Section 4: Sealed System Page 19

Pressure Gauge

The pressure gauge must have an operating range of 0 to 4 bar.

It must be located in an accessible place next to the filling loop for the system.

Safety Valve

The safety valve (provided with the heat pump) is set to operate at 3 bar. It

should be fitted in the flow pipework near to the heat pump. The safety valve

should be connected to a discharge pipe which will allow the discharge to

be seen, but cannot cause injury to persons or damage to property.

Filling Loop

Provision should be made to replace water lost from the system. This can

be done manually (where allowed by the local water undertaking) using

an approved filling loop arrangement incorporating a double check valve

assembly.

The filling loop must be isolated and disconnected after filling the system.

Heating System

The maximum ‘setpoint’ temperature for the central heating water is 55°C.

An automatic air vent should be fitted to the highest point of the system.

If thermostatic radiator valves are fitted to all radiators, a system by-pass must

be fitted. The by-pass must be an automatic type and correctly set when the

system is commissioned.

All fittings used in the system must be able to withstand pressures up to 3 bar.

Radiator valves must comply with the requirements of BS 2767:1991.

One or more drain taps (to BS 2879) must be used to allow the system to be

completely drained.

4.2 Filling the Sealed System

Filling of the system must be carried out in a manner approved by the local

Water Undertaking.

The procedure for filling the sealed system is as follows:

1. Check the air charge pressure in the expansion vessel BEFORE filling

the system.

The expansion vessel charge pressure should always be approximately

0.2 bar lower than the maximum static head of the system, at the level

of the vessel (1 bar = 10.2 metres of water).

Refer to Figure 4-1.

The charge pressure must not be less than the actual static

head at the point of connection.

