1/02

23

D

IRECTION

C

ONTROL

P

EDAL

IMPORTANT:

Correct adjustment of the direction control

pedal is necessary to prevent severe damage to the

hydrostatic transmission.

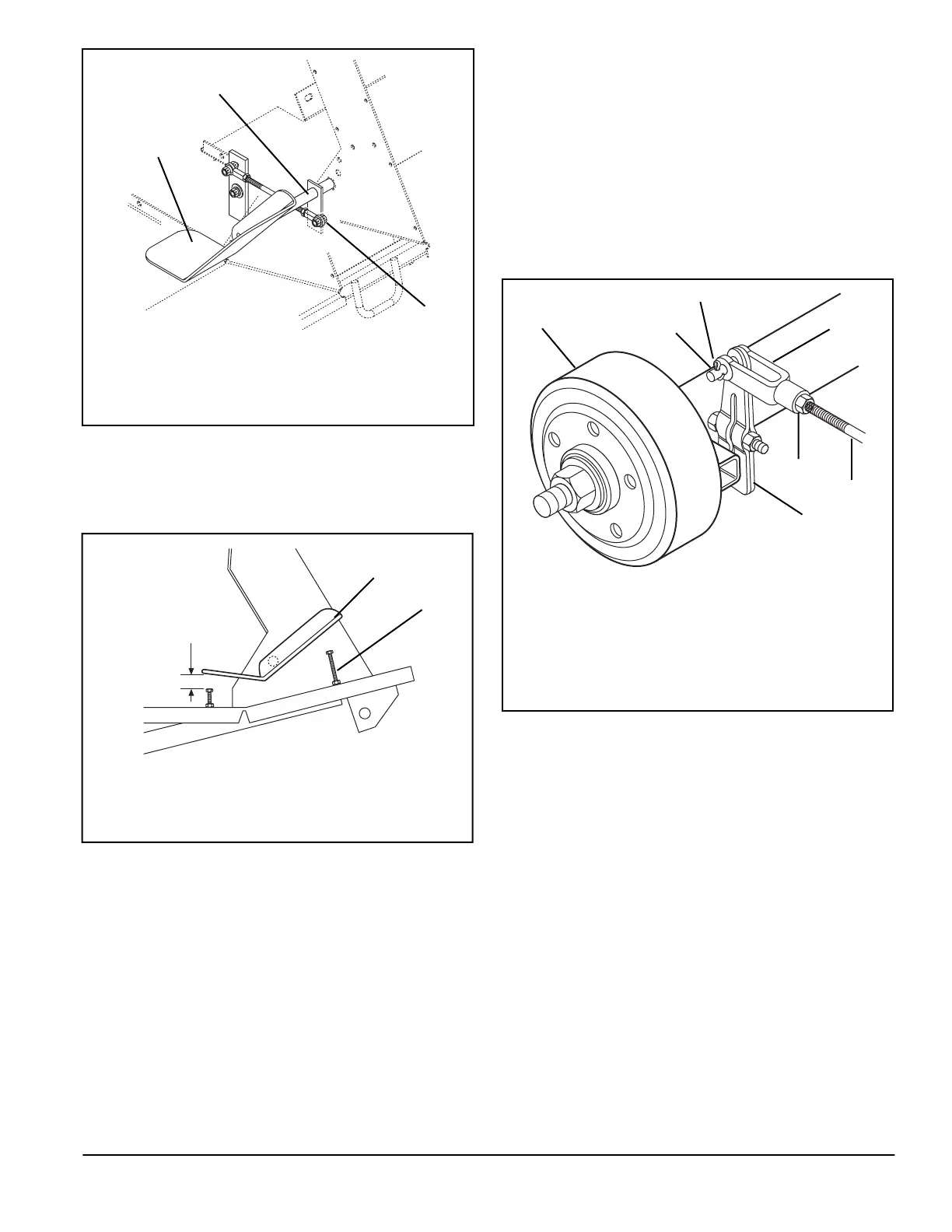

To adjust pedal (Figure 12):

1. Remove bolt connecting rod end to direction control

weldment.

2. Adjust rod end until pedal is at an angle which is

comfortable for the operator. Turn rod end

counterclockwise to move pedal angle toward

operator and clockwise to move pedal angle away

from operator.

3. Replace hardware holding rod end to direction

control weldment.

4. Adjust Control Pedal Stop Bolts

To adjust Pedal Stop Bolts (Figure 13):

1. Adjust Control Pedal to comfortable position as

above.

2. Set Forward Stop Bolt so pedal hits bolt at full

forward stroke.

B

RAKES

After each use of unit, wash dirt from brakes with water.

Each day before operation, inspect all parts and

fasteners. Repair or replace any missing, worn or

damaged brake or linkage parts. Tighten all nuts and

bolts.

Brake service is required if brakes do not stop and hold

unit effectively. Brakes should activated with 1/2”-3/4” of

foot pedal travel.

