Section - Charging with HC refrigerant R-290

Steps recommended

No

Where Activities

1

Carry out all intended works without hurry and

THINK BEFORE ACTING!

2

Continuing from section - Evacuation

3

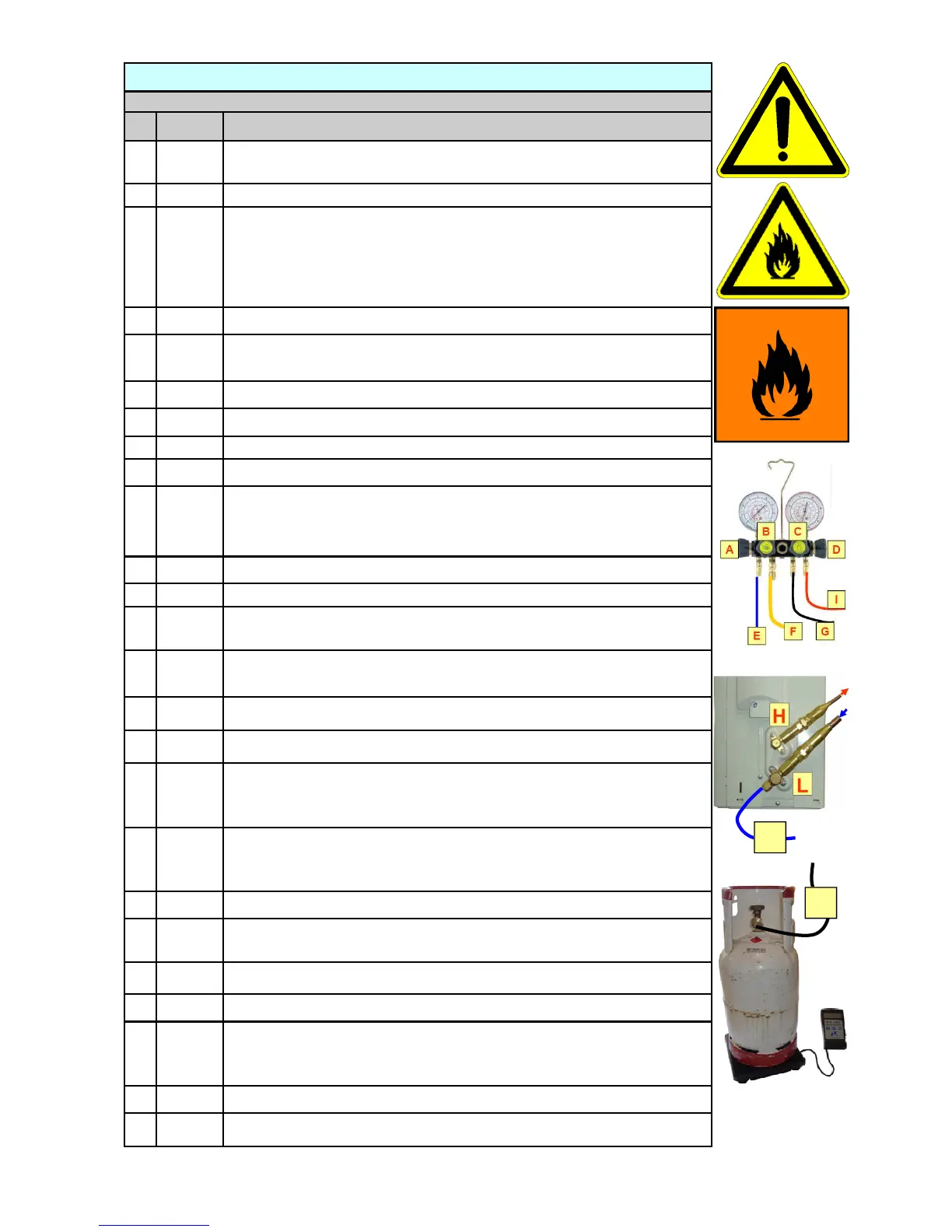

Arrange your tools and equipment connections as indicated on page 96.

Ensure that the refrigerant transfer hose “E” with the connection at the suc-

tion line service port “L” consists of a core depressor to open the service port

inner core valve during connection. The warning sign is placed in the work-

area.

4

AC system “OFF”, evacuated and dehydrated.

5

A, B,

C, D

Manifold gauge valves are closed.

