Start-up 9

0020289288_02 MicraCom Installation and maintenance instructions 27

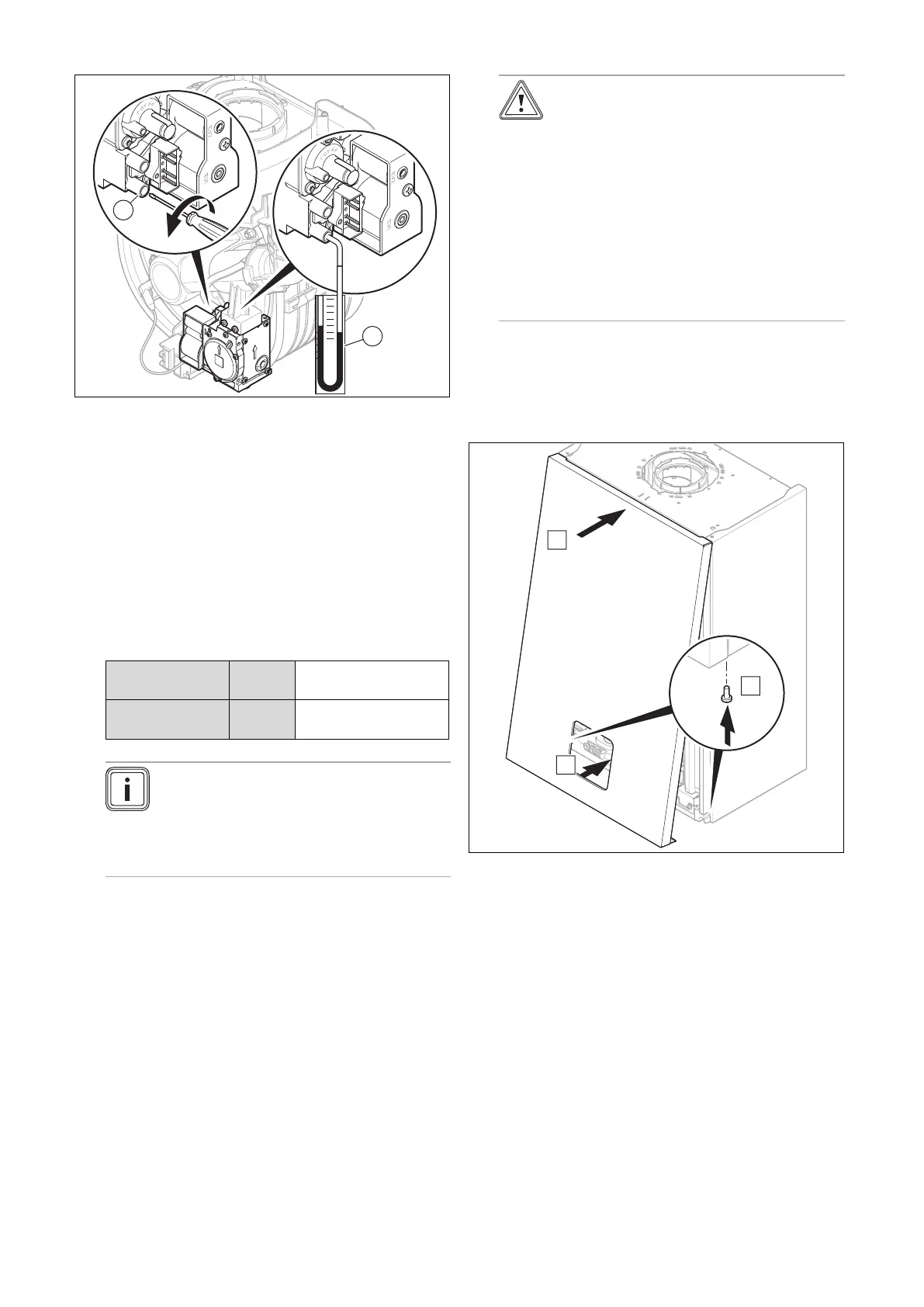

3. Turn the screw on the gas pressure measuring point (1)

anti-clockwise.

– Anti-clockwise (↺): Two rotations

4. Connect a manometer (2) to the test nipple (1).

– Working materials: U tube manometer

– Working materials: Digital pressure gauge

5. Hinge the electronics box upwards.

6. Open the gas stopcock.

7. Start up the product with check programme P.01.

(→ Page 24)

8. Measure the gas connection pressure/gas flow pres-

sure against the atmospheric pressure.

Permissible connection pressure

Great

Bri-

tain

Natural gas H

1.7 to 2.5 kPa

(17.0 to 25.0 mbar)

Liquefied petro-

leum gas

P

2.5 to 4.5 kPa

(25.0 to 45.0 mbar)

Note

The connection pressure is measured at the

gas valve assembly, meaning that the per-

missible minimum value may be 0.1 kPa (1

mbar) lower than the minimum value spe-

cified in the table.

