Section 3: Installation Information Page 11

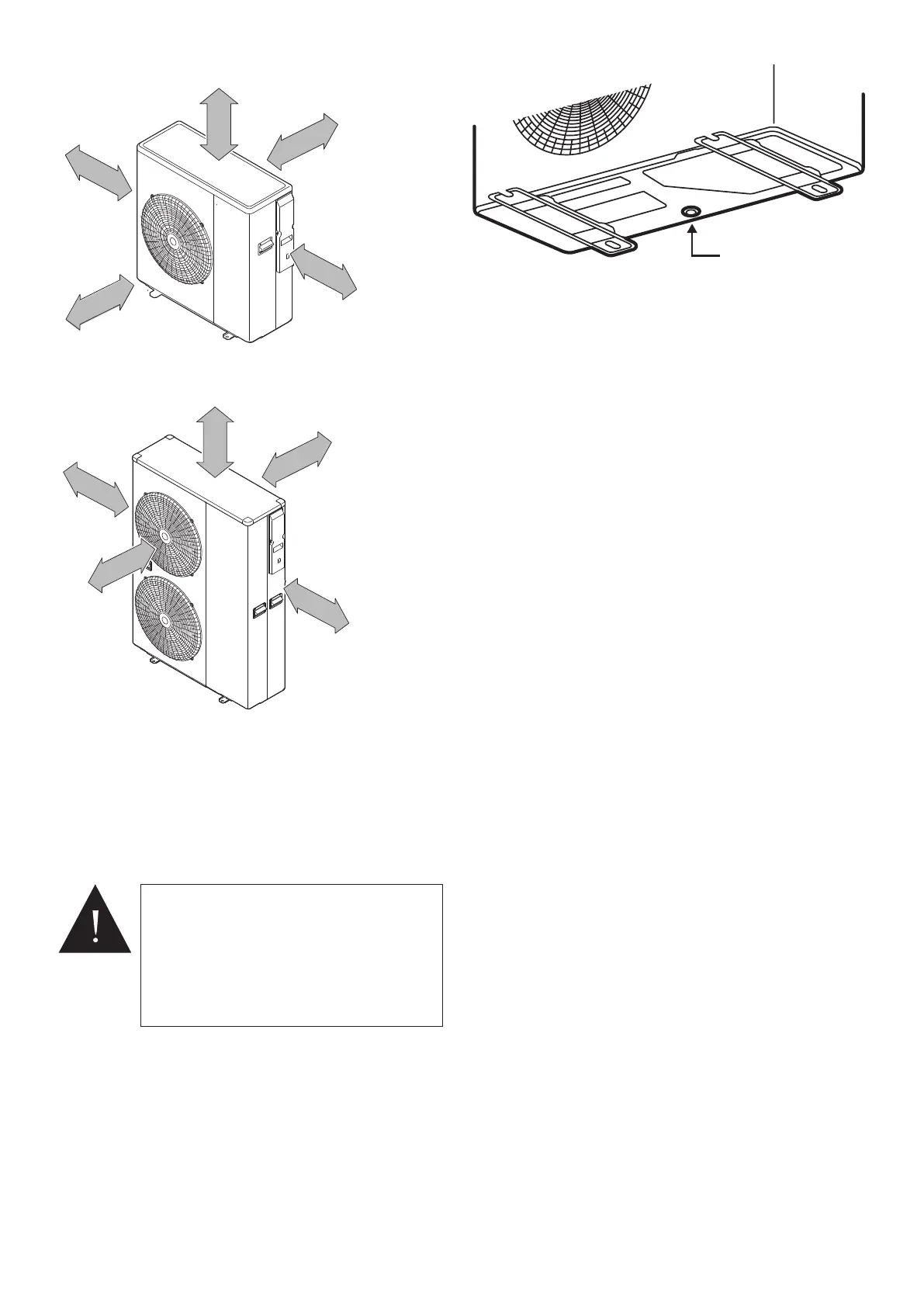

Condensate outlet

Figure 3-4: Condensate outlet

3.5.4 Vibration

If the vibration from the heat pump is likely to cause a nuisance, use the

anti-vibration mounts (product code: HPIDFOOT/KIT) and fix the heat pump

securely to the mounts.

3.6 Installing the Heat Pump

3.6.1 Insulation

The complete water circuit, including all pipework, must be insulated to

prevent heat loss reducing the efficiency of the heat pump and also to prevent

damage due to frozen pipes.

3.6.2 Connecting the Heating System to the Heat Pump

• Water connections must be made in accordance with diagram in this

manual and the labels on the heat pump.

• Be careful not to deform the heat pump pipework by using excessive

force when connecting.

• Pipework should be flushed before connecting the heat pump.

• Hold the pipe end downwards when removing burrs.

• Cover the pipe end when inserting it through a wall so that no dust and

dirt enter.

• The heat pump is only to be used in a sealed heating system.

It must not be used as part of an open-vented system.

Before continuing the installation of the heat pump, check the following points:

• The maximum system water pressure is 3 bar.

• Make sure the hose is connected to the pressure relief valve to avoid any

water coming into contact with electrical parts.

• Air vents must be provided at all high points of the system. The vents

should be located at points which are easily accessible for servicing. An

automatic air purge valve is provided inside the heat pump. Check that

the air purge valve can operate.

• Take care that the components installed in the pipework can withstand

the water pressure.

3.6.3 System Connections

The system connections of the heat pump must be carried out using the flexible

hoses, valves and fittings supplied with the heat pump.