6

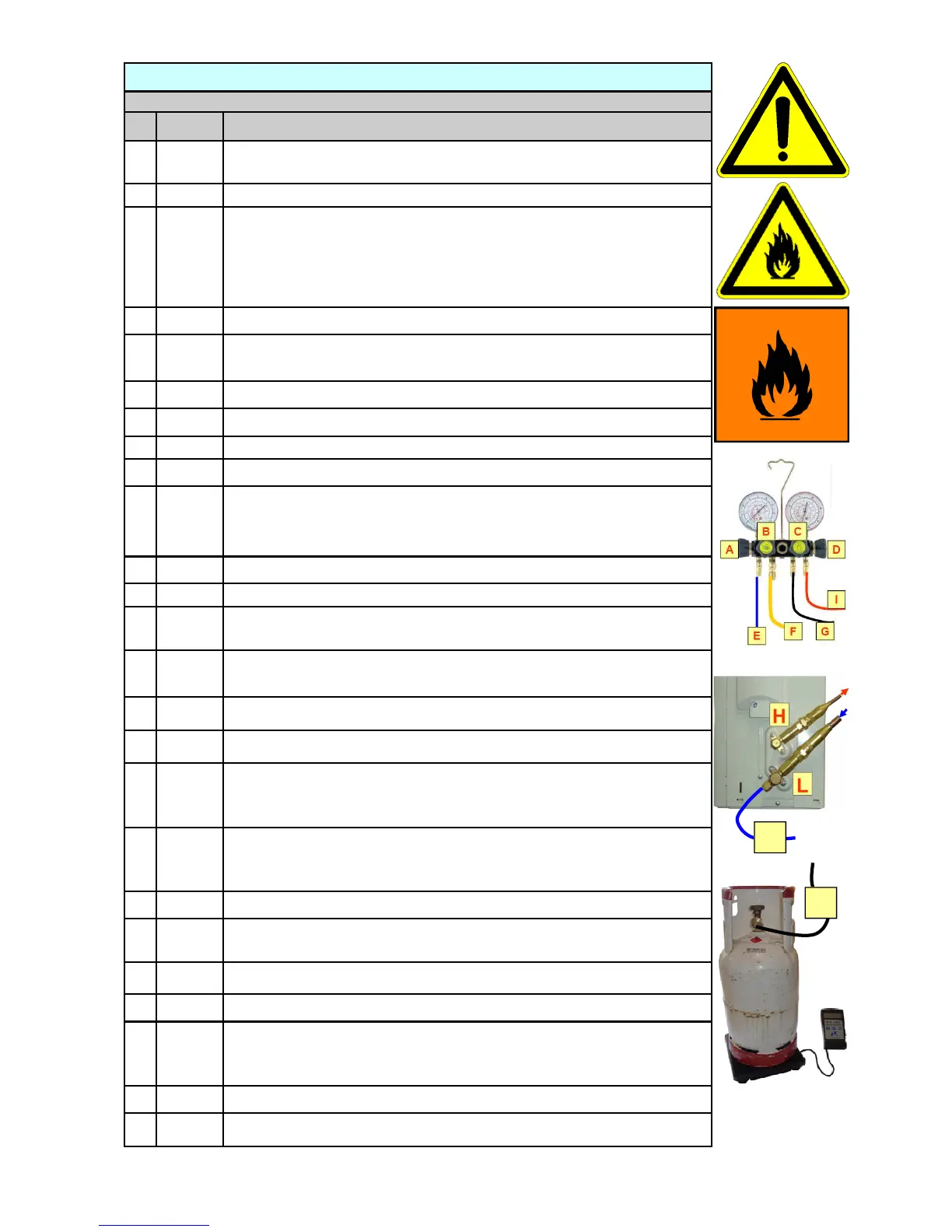

L & H

Stop valves at condensing unit are open

7

Open the refrigerant cylinder valve

8

Zero the weighing scales

9

A

Open the low pressure valve at the manifold gauge.

10

C

Open the refrigerant valve at the manifold gauge. Transfer refriger-

ant vapour slowly (50% of total charge) into the suction side of the

condensing unit

11

Measure (note) transferred (charged) refrigerant amount

12

C

Close the refrigerant charging valve of the manifold gauge set.

13

Switch on the unit to COOLING MODE, bearing in mind that there

is a time delay of 3 minutes until the compressor starts.

14

C

Open the refrigerant charging valve “C” of the manifold gauge set

and slowly charge accurately the remaining refrigerant amount.

15

Close the refrigerant cylinder valve

16

Record the system data (use provided form from page 102).

17

H

Close stop valve at condensing unit (HP). Stem in front-seated po-

sition to pump down and transfer the refrigerant into the high side

section of the AC unit.

18

If low pressure gauge indicates 0 bar, all refrigerant remaining in

the hoses assembly and gauges manifold set is sucked back into

the AC unit.

19

A

Closed

20

H

Open the high pressure stop valve at the outdoor unit. Stem in

back-seated position.

21

B, C, D

Closed

22

Remove Manifold and install end-caps.

23

L & H

Final leak check with soapy water or electronic HC leak detector.

H – while operational AC unit

L – in “off“ mode

24

General functional test of the system and system labelling.

25

Fill Start-Up data sheet for “Service and Repair” works

G

E

Loading...

Loading...