Result 1:

Gas connection pressure/gas flow pressure in the per-

missible range

▶ Temporarily decommission the product. (→ Page 39)

▶ Hinge the electronics box downwards.

▶ Remove the manometer.

▶ Tighten the screw on the test nipple.

▶ Open the gas stopcock.

▶ Check the test nipple for gas tightness.

▶ Hinge the electronics box upwards.

▶ Install the front casing. (→ Page 27)

▶ Start up the product.

Result 2:

Gas connection pressure/gas flow pressure not in the

permissible range

Caution.

Risk of material damage and oper-

ating faults caused by incorrect gas

connection pressure/gas flow pres-

sure.

If the gas connection pressure/gas flow

pressure lies outside the permissible

range, this can cause operating faults

in and damage to the product.

▶ Do not make any adjustments to the

product.

▶ Do not start up the product.

▶ If you are unable to eliminate the fault, contact the

gas supply company.

▶ Close the gas stopcock.

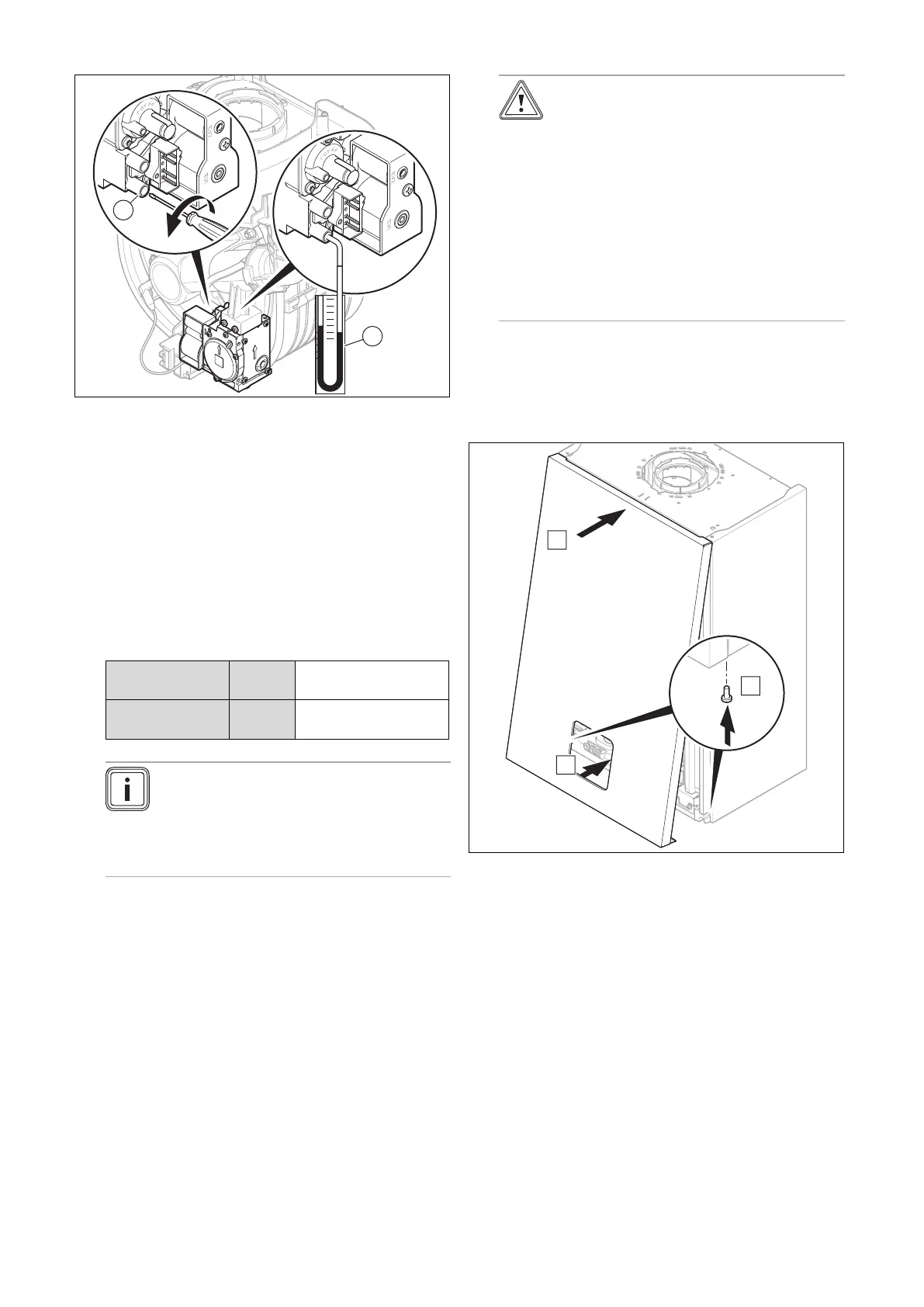

9.6.5 Installing the front casing

Loading...

Loading...