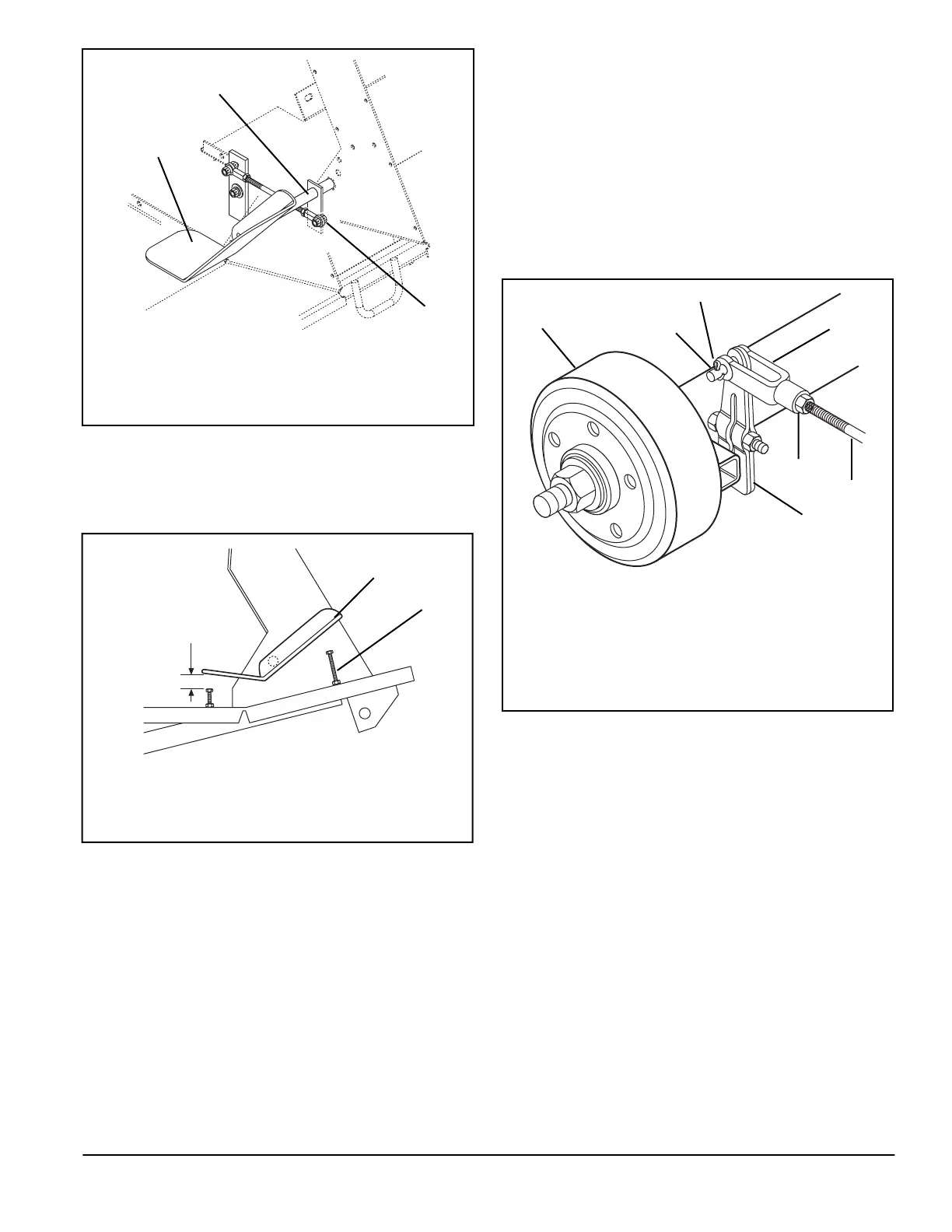

As necessary to compensate for brake lining wear, adjust

brake linkage as follows (Figure 14):

1. Stop unit on a level surface.

2. Stop engine and block wheels so unit cannot roll.

3. Remove cotter pin and clevis pin holding brake

control rod clevis to cam lever arm on the right

individual wheel brake. Loosen jam nut.

4. Turn clevis on brake control rod until correct

adjustment is achieved.

5. Fasten brake control rod clevis to cam lever arm with

clevis pin and cotter pin. Tighten jam nut.

6. Carefully test operation of right individual wheel

brake. If necessary, repeat above procedures to get

correct braking action.

7. Adjust left individual wheel brake as above so that

pedal travel is equal for both brakes.

IMPORTANT:

Replace brake shoes before lining is worn

to rivet heads.

If correct braking action cannot be achieved after

performing these procedures, do the following:

1

3

2

1. Direction Control Pedal

2. Rod End

3. Direction Control Weldment

Figure 12

OF1511

1. Pedal (Neutral Position)

2. Forward Stop Bolt

Figure 13

1

2

OF1480

1

4

3

2

5

6

7

Figure 14

OF0461

1. Brake

2. Clevis Pin

3. Cotter Pin

4. Brake Control Rod

Clevis

5. Jam Nut

6. Brake Control Rod

7. Cam Lever Arm

Loading...

Loading...