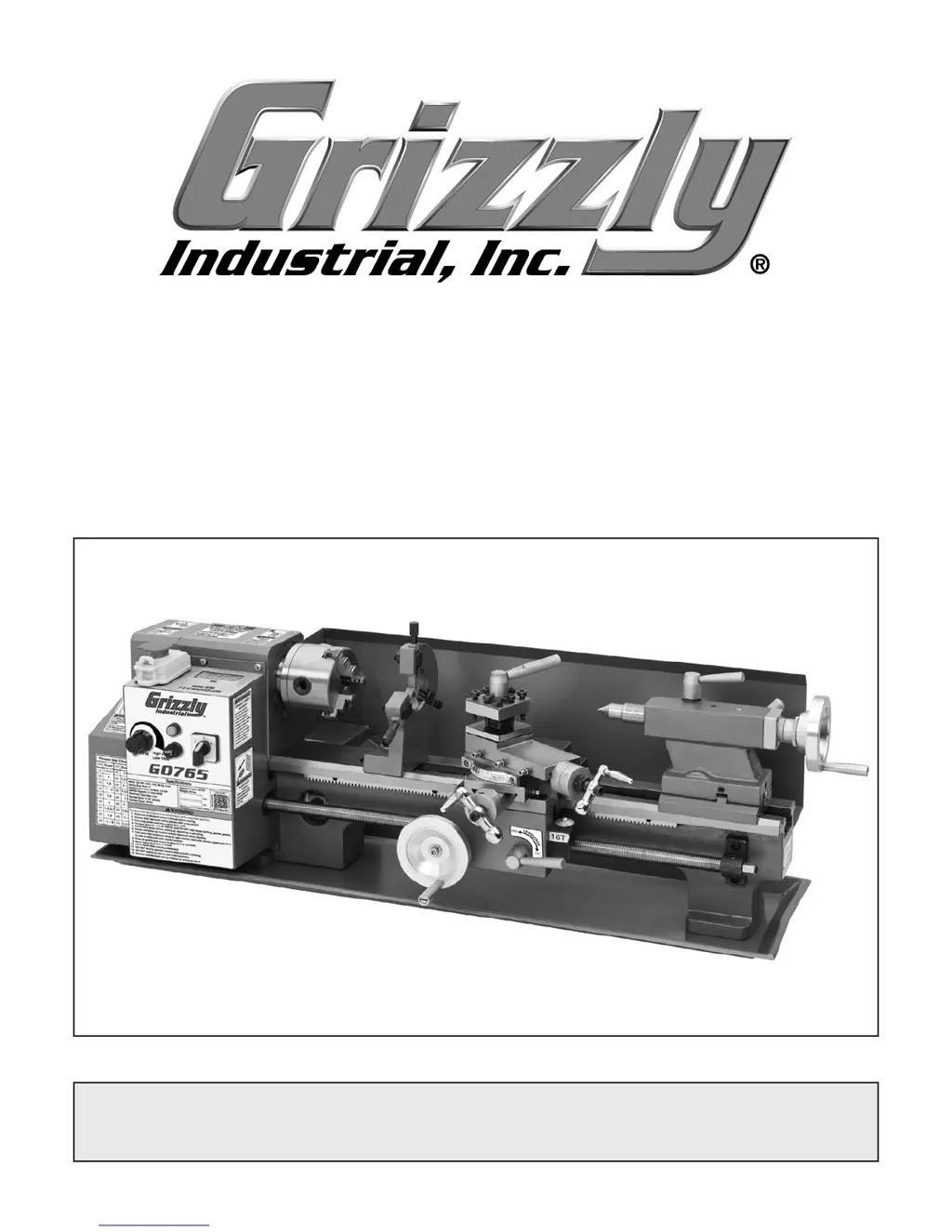

What to do if my Grizzly Lathe stalls or is underpowered?

- SStacey DiazAug 12, 2025

If your Grizzly Lathe is stalling or underpowered, start by decreasing the feed rate and cutting speed. Ensure you are using the correct type and size of metal for the workpiece. If the machine is undersized for the task, inspect and replace if at fault. Overheating can also cause stalling, so use sharp bits, and reduce the feed rate and depth of cut. Other potential causes include a faulty motor speed dial (test and replace if at fault), a slipping timing belt (tension or replace the belt, ensuring pulleys are aligned), or a pulley/sprocket slipping on the shaft (replace the loose pulley/shaft). Also, consider issues with motor brushes (remove/replace brushes), motor bearings (test/repair/replace), or the motor itself (test/repair/replace).