3332

ASPEC® POSITIVE PRESSURE MANIFOLD | User's GUideUSER’S GUIDE | ASPEC™ POSITIVE PRESSURE MANIFOLD

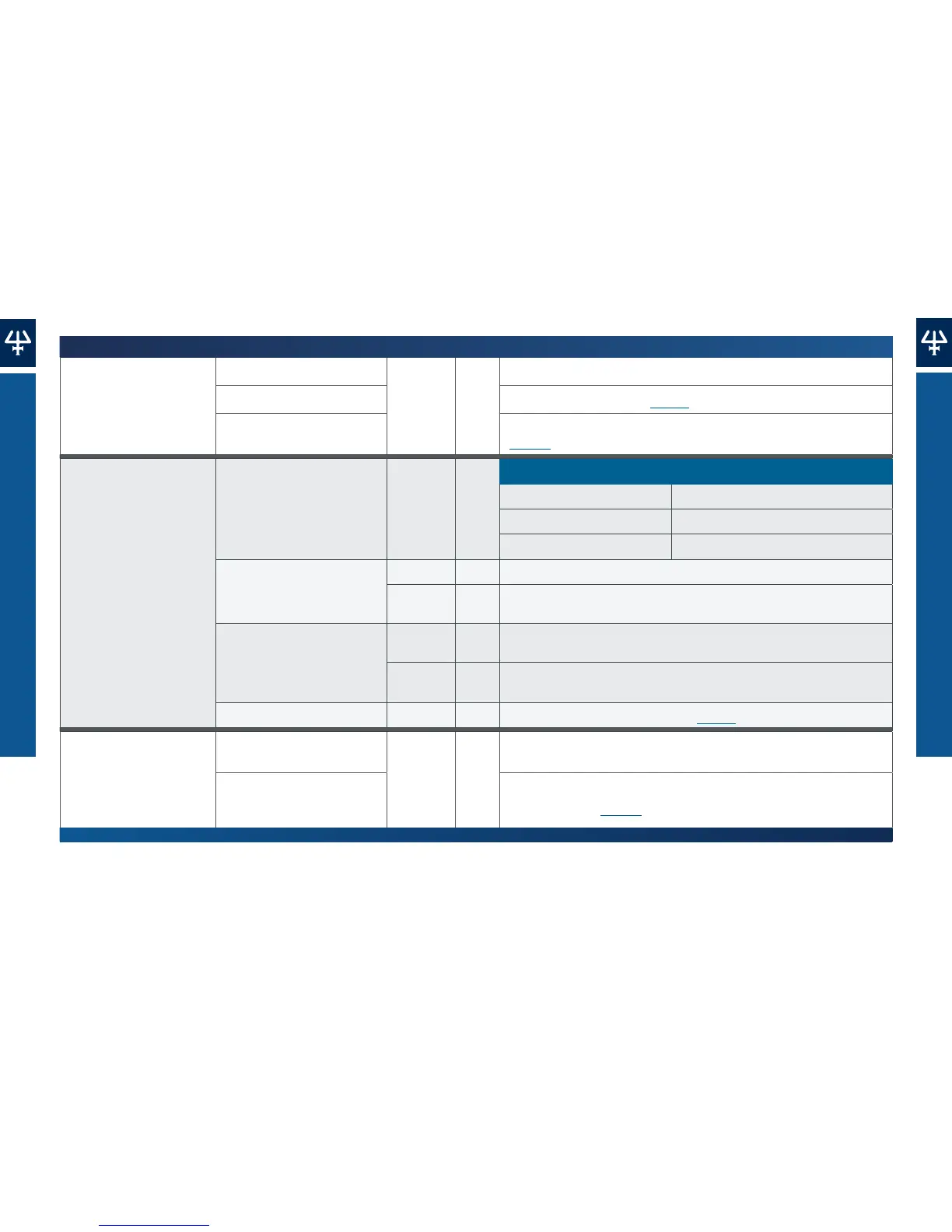

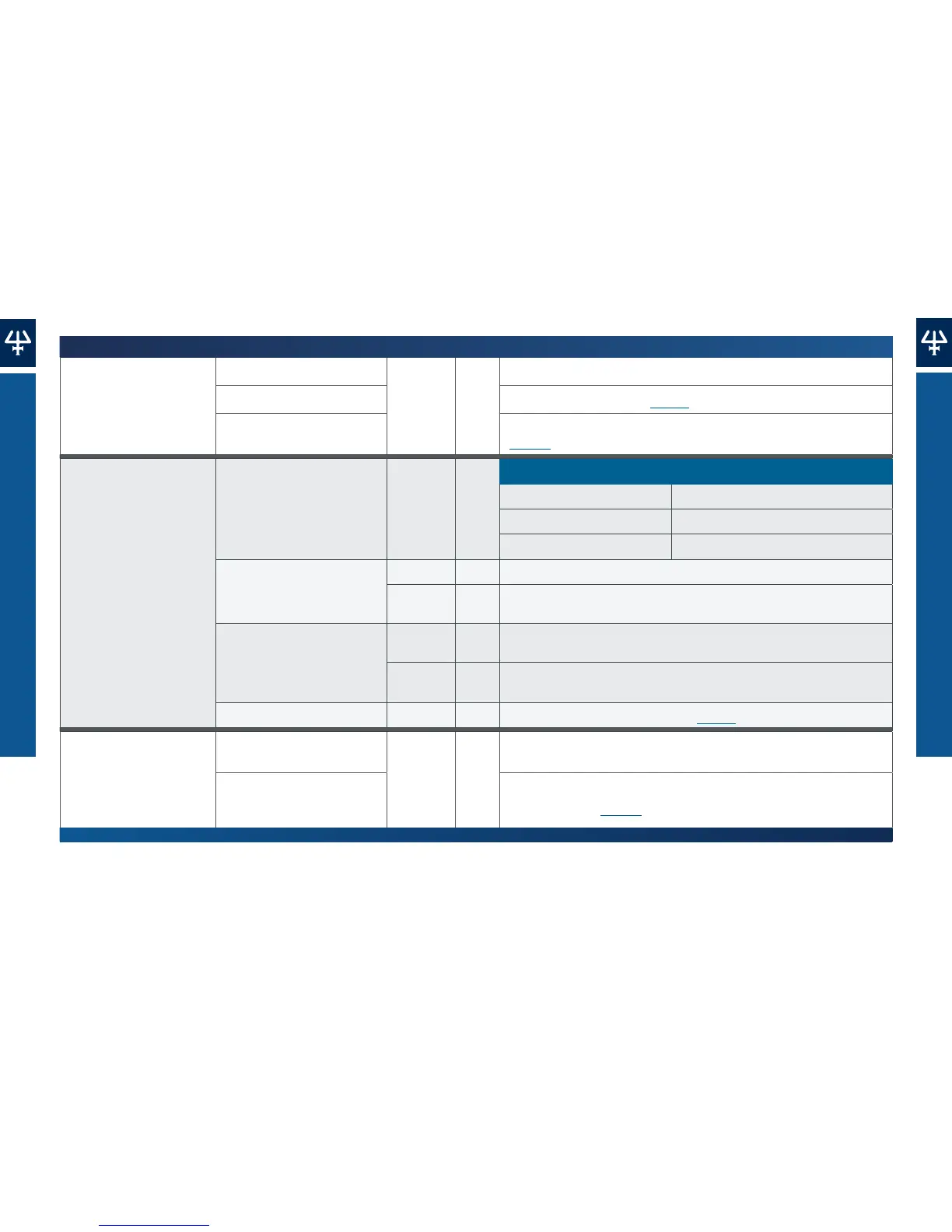

TroUbleshooTinG Table

TroUbleshooTinG Table

Troubleshooting Table

Symptoms Possible Causes SPE Steps Solutions

Lack of flow

No inlet pressure.

All

Check that the gas pressure source is set to 15 psi.

O-ring damaged or missing. Replace the O-ring. Refer to page 31.

Damaged process control dial.

Replace the front panel. Contact your local Gilson representative. Refer to

page 36.

Liquid flows unevenly

Channeling inside the sorbent

of the SPE cartridge/s.

Condition

Specific Causes Specific Solutions

Drying of the cartridge/s. Repeat the condition step.

Insucient condition volume. Increase the condition volume.

Excessive flow rate. Reduce the flow rate.

Clogged SPE cartridge/s.

Condition Replace the SPE cartridge/s.

Load

Reconsider the sample preparation workflow; e.g., sample filtration,

centrifugation, etc.

Heterogeneous viscosity

inside the SPE cartridge/s,

caused by the use of

dierent liquids in successive

SPEsteps.

Condition

Reduce the residual level of liquid above the frit to 1 to 2mm before

conditioning with another type of liquid.

Wash and

Elute

Before using a new solvent, ensure that all euent has been expelled from

the SPE cartridges.

Leak in the manifold gasket. All Replace the manifold gasket. Refer to page 31.

Liquid continues to flow,

even after the SPE control

dial has been set to O.

The process control dial is set

to Dry.

All

Switch the process control dial to SPE.

Residual positive

pressure remains in the

SPEcartridge/s.

Switch the SPE control dial to Low Flow before stopping. Unseat the

manifold. Refer to page 24.

Loading...

Loading...