5 Installation

12 Installation and maintenance instructions SUSTAIN ..c 0020200954_00

5 Installation

5.1 Preparing for installation

Danger!

Risk of scalding and/or damage due to

incorrect installation leading to escaping

water.

Stresses in the supply line can cause leaks.

▶ Make sure there is no voltage in the sup-

ply lines when they are installed.

Caution.

Risk of damage caused by corrosion.

If non-diffusion-tight plastic pipes are used in

the heating installation, this may cause air to

enter the heating water and corrosion of the

heat generation circuit and the boiler.

▶ If using non-diffusion-tight plastic pipes

in the heating installation, separate the

system by installing an external heat ex-

changer between the boiler and the heat-

ing installation.

Caution.

Risk of material damage due to heat trans-

fer during soldering.

▶ Do not solder the connection pieces if

the connection pieces are screwed to the

service valves.

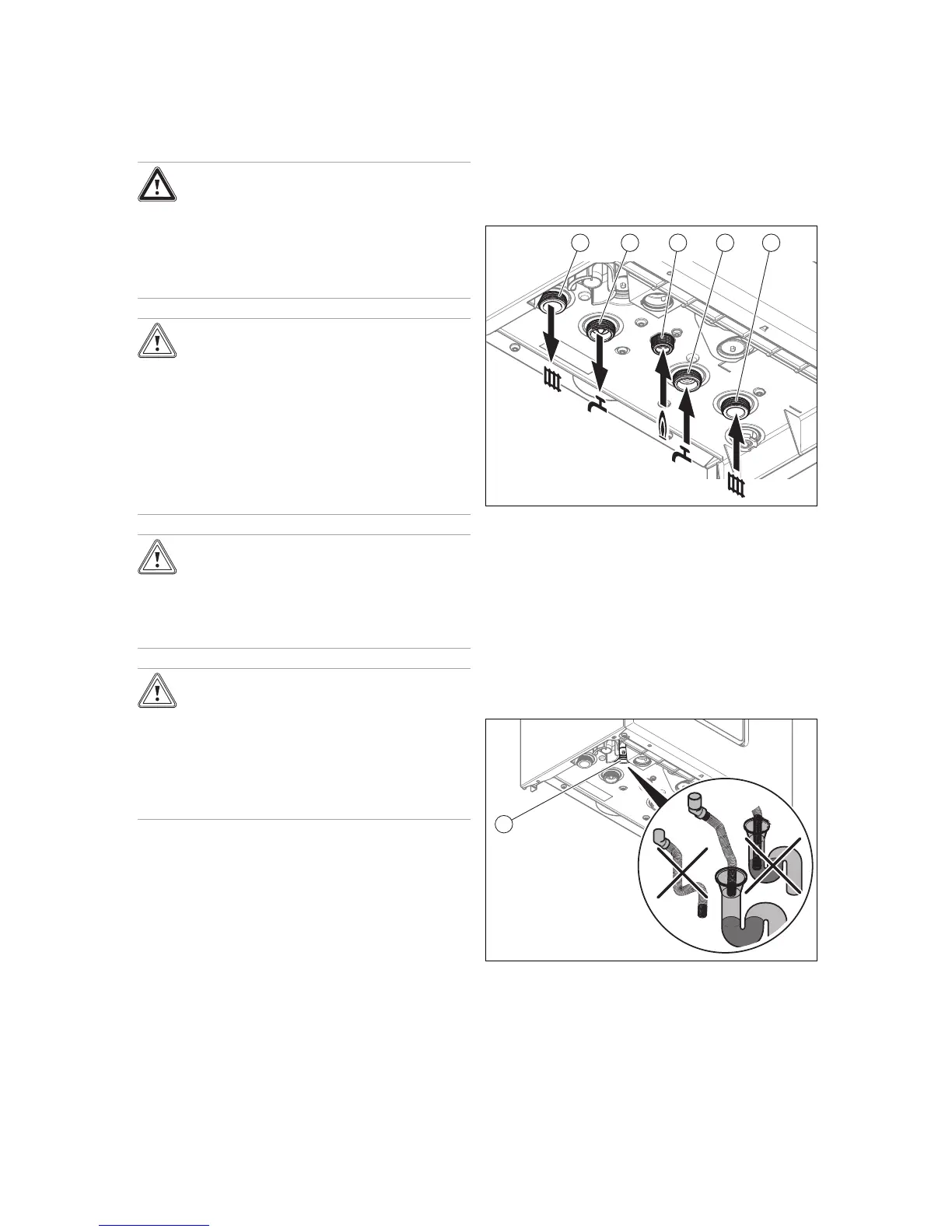

Caution.

Risk of damage caused by incorrect gas

installation.

Excess test pressure or operating pressure

may cause damage to the gas valve.

