Section 6: Electrical

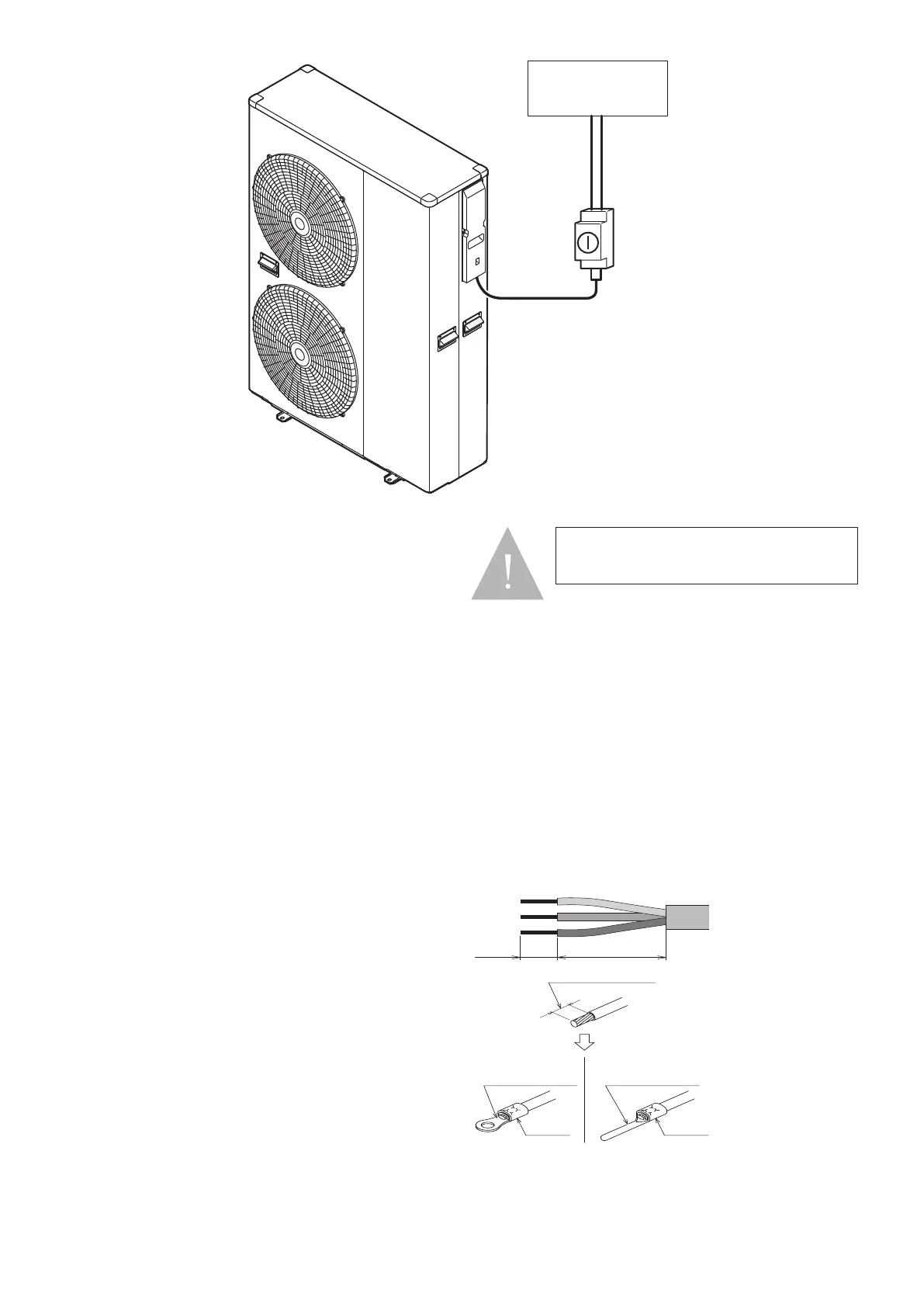

Strip ends of connecting cables in accordance with Figure 6-6.

Crimp terminals with insulating sleeves can be used if required as illustrated

in the diagram below for connecting the wires to the terminal block. Stranded

conductors shall not be soldered.

• Use a circuit breaker with a 3 mm clearance of air gap between the

contacts.

• Be sure to FULLY insert the cable cores into the proper position of the

terminal block.

• Faulty wiring may cause not only abnormal operation but also damage

to PCB board.

• Fasten each terminal screw securely.

• To check the connections are secure, pull the cable slightly.

