82

DC Inverter Multi

VRF Service Manual

5.11.3 Vacuum pumping

The steps are as follows:

a. Expel the nitrogen after leakage detection;

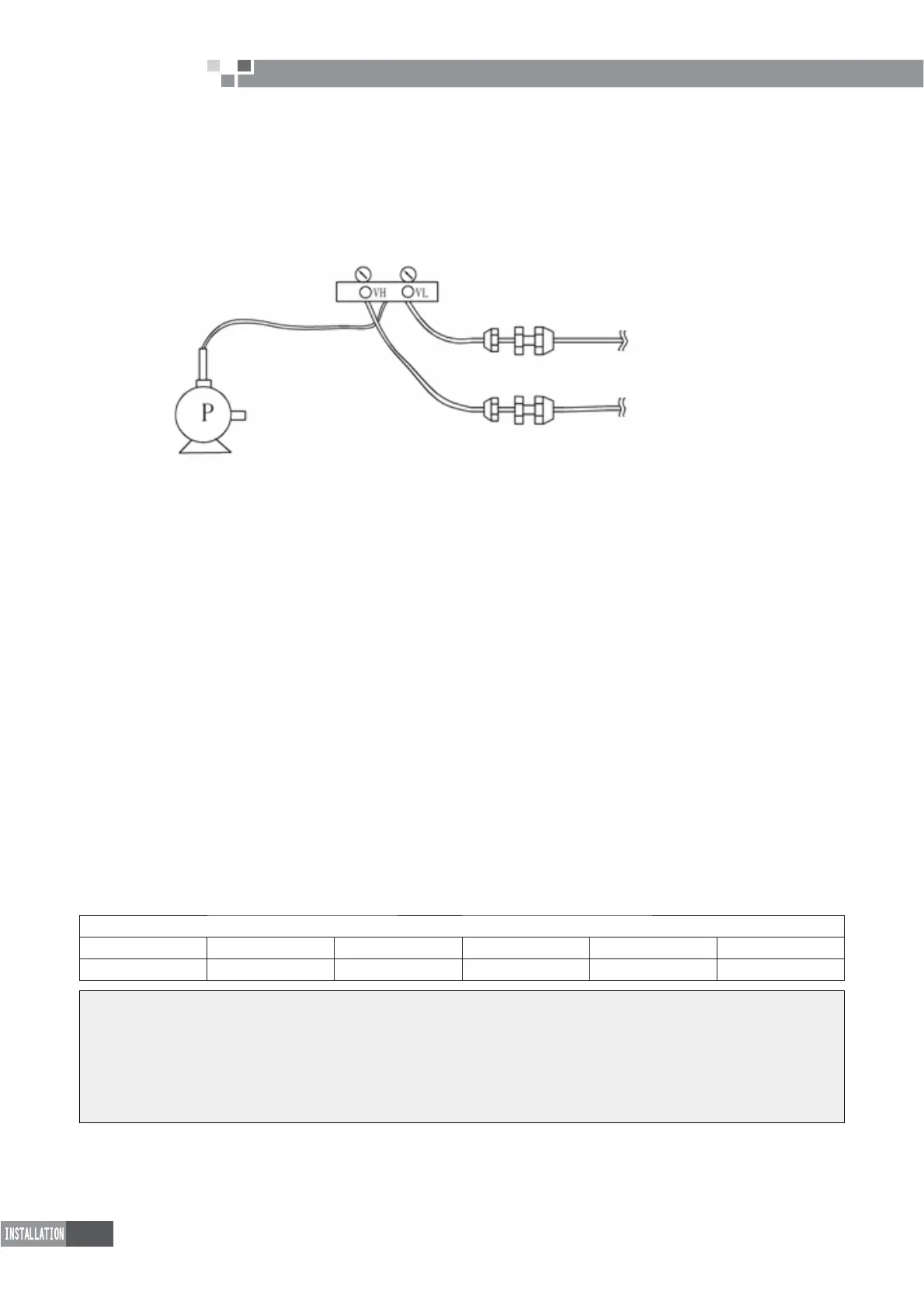

Connect the pressure gauge to Freon nozzle on outdoor liquid valve and gas valve, and connect a vacuum

pump. Then, establish vacuum simultaneously from high pressure side and low pressure side.

Connector on liquid side

Pressure gauge connector valve

Connector on gas side

Vacuum pump

Start the vacuum pump and turn on “LO” and “HI” knobs;

b. Continue for 0.5~1.0 hour after the vacuum level reaches -0.1MPa (gauge pressure -1kgf/cm2). Then,

close the “VH” knob on high pressure end and “VL” knob on low pressure end to stop the vacuum pump.

c. Remove the hose connected to vacuum pump and reconnect it to the refrigerant tank. Expel the air

in the hose. Open the “VL” knob on low pressure end to charge refrigerant to the system piping. When the

pressure reaches 0.0kgf/ cm2, close the “VL” knob on low pressure end.

d. Remove the hose connected to refrigerant tank and reconnect it to vacuum pump. Start the vacuum

pump and open the “VH” knob on high pressure end. Pump for 30 minutes from high pressure end and then

open the “VL” knob to pump from low pressure end, until the vacuum level reaches -0.1MPa (gauge pressure

-1kgf/cm2).

If the vacuum level reaches -0.1MPa (gauge pressure) or lower, the vacuuming process is then ended.

Stop the vacuum pump and place still for 1 hour. Then, check the vacuum level for any change. In case of any

change, it indicates that there is leakage. In this case, proceed to leakage detection and repair.

H:KHQWKHSURFHGXUHVIRUYDFXXPSXPSLQJDUH¿QLVKHGUHIULJHUDQWVKDOOEHFKDUJHG

5.12 Refrigerant Charge

5.12.1 Calculation method for refrigerant charging

5HIULJHUDQWVKDOOEHFKDUJHGDFFRUGLQJWRFDOFXODWHGDPRXQWVSHFL¿HGLQHQJLQHHULQJGUDZLQJV

Method for calculation of added refrigerant volume (based on liquid pipe)

0DVVRIUHIULJHUDQWWREHFKDUJHG OHQJWKRIOLTXLGSLSHîUHIULJHUDQWFKDUJHDPRXQWRIHYHU\PHWHURI

liquid pipe.

Amount of refrigerant charge for every meter of liquid pipe(kg/m)

ĭ ĭ ĭ ĭ ĭ ĭ

0.35 0.25 0.17 0.11 0.054 0.022

Note:

a. Standard pipe length is 15m. If refrigerant piping (L) is shorter than or equal to 15m, no additional

refrigerant is needed If piping is longer than 15m (based on liquid pipe), more refrigerant shall be

added. The above table shows how much refrigerant shall be charged for every one additional meter

of piping.

b. Electronic balance shall be used for refrigerant charge.

c. Thickness of pipe wall shall be 0.5~1.0mm and pressure-bearing capability shall be 3.0MPa.

d. The longer the piping, the more refrigerating capacity and heating capacity shall be weakened.

Loading...

Loading...