To help prevent injury from solvents and heated

fluids, wear gloves when using solvents and/or if the

fluid temperature exceeds 110 °F (43 °C).

Dispensing and Spraying

3A0590R 23

Flushing

• Ensure flushing fluid is compatible with dispense

fluid and the equipment wetted parts.

• Use a solvent that dissolves the material you are

mixin

g

• Solvent may channel through viscous fluids and

le

ave a coating of mixed fluid on the inner tube of

your hose. Make sure all fluid is thoroughly flushed

from the hose after each use.

• Remove spray tip for more thor

ough cleaning of the

whip hose and static mixers.

• Always leave equipment filled with fluid to avoid

d

rying and scaling.

• Frequently remove, clean and replace the static

mixe

r elements.

1. Follow the Pressure Relief Procedure on page 21.

2. Remove the spray tip and soak in solvent.

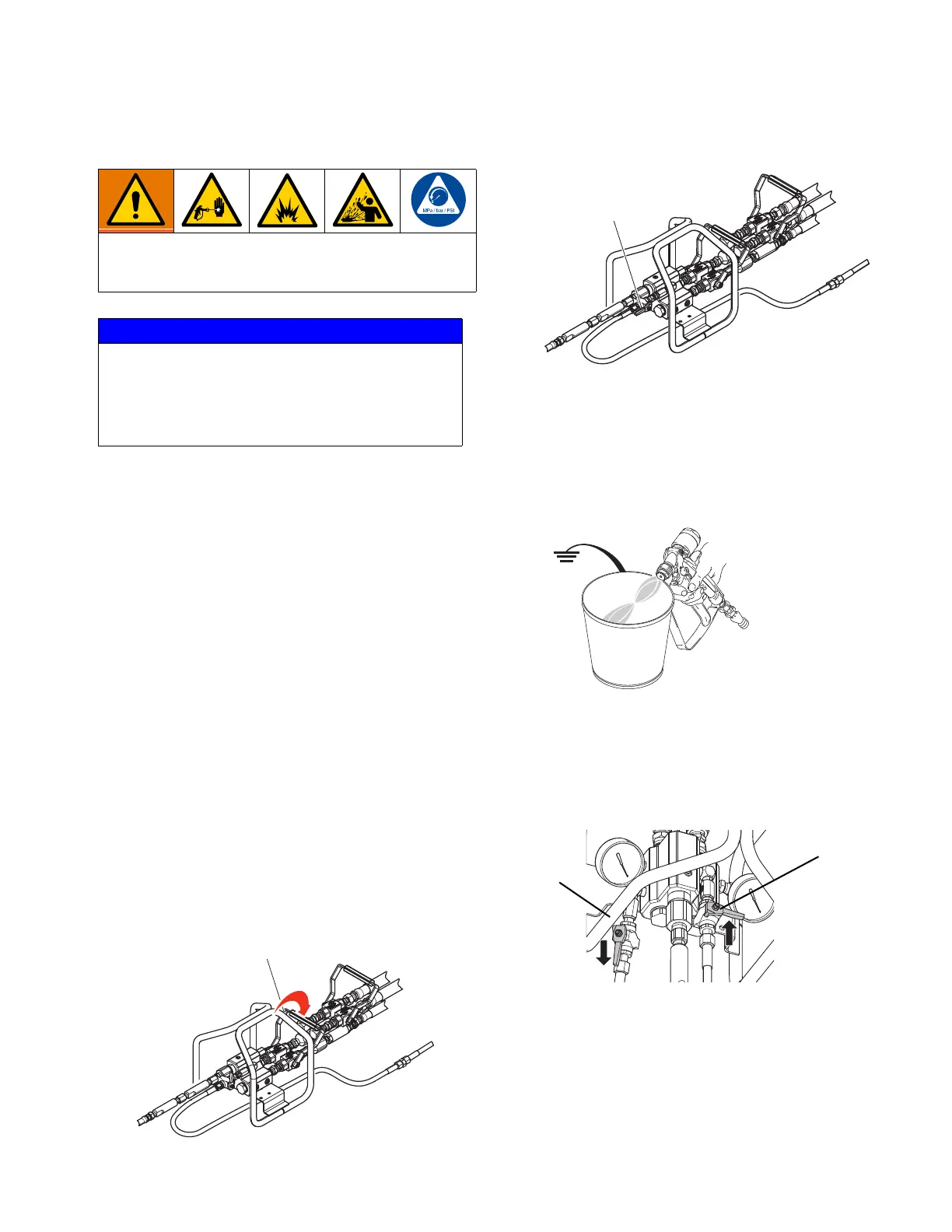

3. Close the dual shutoff handle (AE).

4. Open the shutoff valve (AG). For the Quickset

ma

nifold, close the A side flush valve (DE).