10 mm 30 mm

Terminal block

Crimp terminal

Stripped wire :10mm

Sleeve

Crimp terminal

Sleeve

PCB(Terminal)

Figure 6-5: Stripping the cables

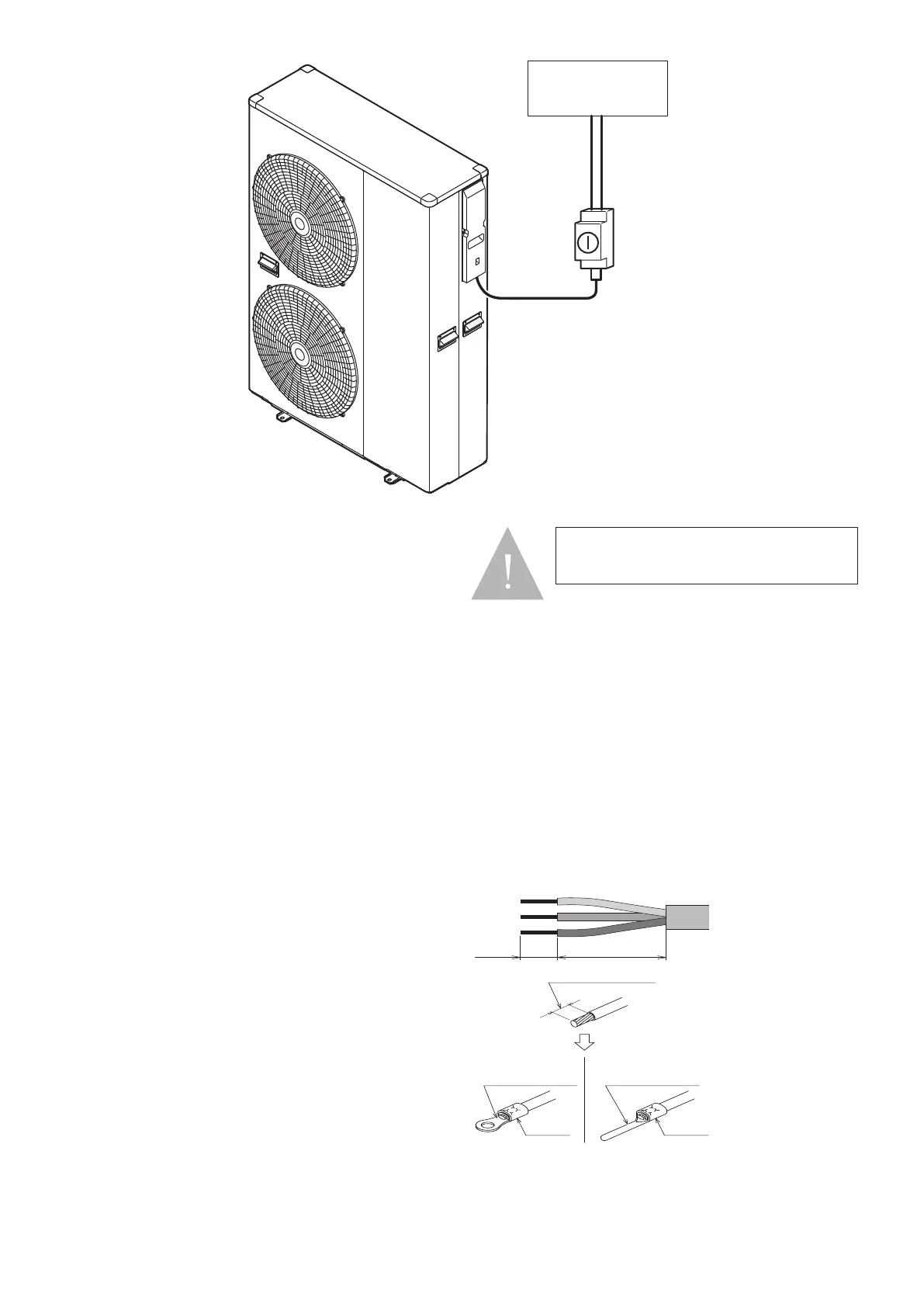

Lockable

isolator

Consumer

unit

Figure 6-4: Heat pump, isolator and consumer unit

6.4 Wiring first fix options

Mains supply

All heat pump models to have a twin and earth from main fuse board wired to

outdoor unit through an external isolator

6kW – 3 x 2.5mm2 – 16A RCBO

10kW – 3 x 4mm2 – 20A RCBO

13/17kW – 3 x 6mm2 – 32A RCBO

Grant wiring centre – located in cylinder area

5 x 0.75mmsq from Grant wiring center to the heat pump externally, sheilded

if over 30m.

Heat pump controller

2 x 1mm2 shielded cable from the Grant wiring centerto the controller and

should be shielded.

Immersion

3 x 2.5mm2 from main fuse board to immersion wired through Grant supplied

time boost kit

Cylinder Stat

Live & Neutral – linked from L&N on Grant wiring centre – 2 x 1.5mm2

Load & Common – 2 x 1mm2 from wiring centre to cylinder stat.

Note: If using pre plumbed cylinder, the cylinder wiring is already done.

If underfloor heating is present

Boiler/heating call cable from underfloor heating wiring centre/s to Grant

wiring centre – 2 x 1mm2

UFH circulating pump/valve wired back to Grant wiring centre – 2 x 1mm2

Page 26

In the case of long cable runs, selection of

correct cable must be done in accordance with

BS 7671 (IET Wiring Regulations)

NOTE

Loading...

Loading...