▶ Check the leak-tightness of the gas valve

using a maximum pressure of 1.1 kPa

(110 mbar).

▶ Flush the heating installation thoroughly prior to installa-

tion.

▶ Check that the volumetric capacity of the expansion ves-

sel is sufficient for the system volume.

▶ If the volume of the expansion vessel is insufficient, in-

stall an additional expansion vessel, connected as close

to the product as possible, in the heating return.

▶ If you are installing an external expansion vessel, either

fit a non-return valve in the product outlet (heating flow)

or decommission the internal expansion vessel. Other-

wise, the warm start function may be more frequently ac-

tivated because of backflow, which causes unnecessary

energy loss.

▶ Make sure that the existing gas meter is capable of

passing the rate of gas supply required.

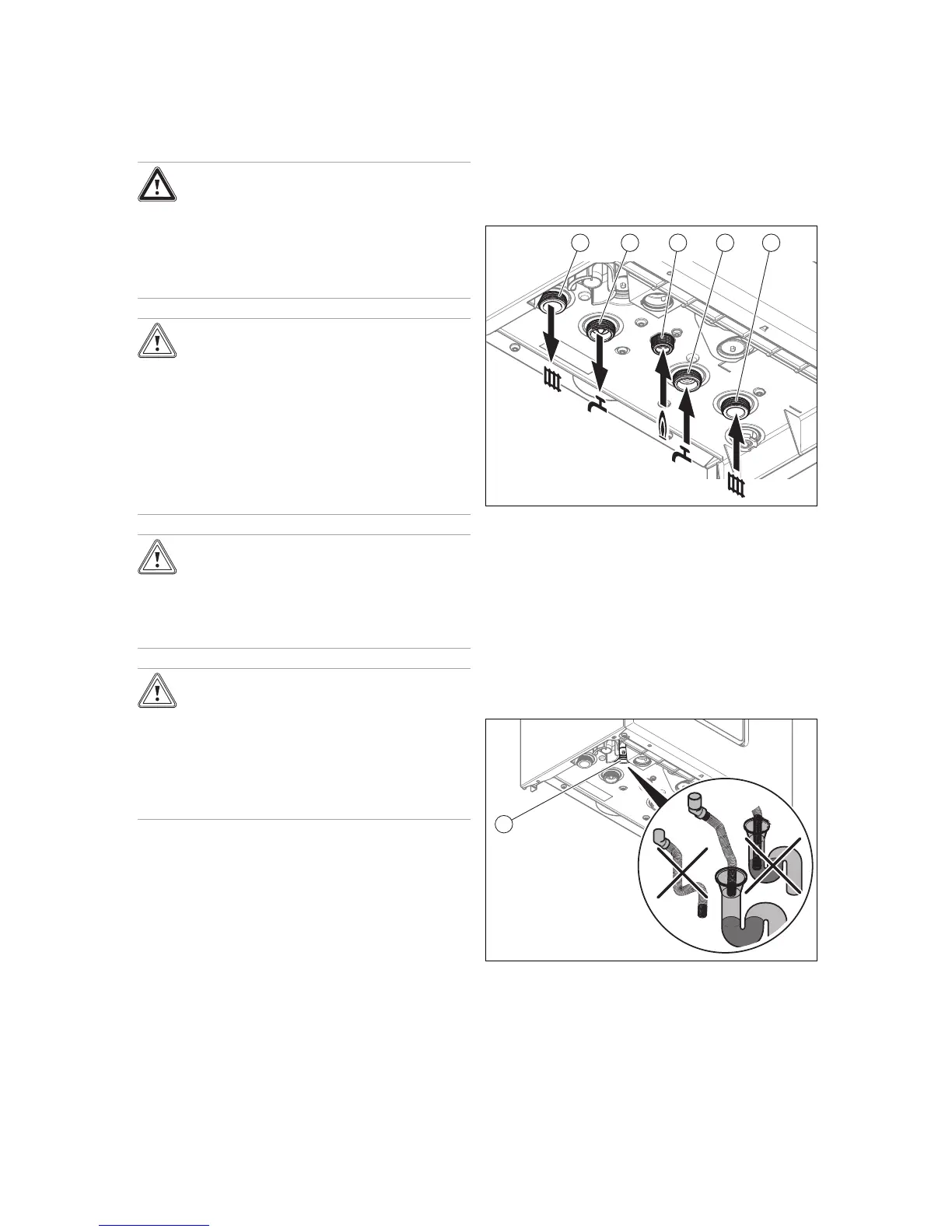

▶ Install the following components:

– A hot water safety group and a stop cock on the cold

water connection

– A filling device between the cold water connection

and the heating return

– A stop cock in the gas line

5.2 Gas and water connections

Loading...

Loading...