5. Turn on solvent flush pump.

6.

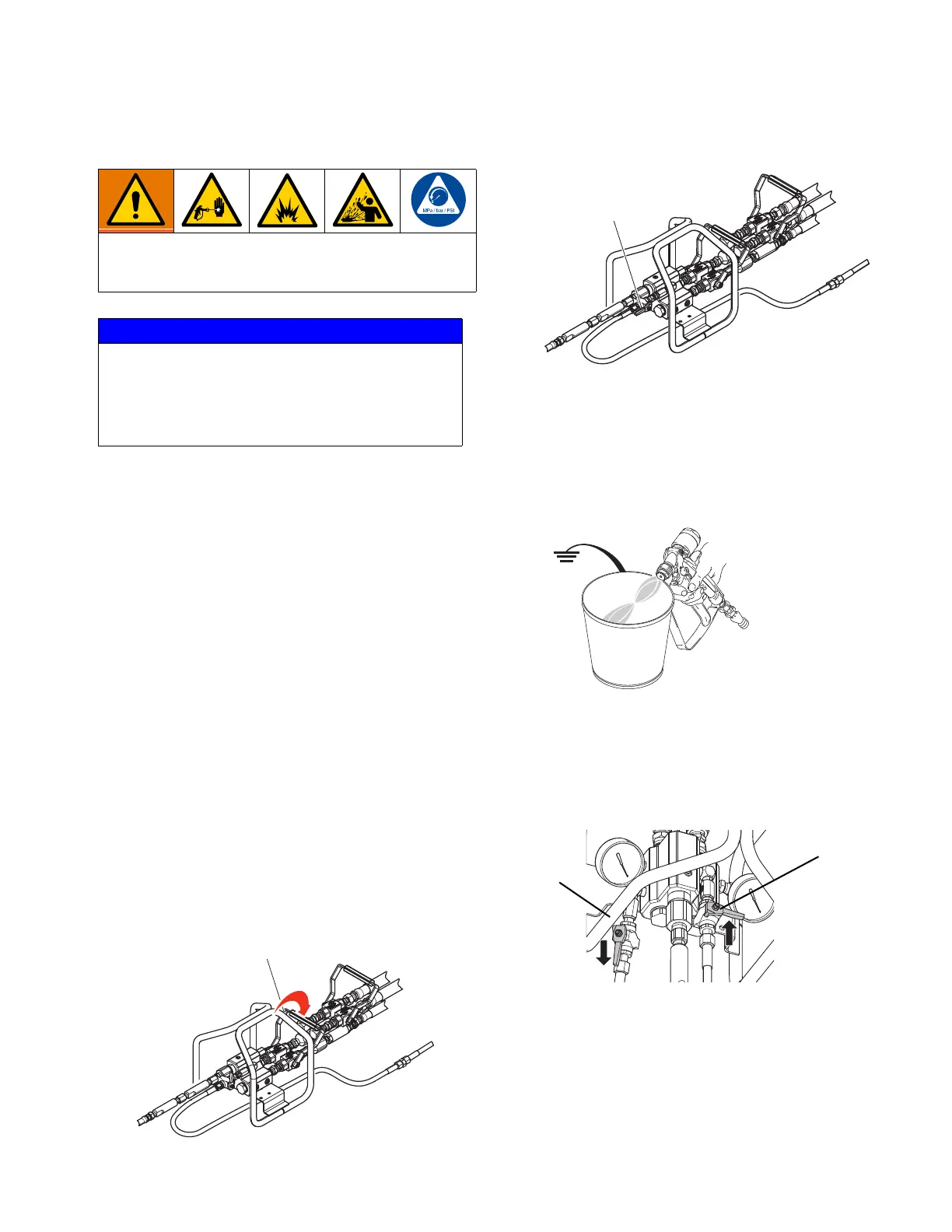

Disengage spray gun trigger lock.

7. Trigger the gun into a grounded metal pail with lid.

Use a lid with a hole to dispense through to avoid

splashing. Trigger the gun until clean solvent

dispenses.

a. For the standard mix manifold, proceed to step

8.

b.

For the Quickset mix manifold, after briefly

flushing with the B side valve, close the B side

flush valve (DC) and open the A side flush valve

(DE). Repeat step 7 until clean.

8. Turn off the solvent pump air assembly.

9. Hold the metal part of the gun firmly to a grounded

metal pail with the lid in place. Trigger the gun until

all fluid pressure is relieved.

NOTICE

To prevent damage to the valve balls and seats,

always fully open or fully close the dual shutoff

handle. Also increase the fluid pressure after

opening the ball valves to allow valves to last

longer.

Loading...

Loading...