The hydraulic circuit must be completed following the recommendations

below:

1. It is important to install the isolation valves between the heat pump and

the building.

2. The system must have drain cocks in the lowest points.

3. Air vents must be included at the highest points of the system.

4. A system pressure gauge must be installed upstream of the heat pump.

5. All pipework must be adequately insulated and supported.

6. The presence of solid particles in the water can obstruct the heat

exchanger. Therefore, protect the heat exchanger using a magnetic filter

such as a Grant Mag-One, fitted internally.

7. After system assembly flush and clean the whole system, paying

particular attention to the state of the filter.

8. A new installation must be thoroughly flushed and cleaned before filling

and adding anti-freeze/biocide/inhibitor.

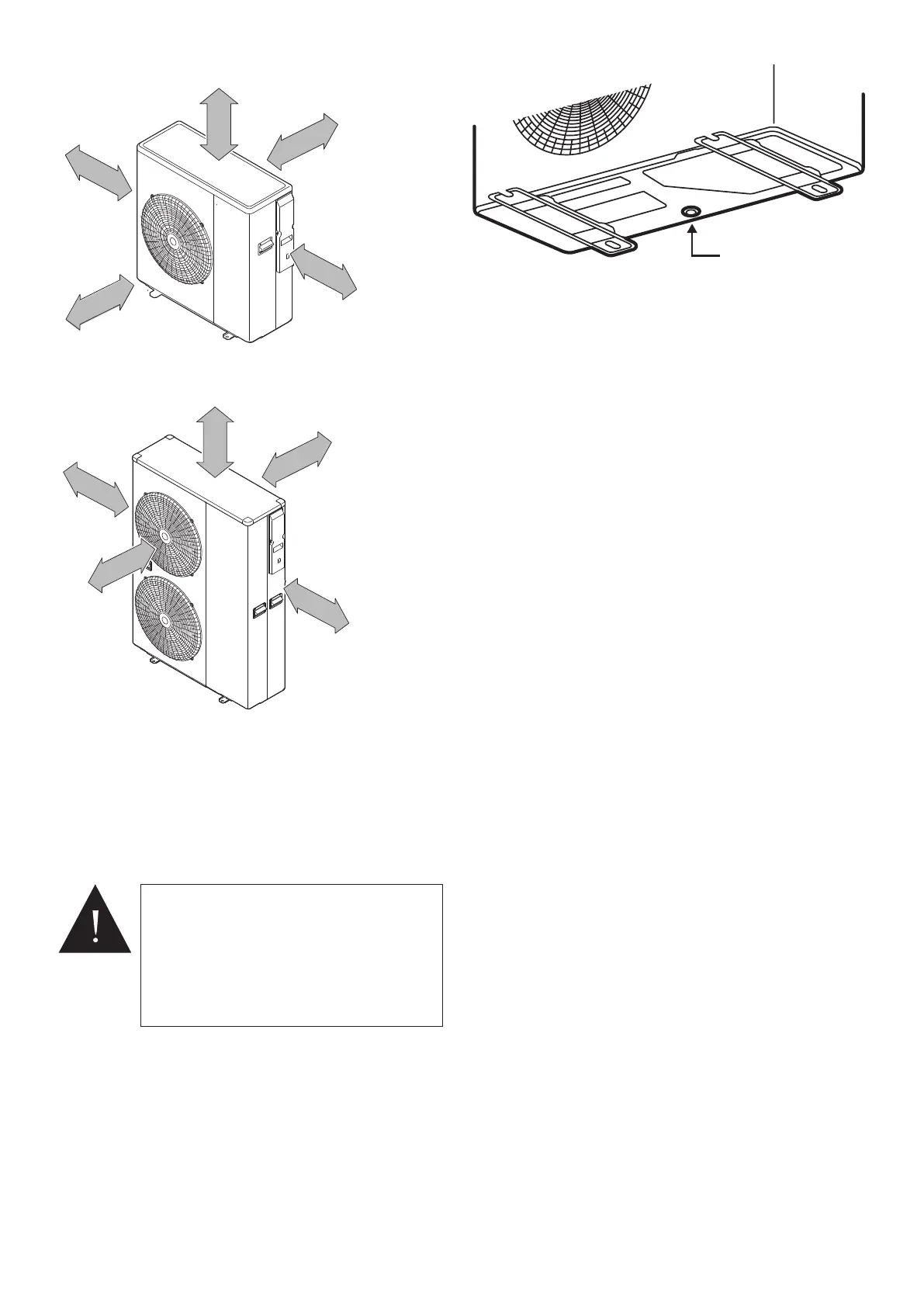

003 revO mm

Over 600 mm

Over 100 mm

Over 300 mm

Over 600 mm

HPID10

003 revO mm

Over 600 mm

Over 100 mm

Over 300 mm

Over 600 mm

Figure 3-3: Clearances

3.5.3 Condense Disposal

The underside of the heat pump has a condensate outlet (refer to Figure 3-3)

that allows any condensate to drain from the heat pump.

Provision must be made to safely collect and dispose of the condensate.

For example, use 40 mm waste pipe to form a condensate disposal system

into which the condensate flows from the opening in the bottom of the heat

pump casing running to a suitable gulley or soakaway.

WARNING

It is essential that the condensate is able to

drain away and not allowed to run onto any

adjacent paths or driveways where, in winter,

this will result in icing and a potential hazard

for anyone walking near the heat pump.

The top of the concrete base must be either

level with, or above, the surrounding ground

level.

HPID10R32

HPID13R32 & HPID17R32

Figure 3-2: Clearances

Loading...

Loading...