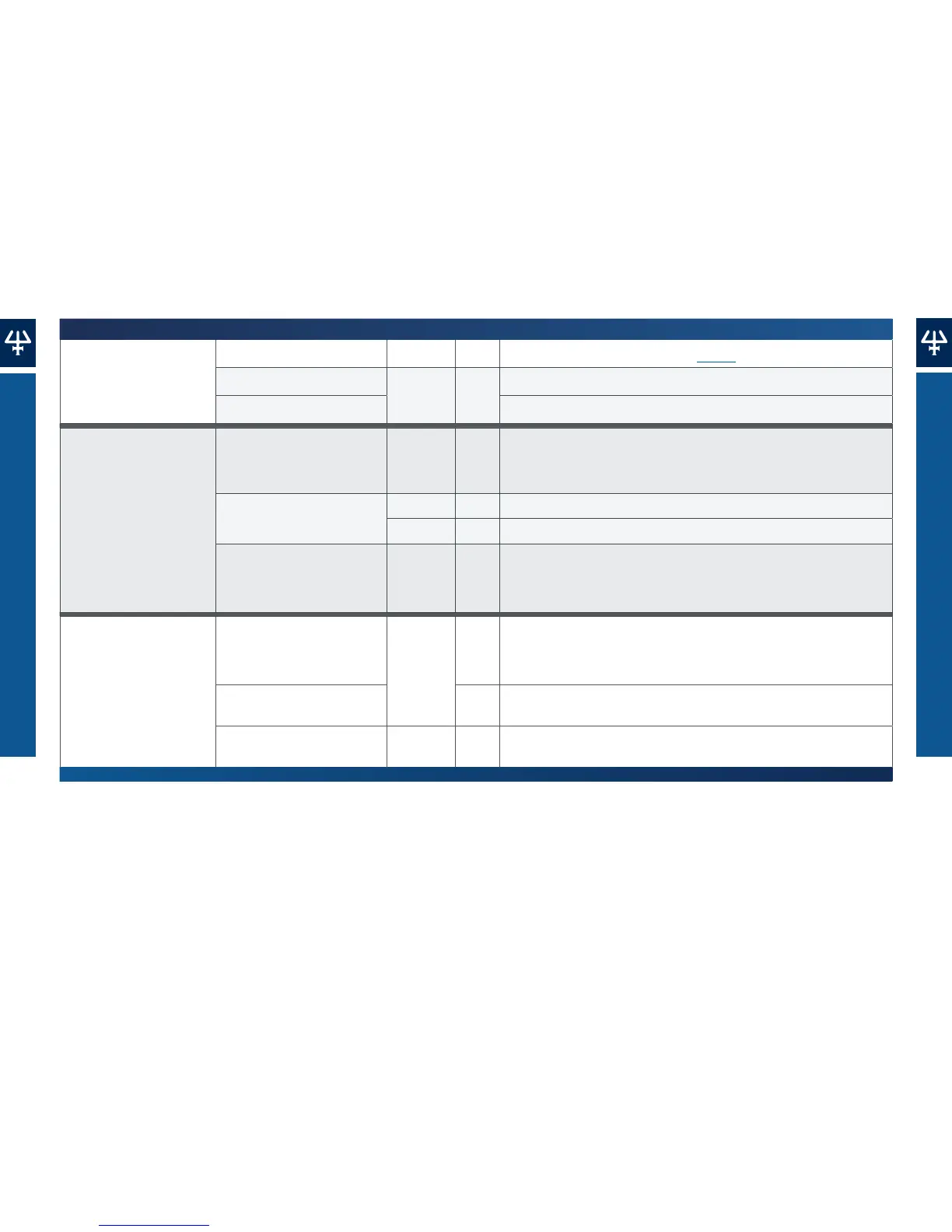

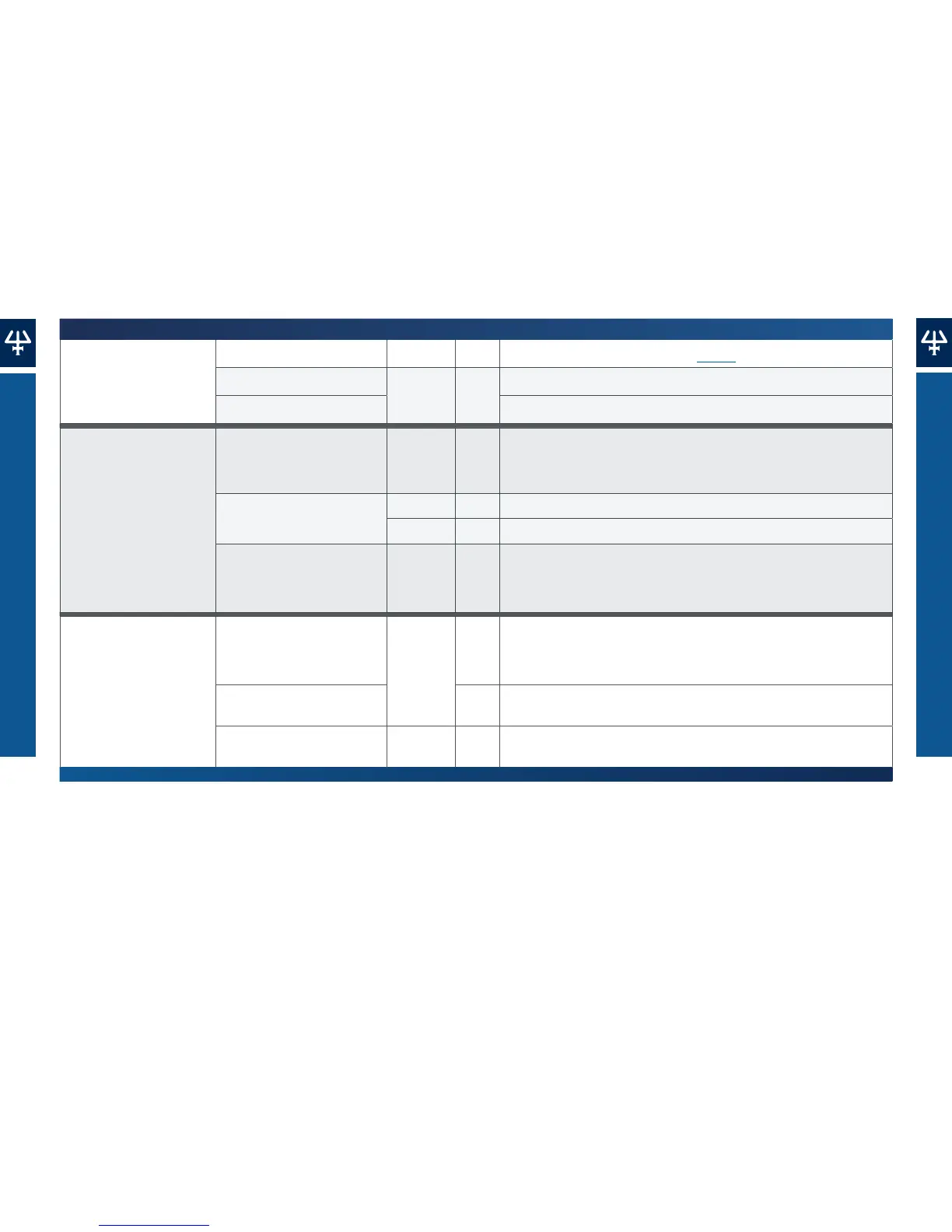

TroUbleshooTinG Table

TroUbleshooTinG Table

Symptoms Possible Causes SPE Steps Solutions

Contamination

Previous samples overflowed. Load Replace the manifold gasket. Refer to page 31.

Unclean collection tubes.

Elution

Replace the collection vessels.

Elution solvent splashed. Reduce the elution flow rate.

Lower recoveries than

usual for an optimized SPE

protocol.

SPE cartridge packing

material dried.

Condition

When the liquid level on the fastest eluting SPE cartridge reaches

2mm above the top frit (High Flow), switch to the SPE control dial to

Low Flow, and then slowly turn the low flow adjustment knob clockwise

until flow restarts and the liquid level equilibrates for all cartridges.

Not enough time for

extraction to be completed.

Load Decrease the flow rate to better extract analytes from the sample matrices.

Elution Decrease the flow rate to better extract analytes from the solid phase.

Residual trace of the washing

solvent inside the packing

material of the SPE cartridge/s

prior to the elution step.

Wash

Switch the process control dial to Dry after the last washing step for

several minutes.

Fewer interferents

removed than usual for an

optimized SPE protocol.

Residual trace of the washing

solvent inside the packing

material of the SPE cartridge/s

prior to the elution step.

Wash

Turn the process control dial to Dry after the last wash step. Thoroughly dry

the SPE cartridges for several minutes.

Not enough time to remove

interferents.

Decrease flow rate.

A new batch of

SPEcartridges.

Elution Replace the SPE cartridges with a new batch.

Loading...

Loading...