Troubleshooting

PROBLEM PROBLEM

PROBLEM

CAUSE CAUSE

CAUSE

SOLUTION SOLUTION

SOLUTION

Loosereversingproximityswitch.

SeePumpsDoNotReverse

Direction,page40.

Loosepistonpackingbolt.

SeePumpsDoNotReverse

Direction,page40.

Pumpsdonotreversedirectionor

pumpsdonotmove.

Faultydirectionalvalve.

SeePumpsDoNotReverse

Direction,page40.

Feedpumppressureistoolow.

Adjustpressuretomaintain100psi

(0.7MPa,7bar)minimum.

Pumpcavitation.

Fluidistoothick.Consultyour

materialsupplierforrecommended

uidtemperaturetomaintaina

viscosityof250to1500centipoise.

Loosereversingproximityswitch.

SeePumpsDoNotReverse

Direction,page40.

Erraticpumpmovement.

Faultydirectionalvalve.Replacedirectionalvalve.

Obstructeduidhoseorgun;uid

hoseIDtoosmall.

Openuidhosetoclearobstruction,

orusehosewithlargerID.

Wornpistonvalveorintakevalvein

displacementpump.

Seepumpmanual.

Pumpoutputlow.

Inadequatefeedpumppressure.Checkfeedpumppressureand

adjustto100psi(0.7MPa,7bar)

minimum.

Fluidleakatpumprodseal.Wornthroatseals.

Replace.Seepumpmanual.

Fluidleakingfrompumpoutlet

rupturedisk.

CheckifheaterandPRESSURE

RELIEF/SPRAYvalve(SAorSB)

areplugged.Clear.Replace

rupturediskwithanewone;donot

replacewithapipeplug.

Nopressureononeside.

Inadequatefeedpumppressure.Checkfeedpumppressureand

adjustto100psi(0.7MPa,7bar)

minimum.

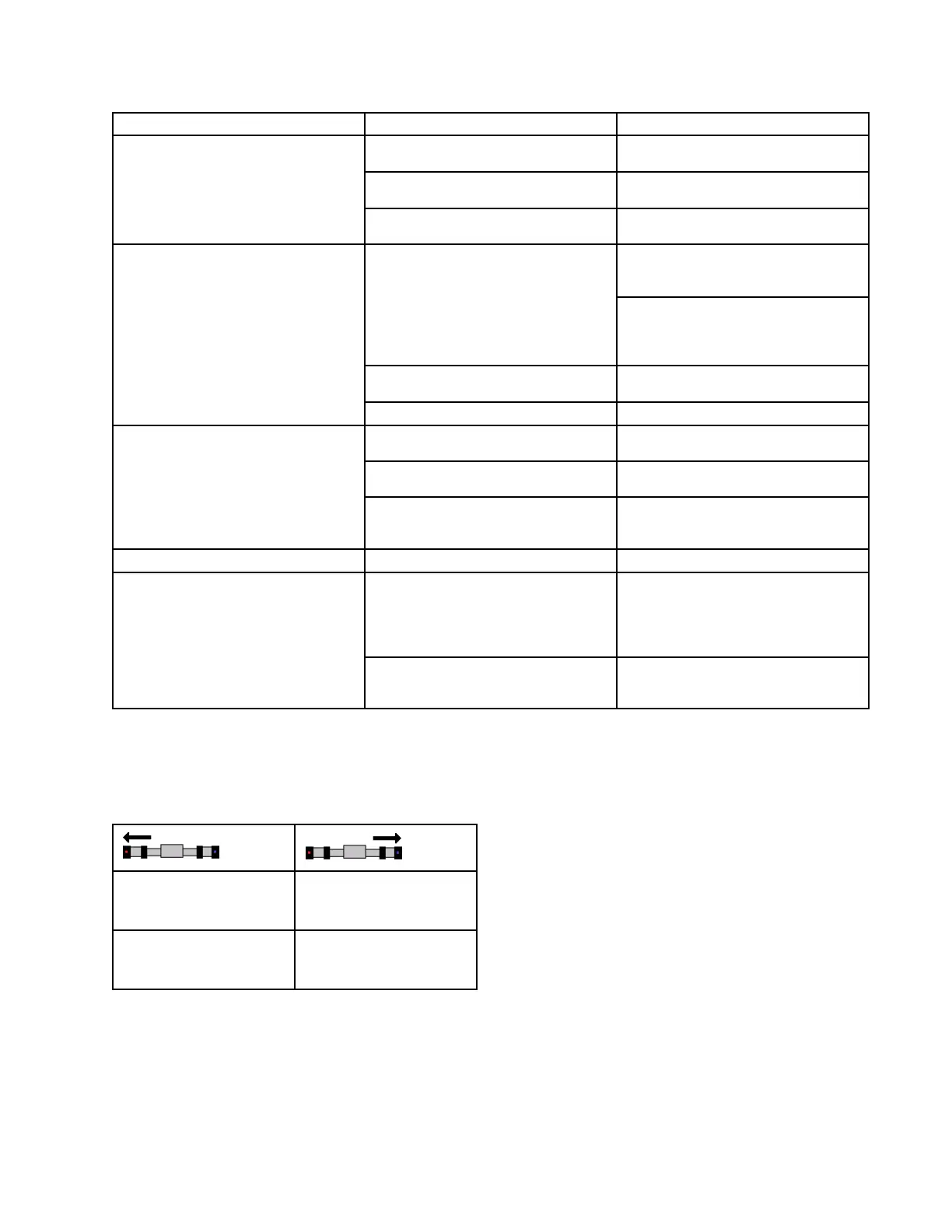

NOTE: NOTE:

NOTE:

Table1isrelatedtotroubleshootingproblem,

“Proportioningpumpdoesnotholdpressurewhen

stalled.”

Table Table

Table

1 1

1

Determine Determine

Determine

Valve Valve

Valve

Leak Leak

Leak

Location Location

Location

B-sidepumppiston

valveisdirtyor

damaged.

B-sidepumpinletvalve

isdirtyordamaged.

A-sidepumpinletvalve

isdirtyordamaged.

A-sidepumppiston

valveisdirtyor

damaged.

Pressure/Material Pressure/Material

Pressure/Material

Imbalance Imbalance

Imbalance

Todeterminewhichcomponentisoutofbalance,

checkthecolorofsomesprayedmaterial.

Two-componentmaterialsareusuallyamixof

lightanddarkuids,sotheunder-proportioned

componentcanoftenbereadilydetermined.

Whenyouhavedeterminedwhichcomponentis

under-proportioned,sprayoff-target,focusingonthe

pressuregaugeforthatcomponent.

For example:

ifcomponentBisunder-proportioned,

focusontheB-sidepressuregauge.IftheB

gaugereadsconsiderablyhigherthantheAgauge,

theproblemisatthegun.IftheBgaugereads

considerablylowerthantheAgauge,theproblem

isatthepump.

334946H 39

Loading...

Loading...