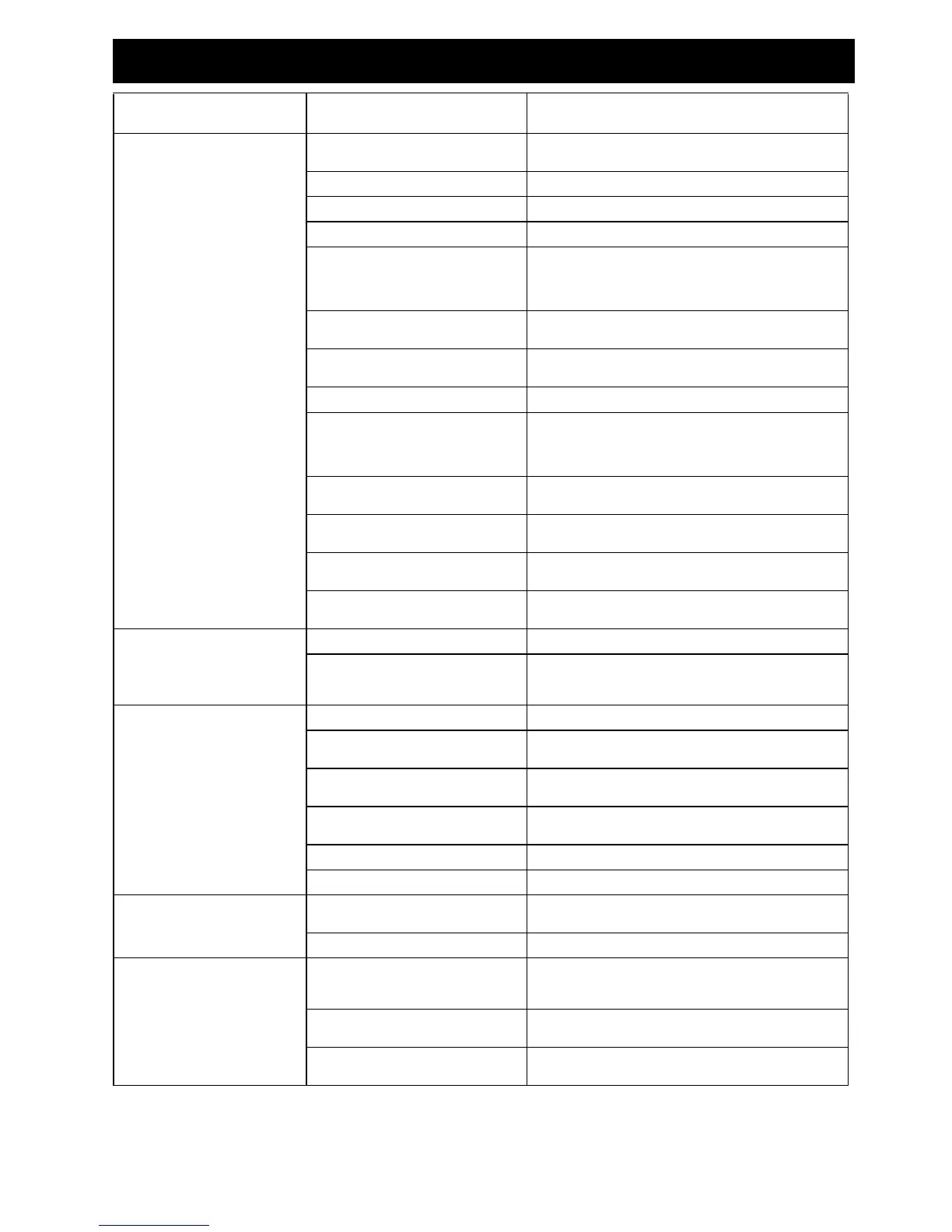

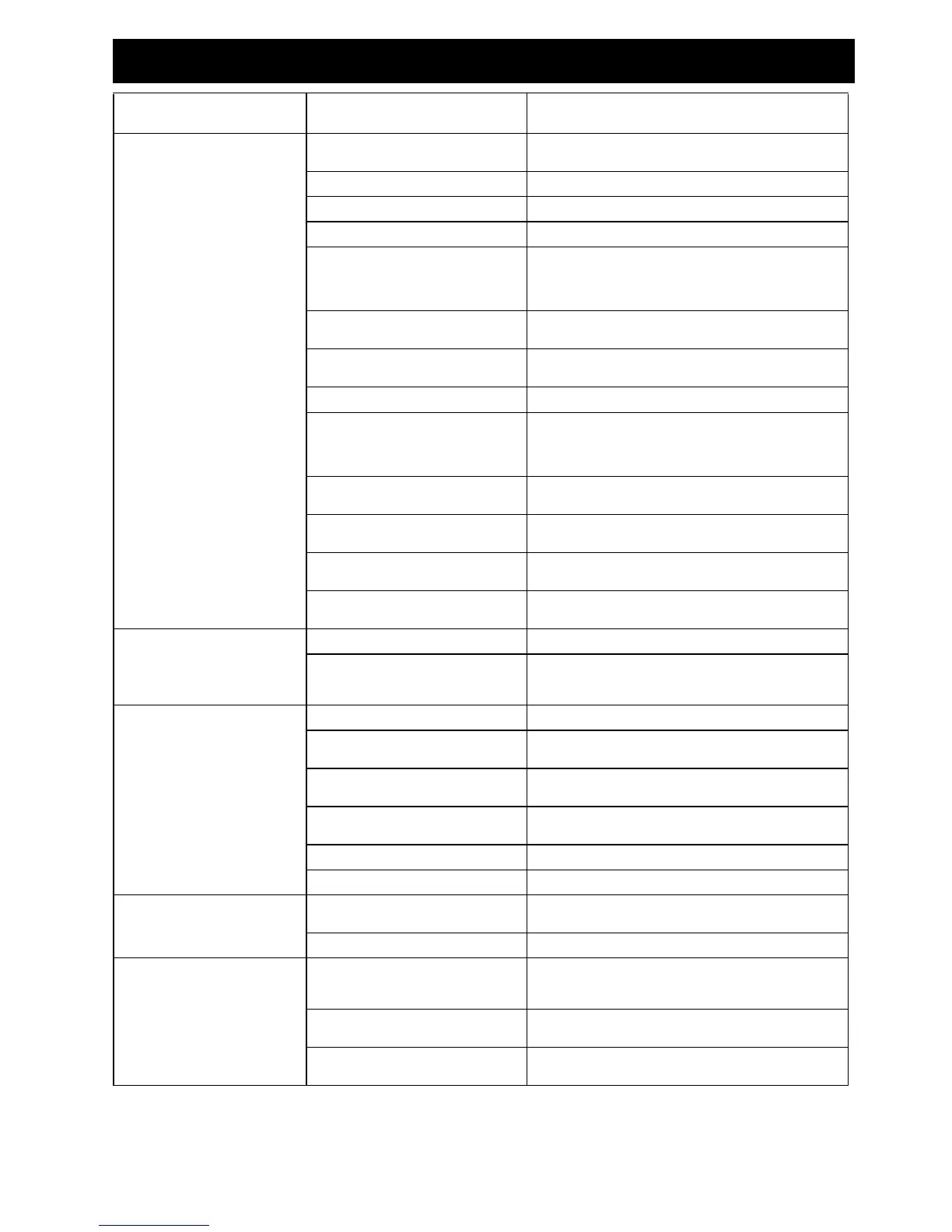

Troubleshooting

3A6342A 37

Pump output is low

Spray tip worn Follow Pressure Relief Procedure, page 19, then

replace tip. See your separate Spray Gun or tip manual.

Spray tip clogged Refer to Clear Spray Tip Clog, page 26

Paint supply is empty Refill and reprime pump.

Suction Tube strainer clogged Remove and clean, then reinstall.

Intake valve ball and piston ball are

not seating properly

Remove intake valve and clean. Inspect balls and seats

for nicks; replace if necessary; see pump manual.

Strain paint before using to remove particles that could

clog pump.

Sprayer filter or Spray Gun filter is

clogged or dirty.

Clean or replace filter.

Prime valve leaking Follow Pressure Relief Procedure, page 19. Replace

prime valve.

Pump is worn. Service pump; see pump manual.

Pump throat packings are worn. Tighten packing nut/wet cup. If leakage continues,

replace packings; see pump manual. Also check piston

valve seat for hardened paint or nicks and replace if

necessary. Tighten packing nut/wet-cup.

Intake valve ball is packed with

material

Clean intake valve; see pump manual.

Pressure setting is too low Turn Pressure Control Knob clockwise to increase

pressure.

Material is too thick for a small

diameter Hose, or Hose is too long.

Use larger diameter Hose and/or reduce overall length

of Hose.

Amp switch is on low setting. (10A or

15A setting)

Switch to 16A or 20A setting.

