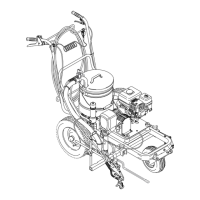

311021 23

Displacement Pump

See manual 309277 for pump repair instructions.

Removal

1. Flush pump.

2. Relieve pressure; page 7.

3. Fig. 11. Remove suction tube (34) and hose (26).

Fig. 11

ti6514a

26

34

C

UTION

Gallon counter may error if magnet ring and/or

sensor assembly are damaged during disassembly

and assembly.

4. Fig. 12. Push magnet ring (222) up. Push retaining

spring (194) up. Push out pin (249).

194

Fig. 12

ti6515a

222

249

5. Fig. 13. Loosen jam nut. Unscrew pump.

Fig. 13

ti6516a

Installation

C

UTION

If the pump jam nut loosens during operation, the

threads of the hydraulic motor manifold will be dam-

aged. Tighten jam nut as specified.

1. Fig. 14. Screw jam nut to bottom of pump threads.

Screw pump completely into manifold. Unscrew

pump from manifold until pump outlet aligns with

hose. Hand tighten jam nut, then tap 1/8 to 1/4

turn with hammer or torque to 200 ft-lb (270 N·m).

Fig. 14

ti6517a

2. Fig. 15. Slowly pull engine starter rope until pump

rod pin hole is aligned with hydraulic rod hole.

Fig. 12. Push pin (249) into hole. Push magnet ring

(222) down. Push retaining spring (194) into

groove.

Fig. 15

ti6518a

222

Fig. 16. Fill packing nut with Graco TSL.

Fig. 16

ti6519a

Loading...

Loading...