Section 3: Installation Information Page 15

3.12 Installation Checklist

Location and positioning

• The vibration damping feet/shoes are fitted (if supplied)

• The heat pump is fixed to the surface or mountings that it rests on

• Maintenance clearances comply with those given in this manual

• The position of the remote controller complies with the guidance given in

this manual

• All safety requirements have been complied with

Water circuit pipework and appliances

• Water connections have been carried out as per the information in this

manual

• All water connections are tight with no leaks

• The magnetic in-line filter is installed on the primary circuit return as close

to the heat pump as possible but still within the building and in a position

that is easy to access for maintenance

• The pressure gauge with a suitable scale is installed on the sealed system

pipework or expansion vessel manifold

• The connection pipes are suitably supported so that these do not weigh

on the appliance

• The expansion vessel installed on the heating circuit is suitably sized

• The low-loss header or volumiser tank is installed if the water content is

insufficient (13 & 17kW units only - refer to Section 3.8)

• The water circuit has been thoroughly flushed

• The air vent valves are installed at the highest points on the system

• There is no air in the system (vent if necessary)

• The shut off valves are installed on the inlet/outlet of system circuit

• The drain valves are installed at the lowest points in the system

• The flexible hoses are installed on the inlet/outlet of system circuit

• The system water content complies with the specification in the manual

• The DHW immersion heater has been installed in DHW tank for

Legionella prevention

• Suitable water flow rate for operation of the entire heat pump is

achieved as specified in this manual. Refer to Section 9.12

• All pipes are insulated with suitable vapour barrier material to prevent

formation of condensation and heat loss, with control and shut-off

devices protruding from the insulation

Electrical connections

• All electrical connections are secure

• Electrical connections have been carried out correctly

• Voltage is within a tolerance of 10% of the rated voltage for the heat

pump (230V)

• Electrical power supply complies with the data on the rating plate and

as specified in the manual

• The earth wires are connected securely

2. Set the parameter group number to 43 using the Up or Down q button.

3. Press the + buttons o and the second two digits (the parameter code)

will blink.

4. Set the parameter code number to 00 using the Up or Down q button.

5. Press Set button p and the parameter value 4300 (1 = enabled) will be

displayed and will blink.

6. Reset the parameter value 4300 to 0 (disabled) using the Up or Down

q button.

Repeat this process to reset the values of parameters 4310, 4320 and 4330

to 0.

Return to normal operation:

Press and hold the Menu l and the – or + o buttons together for 3 seconds or

simply leave the remote controller for 10 minutes.

3.11 Completion

Please ensure that the heat pump commissioning form (supplied with the heat

pump) is completed in full and that it is signed by the householder/user.

Leave the copy with the user and retain one copy for your own records.

Ensure that these installation and servicing instructions and the user

instructions are handed over to the householder.

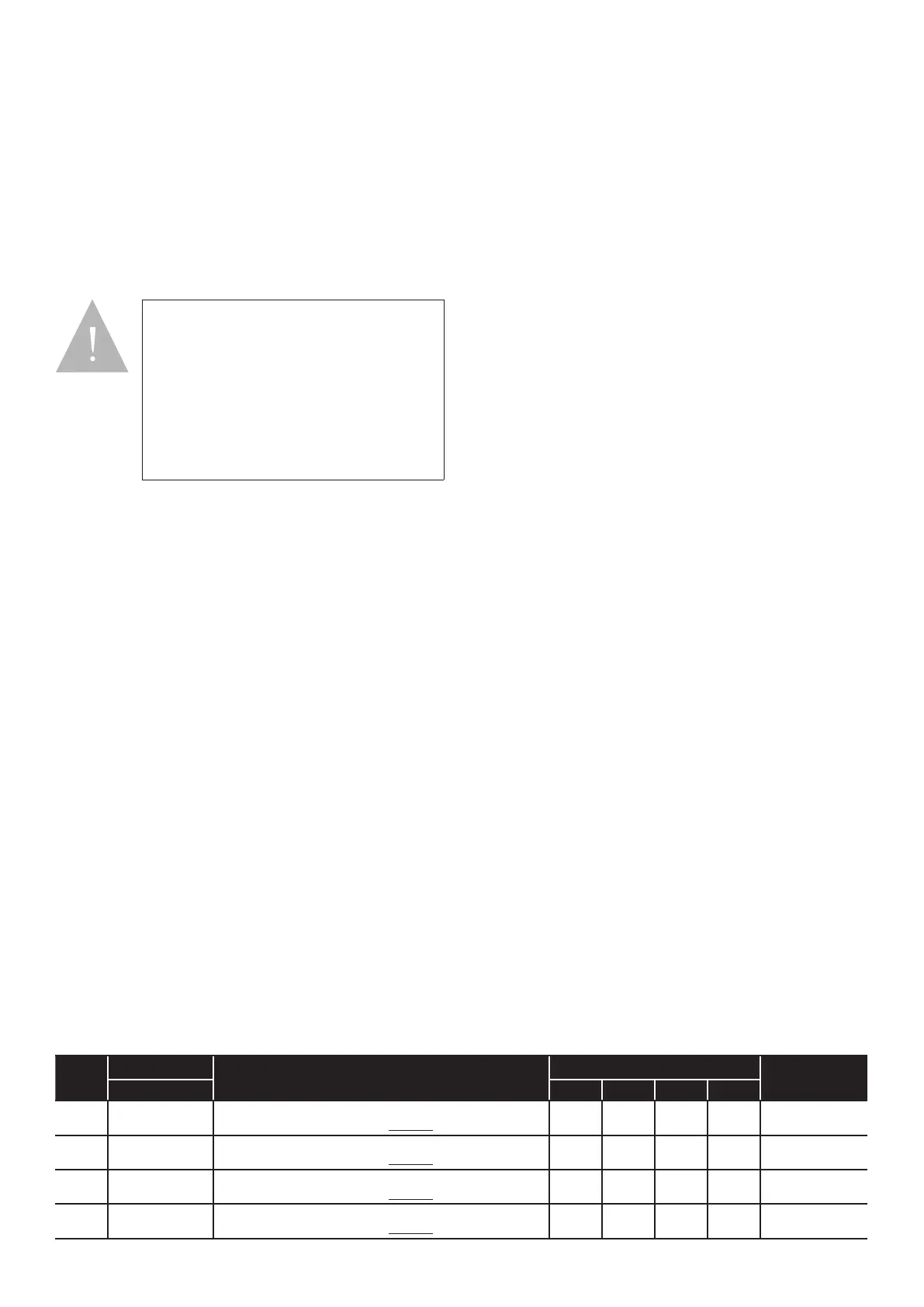

Table 3-9: Frost protection parameters

Level

Parameter

Function description

Display and input value

Remarks

Group Code Default Min. Max. Unit

S 43 00

Frost protection on room temperature

0=disable 1=enable

1 0 1 -

S 43 10

Frost protection by outside temperature

0=disable 1=enable

1 0 1 -

S 43 20

Frost protection based on outgoing water temperature

0=disable 1=enable

1 0 1 -

S 43 30

DHW storage frost protection

0=disable 1=enable

1 0 1 -

Do NOT disable the heat pump antifreeze

function unless a suitable concentration of

glycol is present in the system water. Refer to

Table 3-7. If there are any leaks of water from

the heating system and the system requires

topping up then the concentration of ethylene

glycol must be checked and topped up as

required.

Failure to follow this instruction will invalidate

the product guarantee.

NOTE

Loading...

Loading...