Fluid is spitting from Spray Gun

Tip is partially clogged Refer to Clear Spray Tip Clog, page 26.

Material supply low, or air was not

properly purged during priming.

Refill fluid supply. Refer to Fill Pump (Prime Pump),

page 21. Then Fill Spray Gun and Hose, page 22.

Check fluid supply often to prevent running pump dry.

Pump is difficult to prime

Intake valve is stuck to seat. Remove foot valve. Clean and inspect intake valve.

Suction tube o-ring on foot valve is

damaged or missing.

Replace Suction Tube o-ring.

Air in pump Refer to Fill Pump (Prime Pump), page 21. Then Fill

Spray Gun and Hose, page 22.

Intake valve is leaking Clean intake valve. Be sure ball seat is not nicked or

worn and that ball seats well. Reassemble valve.

Pump packings are worn Replace pump packings; see pump manual.

Motor does not run

Pressure Control Knob is set too low Increase pressure by turning Pressure Control Knob

clockwise.

Spray tip clogged Refer to Clear Spray Tip Clog, page 26.

Motor runs but pump does not

stroke

Displacement pump pin damaged or

missing; see pump manual.

Replace pump pin if missing. Be sure retainer spring is

fully in groove all around connecting rod; see pump

manual.

Connecting rod assembly damaged;

see pump manual.

Replace connecting rod assembly; see pump manual.

Gears or drive housing damaged. Inspect drive housing assembly and gears for damage

and replace if necessary; see pump manual.

Problem Cause Solution

Loading...

Loading...