Volume Balancing the Mix Manifold

3A0590R 25

Use Table 2 and the examples provided to approximate

how much pressure drop you can expect for every 50 ft

(15.2 m) of hose at 1 gpm flow in that particular hose for

a 1000 cps viscosity material. Adjust for your

applications flow rate and viscosity.

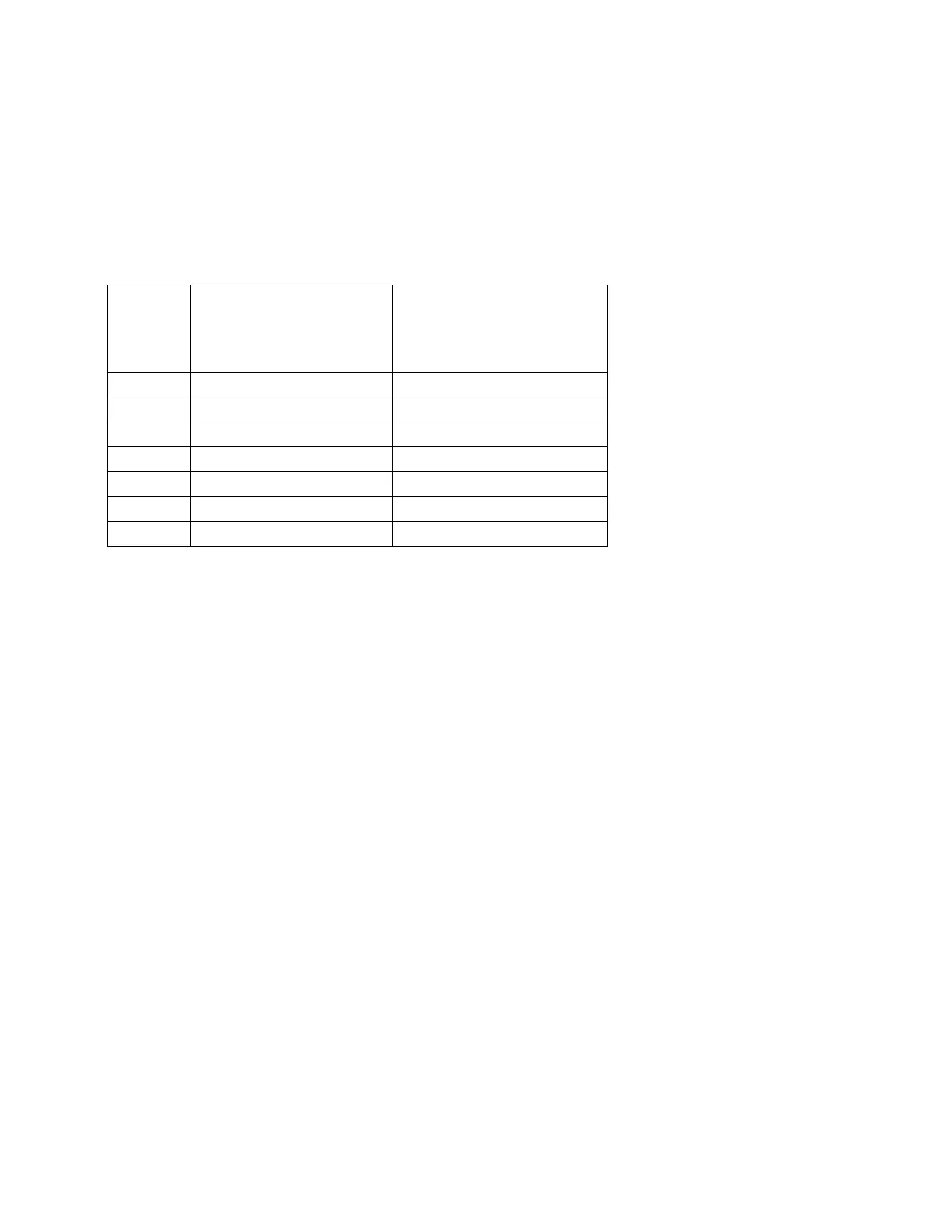

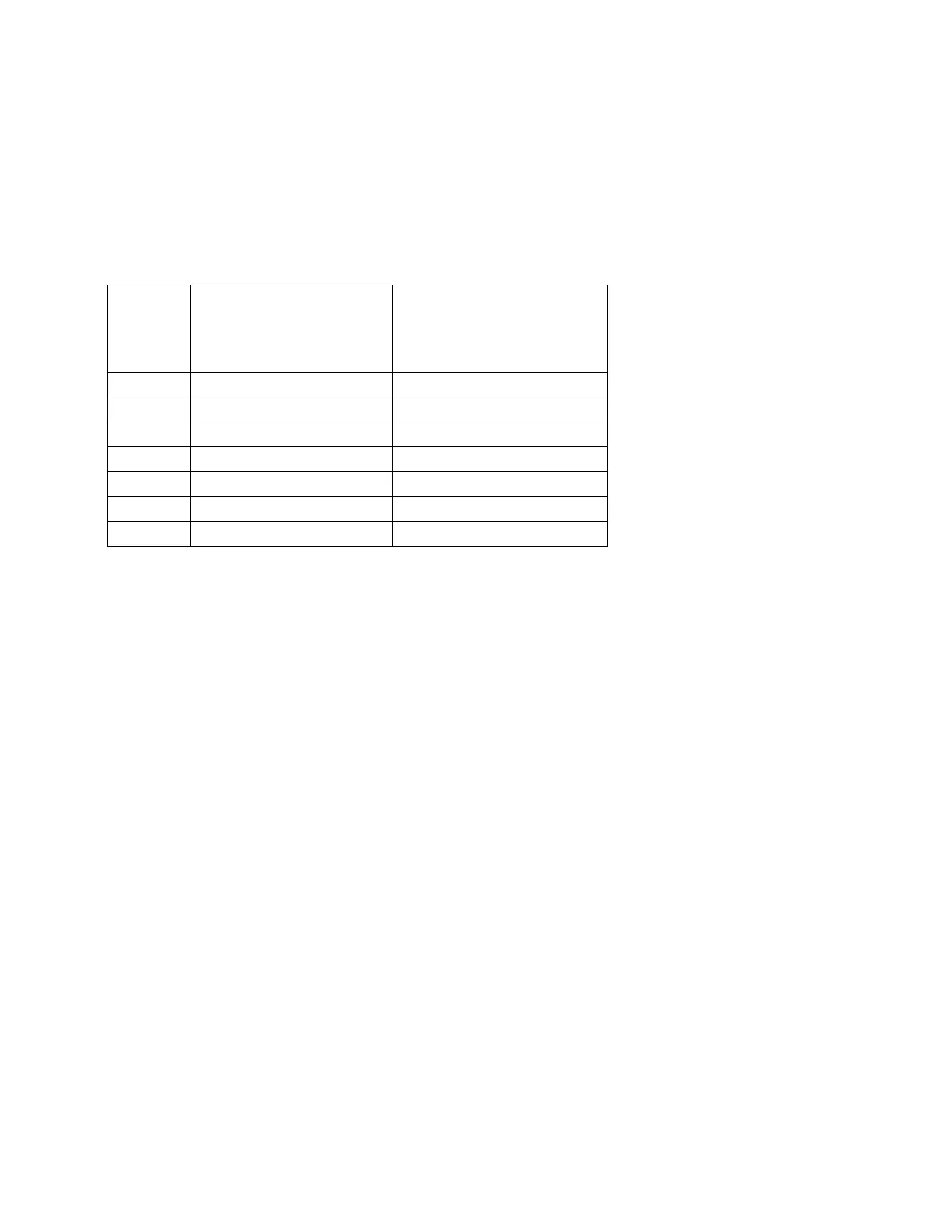

Table 2: Hose Selection by Pressure Drop

Hose ID

(in.)

Pressure drop per 50 ft

section per 1000 cps at 1

gal/min.

(psi)

Pressure Drop per 15.24

meter section per 1000

cps at 1 liter/min.

(Bar)

1/8 55910 1018

3/16 11044 201

1/4 3494 64

3/8 690 13

1/2 218 4

5/8 89 1.62

3/4 43 0.78

Reference Formula

Pressure drop = 0.0273 QVL/D

4

Key:

Q = Vis poise (centipoise/100)

V= Gallons per minute

L= Length (ft)

D=Inside diameter (in.)

Typical flow rates are usually 0.4-0.8 gpm (1.5-3

l/mn) per gun depending on tip size and viscosity.

Example 1: Wha

t is the pressure loss of a 2000 cps

material through 150 ft of 3/8 in. ID hose at 0.75 gpm?

690 psi (from chart) x 2 (viscosity factor 2 x 1000 cps) x

3

(3 x 50 ft hoses) x 0.75 (% of gpm) = 3105 psi loss

That is a lot of pressure loss before the spray gun. Try a

1/

2 in. hose. See Example 2.

Example 2: Wha

t is the pressure loss of a 2000 cps

material through 150 ft of 1/2 in. ID hose at 0.75 gpm?

218 psi (from chart) x 2 (viscosity factor 2 x 1000 cps) x

3 (

3 x 50 ft hoses) x 0.75 (% of gpm) = 981 psi loss

Avoid under sizing the high volume side. Pressure drop

during flow

conditions will increase momentary hose

induced ratio errors. See Table 2.

Loading...

Loading...