Maintenance

Flush Flush

Flush

Inlet Inlet

Inlet

Strainer Strainer

Strainer

Screen Screen

Screen

Theinletstrainerslteroutparticlesthatcan

plugthepumpinletcheckvalves.Inspectthe

screensdailyaspartofthestartuproutine,and

cleanasrequired.

Isocyanatecancrystallizefrommoisture

contaminationorfromfreezing.Ifthechemicals

usedarecleanandproperstorage,transfer,and

operatingproceduresarefollowed,thereshould

beminimalcontaminationoftheA-sidescreen.

CleantheA-sidescreenonlyduringdaily

startup.Thisminimizesmoisturecontamination

byimmediatelyushingoutanyisocyanate

residueatthestartofdispensingoperations.

1.FollowthePressureReliefProcedure,page

30.

2.If If

If

using using

using

electric electric

electric

transfer transfer

transfer

pumps: pumps:

pumps:

Turnoffthe

mainpower(MP).

If If

If

using using

using

pneumatic pneumatic

pneumatic

transfer transfer

transfer

pumps: pumps:

pumps:

Turnoff

thetransferpumps.Seeyourpumpmanual,

RelatedManuals,page3.

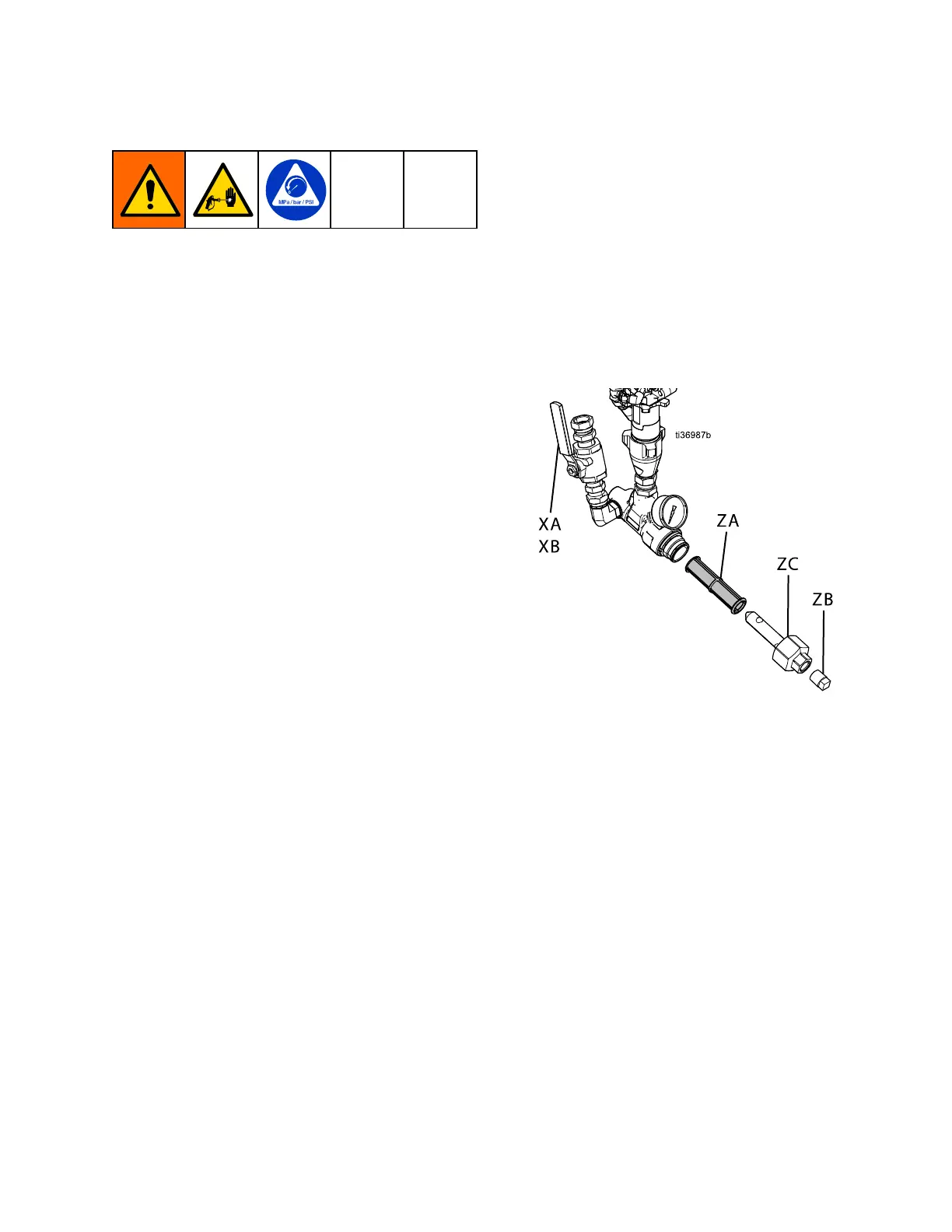

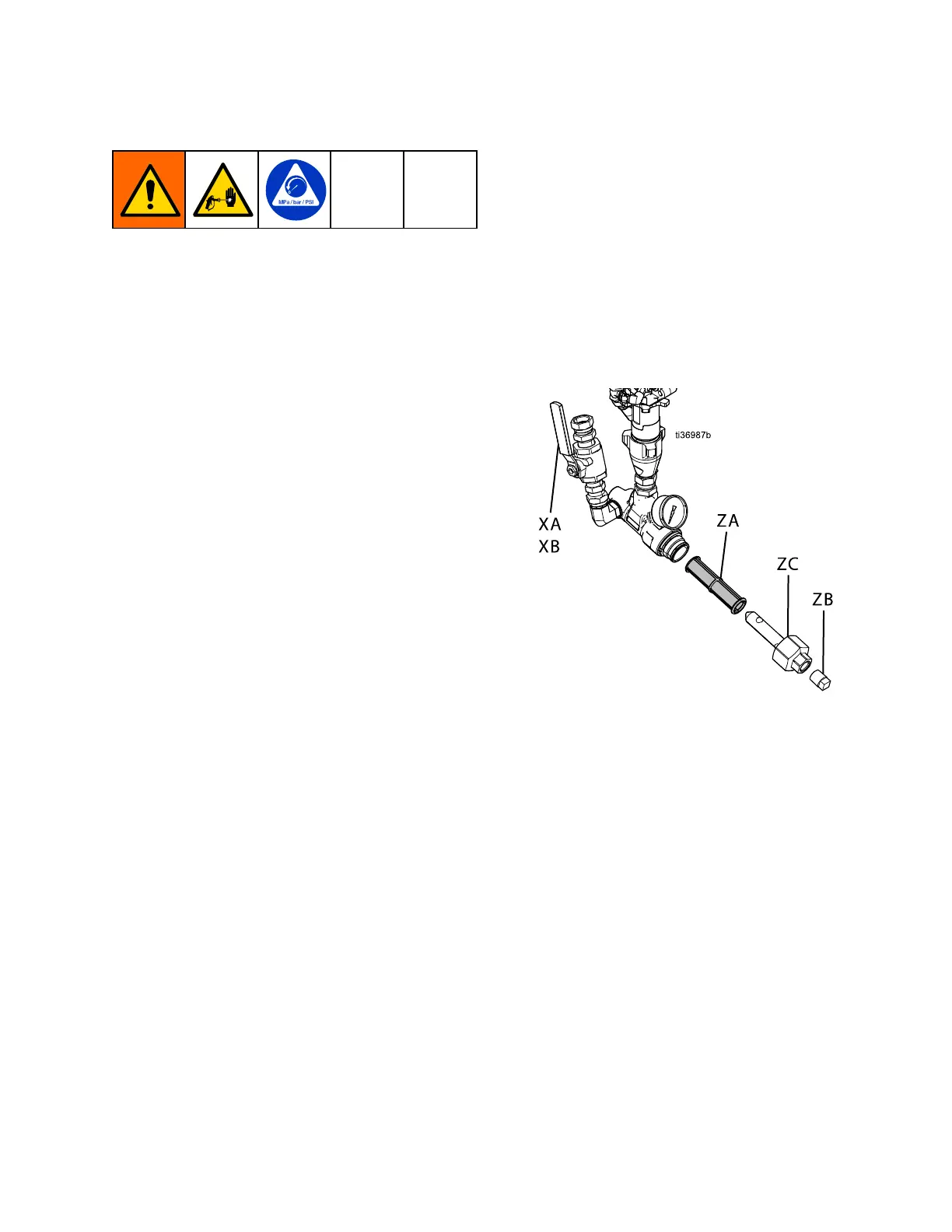

3.ClosetheFluidInletValve(XA)atthepump

inlet.Thispreventsmaterialfrombeing

pumpedwhilecleaningthescreen.

4.Placeacontainerunderthestrainerbaseto

catchdrainoffwhenremovingthestrainer

drainplug(ZB).

5.Aftertheuidhasdrained,removethe

cap(ZC)andscreen(ZA)fromthestrainer

manifold.Thoroughlyushthescreenwith

compatiblesolventandshakeitdry.Inspect

thescreen.Nomorethan25%ofthemesh

shouldberestricted.Ifmorethan25%ofthe

meshisblocked,replacethescreen.Inspect

theo-ring.Greaseandreplacetheo-ring

asrequired.

6.Installthestrainerplug(ZB)withthescreen

(ZA).

7.OpentheFluidInletValve(XA),ensurethat

therearenoleaks,andwipetheequipment

clean.Cleanandgreasethethreads.

Proceedwithoperation.

3A8500A 49

Loading...

Loading...