308–626

7

Installation

Electrical Grounding contrinued from page 6.

3.

Use only electrically conductive

fluid hoses

with a

maximum of 500 feet (150 m) combined hose

length to ensure grounding continuity

.

4.

Obtain electrical grounding continuity for the

spray

gun

by connecting it to a properly grounding fluid

hose and pump or sprayer

.

5.

Provide electrical grounding for these components

according to the local code: the

fluid supply

container

, the

object being sprayed,

and

all of

the solvent pails used when flushing.

Use only

metal pails, which are conductive. Do not place the

pail on a non-conductive surface, such as paper or

cardboard, which interrupts the grounding continu

-

ity.

6. To maintain grounding continuity when flush-

ing or relieving pressure

,

always hold a metal

part of the gun firmly to the side of a

grounded

metal pail, then trigger the gun.

Operation

Pressure Relief Procedure

INJECTION

HAZARD

T

o reduce the risk of serious injury

, in

-

cluding fluid injection, splashing in the

eyes or on skin, or injury from moving

parts, always follow this procedure whenever the

spray equipment is shut of

f, when checking or serv

-

icing any part of spray system, when installing,

cleaning or changing spray tips and whenever you

stop spraying.

WARNING

1.

Lock the gun safety knob.

2.

Shut of

f the power supply to the pump and open

any air bleed valves in the system.

3.

Unlock the gun safety knob.

4.

Hold a metal part of the gun firmly to the side of a

grounded

metal waste container

, and trigger the

gun to relieve pressure.

5.

Lock the gun safety knob.

6.

Open the pump drain valve to help relieve fluid

pressure in the pump, hose and gun. T

riggering

the gun to relieve pressure may not be suf

ficient.

Have a container ready to catch the drainage.

7.

Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged or that pressure has not been fully relieved

after following the steps above, V

ER

Y SLOWL

Y

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually

, then loosen completely

.

Now clear the tip or hose obstruction.

INJECTION HAZARD

The wallet-sized warning card provided

with this gun should be kept with the op

-

erator at all times. The card contains

important treatment information should a fluid injec

-

tion injury occur

. Additional cards are available at

no charge from Graco, Inc.

WARNING

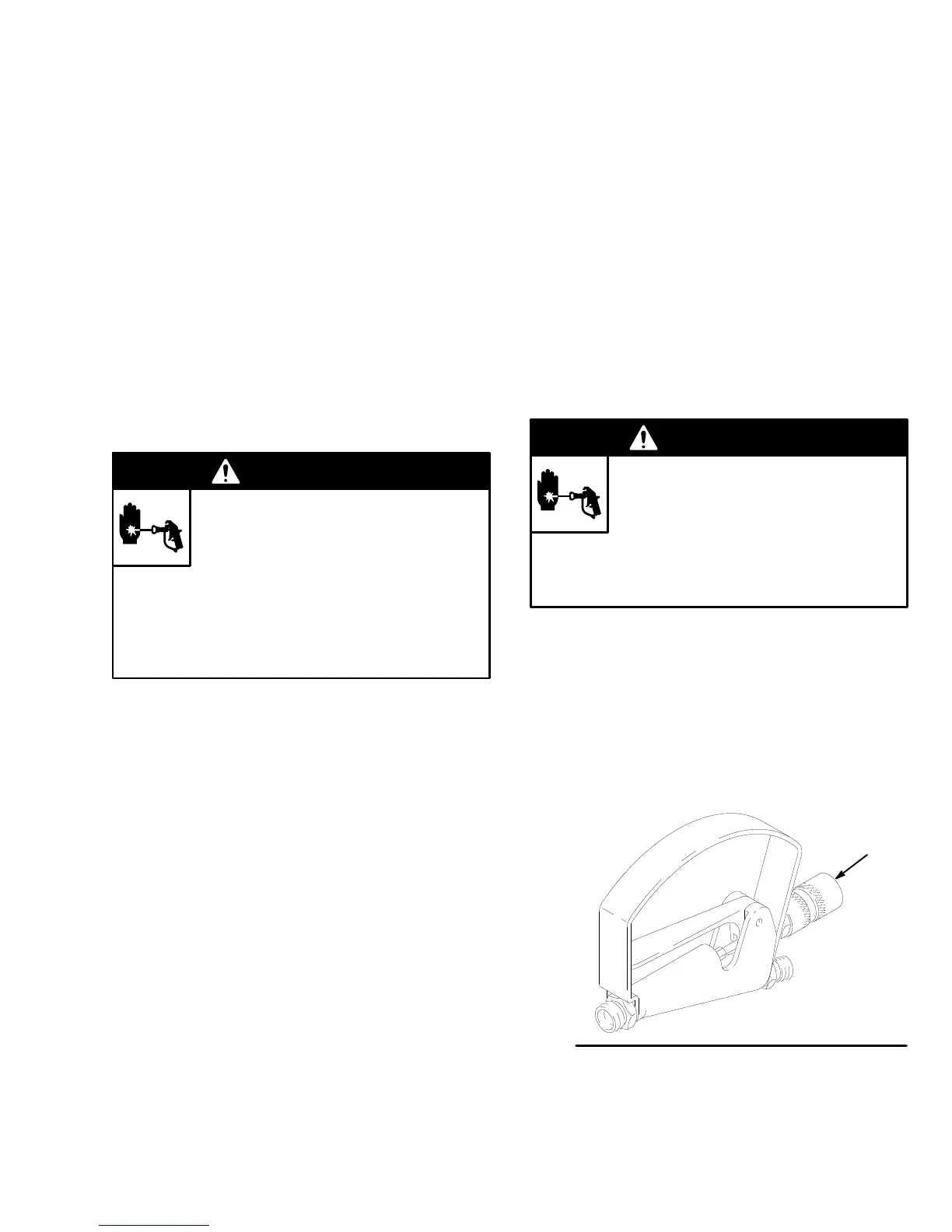

How to Use the Safety Knob

To

lock the safety knob (A), turn the knob fully clock

-

wise; this locks the needle in the forward position. T

o

unlock the safety knob, turn the knob fully counter

-

clockwise. See Fig. 2.

Fig. 2

A

04884

Loading...

Loading...