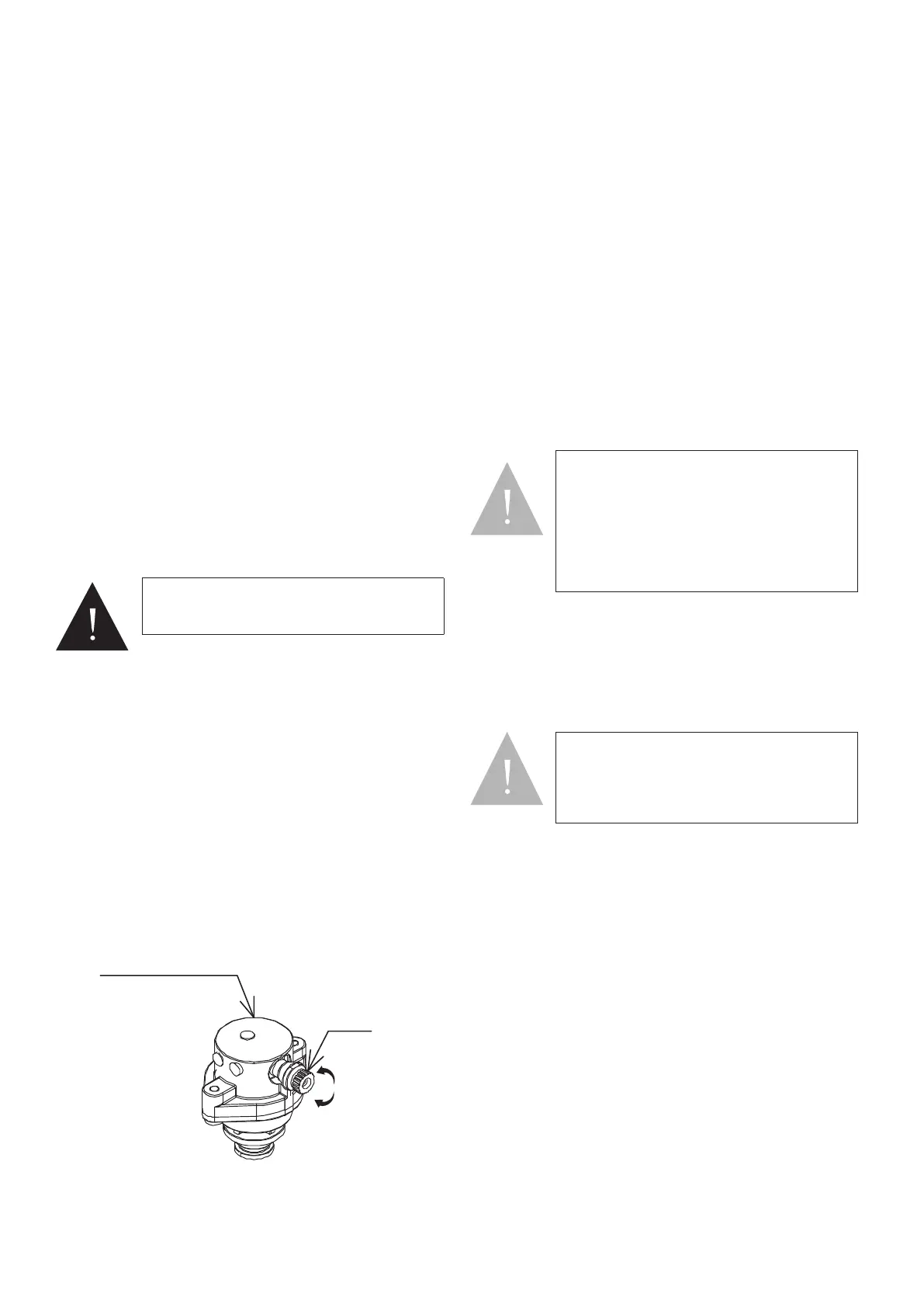

2. Check that the small cap (or screw) on all automatic air vents is open at

least one turn. The cap (or screw) remains in this position until filling is

completed and then it is closed.

3. Remove the top (6kW) and front right (10kW and 13 & 17kW) casing

and loosen the plug on the automatic air vent located inside the heat

pump. Refer to Figure 4-3.

loosen

tighten

Auto air vent

Plug

Figure 4-3: Auto Air Vent

4. Ensure that the flexible filling loop is connected and that the double

check shut off valve connecting it to the water supply is closed. A valve

is open when the operating lever is in line with the valve, and closed

when it is at right angles to it.

5. Open the fill point valve.

6. Gradually open the double check valve from the water supply until

water is heard to flow.

7. When the needle of the pressure gauge is between 0.5 and 1.0 bar,

close the valve.

8. Vent each radiator in turn, starting with the lowest one in the system, to

remove air.

9. Continue to fill the system until the pressure gauge indicates between

0.5 and 1.0 bar. Close the fill point valve. The system fill pressure

(cold) should be 0.2 - 0.3 bar greater than the vessel charge pressure

– giving typical system fill pressures of approx 0.5 bar for a bungalow

and 1.0 bar for a two storey house.

Refer to the Domestic Heating Design Guide for further information if

required.

10. Repeat steps 8 and 9 as required until system is full of water at the

correct pressure and vented.

11 . Water may be released from the system by manually operating the

safety valve until the system design pressure is obtained.

12. Close the fill point and double check valves either side of the filling loop

and disconnect the loop.

13. Check the system for water soundness, rectifying where

necessary.

14.

4.3 Pressure Relief (Safety) Valve Operation

Check the operation of the pressure relief (safety) valve as follows:

1. Turning the head of the valve anticlockwise until it clicks. The click is the

safety valve head lifting off its seat allowing water to escape from the

system.

2. Check that the water is escaping from the system.

3. Top-up the system pressure, as necessary.

WARNING

Only ever fill or add water to the system when

it is cold and the heat pump is off. Do not

overfill.

The air charge pressure may be checked using

a tyre pressure gauge on the expansion

vessel Schraeder valve. The vessel may

be re-pressurised, when necessary, using

a suitable pump. When checking the air

pressure, the water in the heating system must

be cold and the system pressure reduced to

zero.

The expansion vessel air pressure, system

pressure and operation of the pressure relief

valve must be checked on each service. Refer

to Section 10.

NOTE

NOTE

Loading...

Loading...